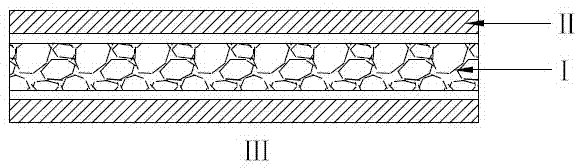

Ultrathin metal sheet sandwich structural body and preparation method thereof

A sandwich structure, metal sheet technology, applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve problems such as insufficiency, and achieve the effect of high fire rating, light weight and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The FR100 series PET structural foam (specific gravity of 100kg / m 3 ) is cut into 4mm thickness and surface size of 320mm*250mm (weight is 32g) as a foam with independent closed-cell cells, and the elastic modulus of the foam is 70MPa according to ASTM D 638 test; then in the foam The upper and lower surfaces are directly coated with a thermoplastic resin adhesive layer;

[0042] Cut the 7075 series aluminum alloy of Southwest Aluminum into 0.5mm thickness and 320mm*250mm surface size (weight is 2 pieces) as ultra-thin metal sheet material, the modulus of ultra-thin metal sheet material is 72GPa; a thin metal sheet material is laminated on both upper and lower surfaces of the foam coated with a thermoplastic resin adhesive layer to provide a laminate;

[0043] Prepare a steel flat mold with levelness and smoothness ranging from 5 to 13, and the steel flat mold has a concave-convex surface, and the thickness can be controlled from 1 to 10mm. Place the above-mentioned la...

Embodiment 2

[0046] Rohacell's 71WF type PMI structural foam (specific gravity 70kg / m 3 ) is cut into 4mm thickness and 320mm*250mm surface size (weight is 23g) as a foam with independent closed-cell cells, and the elastic modulus of the foam is 92MPa according to ASTM D 638 test; then in the foam The upper and lower surfaces are directly coated with a thermosetting resin adhesive layer;

[0047] Cut the 6061 series aluminum alloy sheet of Southwest Aluminum into 0.4 thickness and 320mm*250mm surface size (weight is 89g, 2 pieces) as ultra-thin metal sheet material, and the modulus of ultra-thin metal sheet material is 75GPa; Laminating the ultra-thin metal sheet material on the upper and lower surfaces of the foam coated with a thermosetting resin adhesive layer to provide a laminate;

[0048] Prepare a steel flat mold with levelness and smoothness ranging from 5 to 13, and the steel flat mold has a concave-convex surface, and the thickness can be controlled from 1 to 10mm. Place the abo...

Embodiment 3

[0051] The method of film lamination is used to compound discontinuous reinforcing fibers and thermoplastic resin films, and a layer of reinforcing fiber materials sandwiched by two layers of thermoplastic resin films is formed into a core material of thermoplastic discontinuous reinforcing fibers after being pressurized and heated by steel belt rollers; The specific gravity of the core material is 1.0, and the thickness is 5.0mm; the melting point or load deformation temperature or glass transition temperature of the thermoplastic resin is above 80°C; then the upper and lower surfaces of the core material are directly coated with a thermoplastic resin adhesive layer;

[0052] Cut the 304 stainless steel strip from Shanxi Titanium Steel Stainless Steel Precision Co., Ltd. into 0.2mm thickness and 320mm*250mm surface size (weight is 124g, 2 pieces) as ultra-thin metal sheet material, and the modulus of ultra-thin metal sheet material It is 205GPa; the ultra-thin metal sheet mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com