Aluminum foil/carbon composite current collector, its preparation method and lithium ion battery

A lithium-ion battery and current collector technology, applied in the field of electrochemistry, can solve the problems of battery stability and life reduction, damage to aluminum foil, technical complexity, etc., to improve cycle stability and life, reduce contact internal resistance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

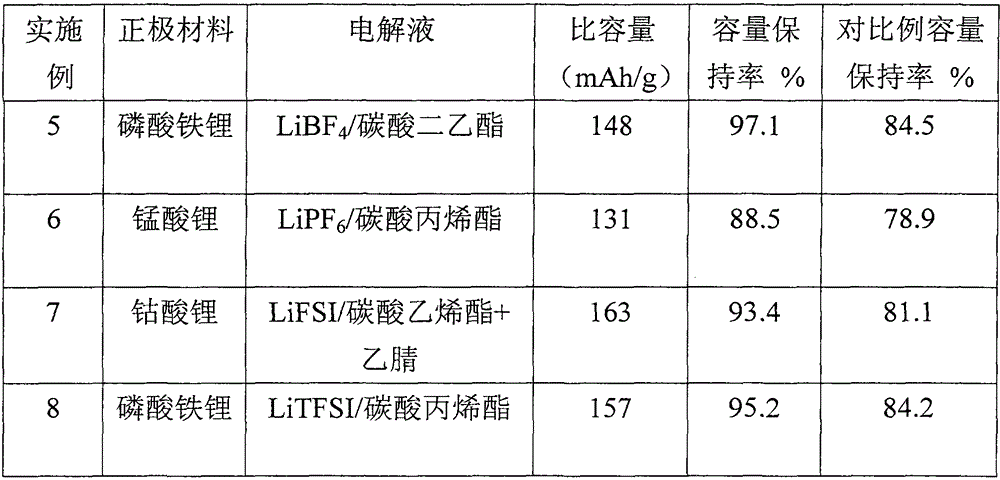

Examples

preparation example Construction

[0018] Preparation of aluminum foil / carbon composite current collector:

[0019] The preparation method of aluminum foil / carbon composite current collector of the present invention roughly comprises the following steps:

[0020] (a) Decontamination and drying: First, use ethanol, acetone and deionized water to remove the oil stains on the aluminum foil in an ultrasonic cleaner, and dry it in a drying oven at 80-100°C for 5-10 minutes. The thickness of aluminum foil is generally commonly used 9um, 12um, 16um (industry standard).

[0021] (b) Ion implantation: take out the dried aluminum foil, put it into the ion implantation equipment, seal the ion implantation equipment and pass one of nitrogen, helium or argon as a protective gas, and use the method of high-speed ion implantation. Carbon elements are implanted into one side of the aluminum foil to obtain an aluminum foil / carbon composite current collector, wherein the amount of ion implantation is 1×10 -6 ~1×10 -4 g / cm 2 ...

Embodiment 1

[0040] The preparation method of the aluminum foil / carbon composite current collector in Example 1 of the present invention comprises the following steps:

[0041] (a) Decontamination and drying: First, use ethanol, acetone and deionized water to sonicate the aluminum foil in an ultrasonic cleaner to remove oil stains, and then dry it in a vacuum drying oven at 80°C for 5 minutes;

[0042] (b) Ion implantation: take out the dried aluminum foil, put it into the ion implantation equipment, seal the equipment and feed nitrogen gas as a protective gas, and use high-speed ion implantation to inject carbon elements into one side of the aluminum foil to obtain aluminum foil / Carbon composite current collector, wherein the amount of ion implantation is 1×10 -6 / cm 2 , the injection time is 20 minutes, and the injection energy is 800eV;

[0043](c) Corrosion and drying: After the ion implantation is completed, let the equipment cool down to room temperature naturally, open the cover,...

Embodiment 2

[0045] The preparation method of the aluminum foil / carbon composite current collector in Example 2 of the present invention comprises the following steps:

[0046] (a) Decontamination and drying: First, use ethanol, acetone and deionized water to sonicate the aluminum foil in an ultrasonic cleaner to remove oil stains, and then dry it in a vacuum drying oven at 100°C for 5 minutes;

[0047] (b) Ion implantation: take out the dried aluminum foil, put it into the ion implantation equipment, seal the equipment and pass helium gas as a protective gas, and use high-speed ion implantation to inject carbon elements into one side of the aluminum foil to obtain the aluminum foil / carbon composite current collector, wherein the amount of ion implantation is 1×10 -4 / cm 2 , the injection time is 1 minute, and the injection energy is 1500eV;

[0048] (c) Corrosion and drying: After the ion implantation is completed, let the equipment cool down to room temperature naturally, open the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com