A kind of polycarboxylate superplasticizer composition and its application

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of reducing work efficiency, unfavorable to the consumption of bentonite, and the release rate and effect of polycarboxylic acid water reducing agent cannot be guaranteed, so as to reduce harmful losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

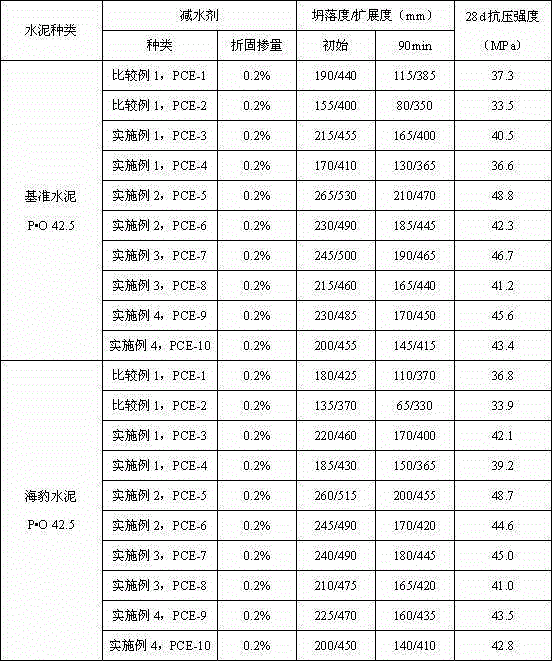

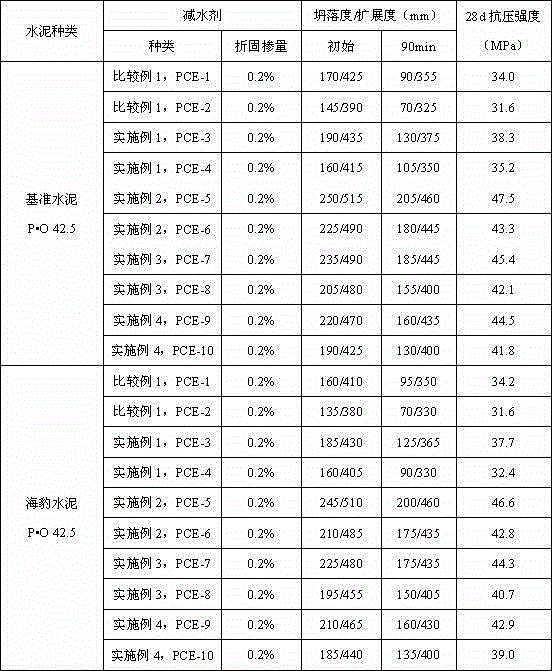

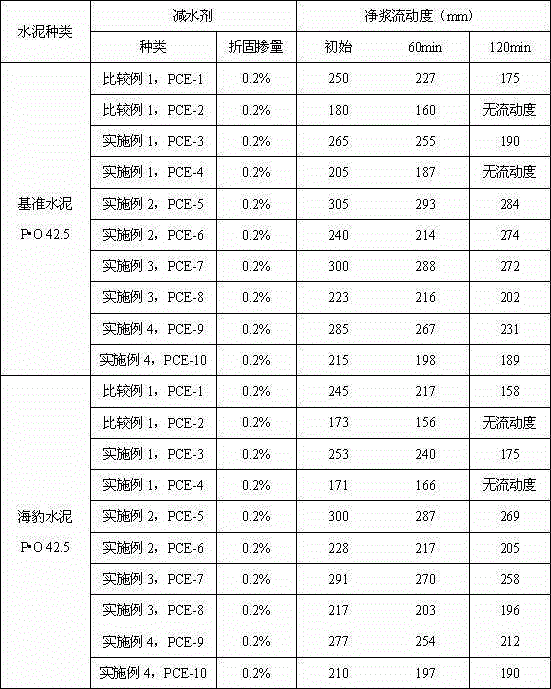

Examples

Embodiment 1

[0039] Add 800 g of a 40% concentration trimethylamine aqueous solution to a 2 L three-necked flask equipped with a thermometer, a condenser, an agitator and a peristaltic metering pump, and slowly add 100 g of epichlorohydrin dropwise while maintaining a certain temperature and stirring. After the dropwise addition was completed, the temperature was controlled at 25° C. to continue the constant temperature reaction for 2.5 hours. Residual trimethylamine was removed in vacuum after the reaction was completed to obtain the intermediate product glycidyltrimethylammonium chloride. Add 500 g of pre-prepared polyvinyl alcohol solution to a 1 L three-necked flask equipped with a thermometer, a condenser, a stirrer and a peristaltic metering pump, and slowly raise the temperature to 70-100°C. Then, 1 g of glycidyltrimethylammonium chloride was slowly added dropwise to the polyvinyl alcohol solution. After the dropwise addition, the pH value of the system was adjusted to 10.0 and the...

Embodiment 2

[0043]Add 500 g of a 40% concentration trimethylamine aqueous solution to a 2 L three-necked flask equipped with a thermometer, a condenser, an agitator and a peristaltic metering pump, and slowly add 100 g of epichlorohydrin dropwise while maintaining a certain temperature and stirring. After the dropwise addition, the temperature was controlled at 30° C. to continue the constant temperature reaction for 3 hours. Residual trimethylamine was removed in vacuum after the reaction was completed to obtain the intermediate product glycidyltrimethylammonium chloride. Add 500 g of pre-prepared polyvinyl alcohol solution into a three-necked flask equipped with a thermometer, a condenser, a stirrer and a peristaltic metering pump, and slowly raise the temperature to 70-100°C. Then, 5 g of glycidyltrimethylammonium chloride was slowly added dropwise to the polyvinyl alcohol solution. After the dropwise addition, the pH value of the system was adjusted to 10.0 and the reaction was stirr...

Embodiment 3

[0047] Add 300 g of a 40% concentration trimethylamine aqueous solution to a 2 L three-necked flask equipped with a thermometer, a condenser, an agitator and a peristaltic metering pump, and slowly add 100 g of epichlorohydrin dropwise while maintaining a certain temperature and stirring. After the dropwise addition was completed, the temperature was controlled at 32° C. to continue the constant temperature reaction for 3.5 hours. Residual trimethylamine was removed in vacuum after the reaction was completed to obtain the intermediate product glycidyltrimethylammonium chloride. Add 500 g of pre-prepared polyvinyl alcohol solution into a three-necked flask equipped with a thermometer, a condenser, a stirrer and a peristaltic metering pump, and slowly raise the temperature to 70-100°C. Then, 25 g of glycidyltrimethylammonium chloride was slowly added dropwise to the polyvinyl alcohol solution. After the dropwise addition, the pH value of the system was adjusted to 10.5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com