Mixed cathode material for lithium ion batteries and preparation method thereof

A lithium-ion battery and positive electrode technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low consistency, cycle life, and limited safety improvement, and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

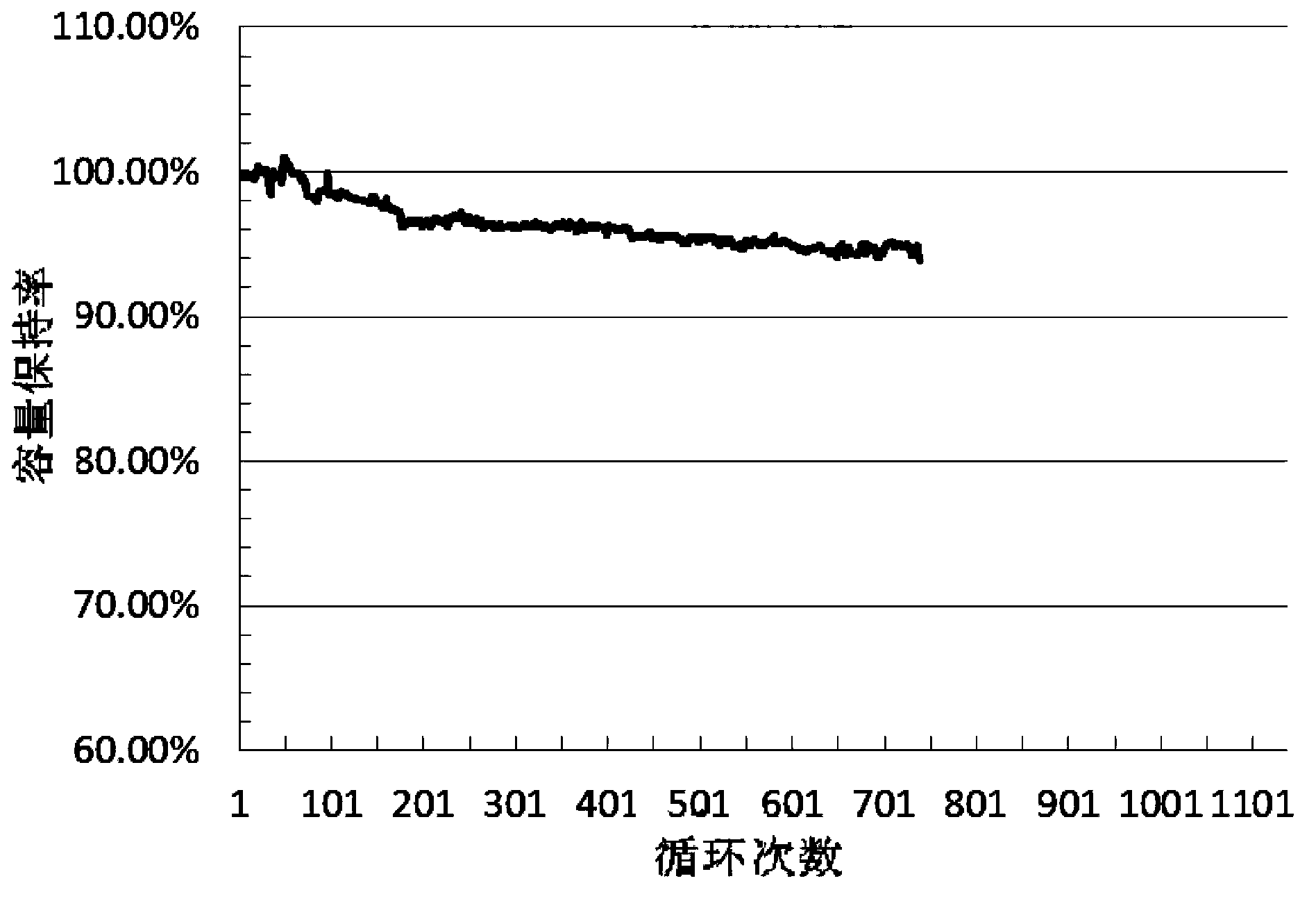

Embodiment 1

[0050] 1. Raw material A is selected as LiMn 1.9 Al 0.05 co 0.05 o 3.98 f 0.02 , average particle size 10μm, specific surface area 0.35m 2 / g, raw material B is LiNi 0.333 co 0.329 mn 0.333 Mg 0.004 o 2 , average particle size 10μm, specific surface area 0.30m 2 / g;

[0051] 2. Put 50wt% of raw material A and 50wt% of raw material B into a polyethylene container with a stirrer, add deionized water equivalent to 3 times the weight of the powder, start the stirrer, and stir at a speed of 500rpm for 20min.

[0052] 3. Add liquid coating agents E and F dropwise to the polyethylene container filled with materials and dispersants through two peristaltic pumps, wherein E is a lithium hydroxide aqueous solution with a concentration of 0.2mol / l, and F is a concentration of 0.2mol / l Aluminum nitrate aqueous solution. Control the dripping amount of the aluminum nitrate aqueous solution so that the aluminum element in the dripping solution accounts for 1.0% of the molar amo...

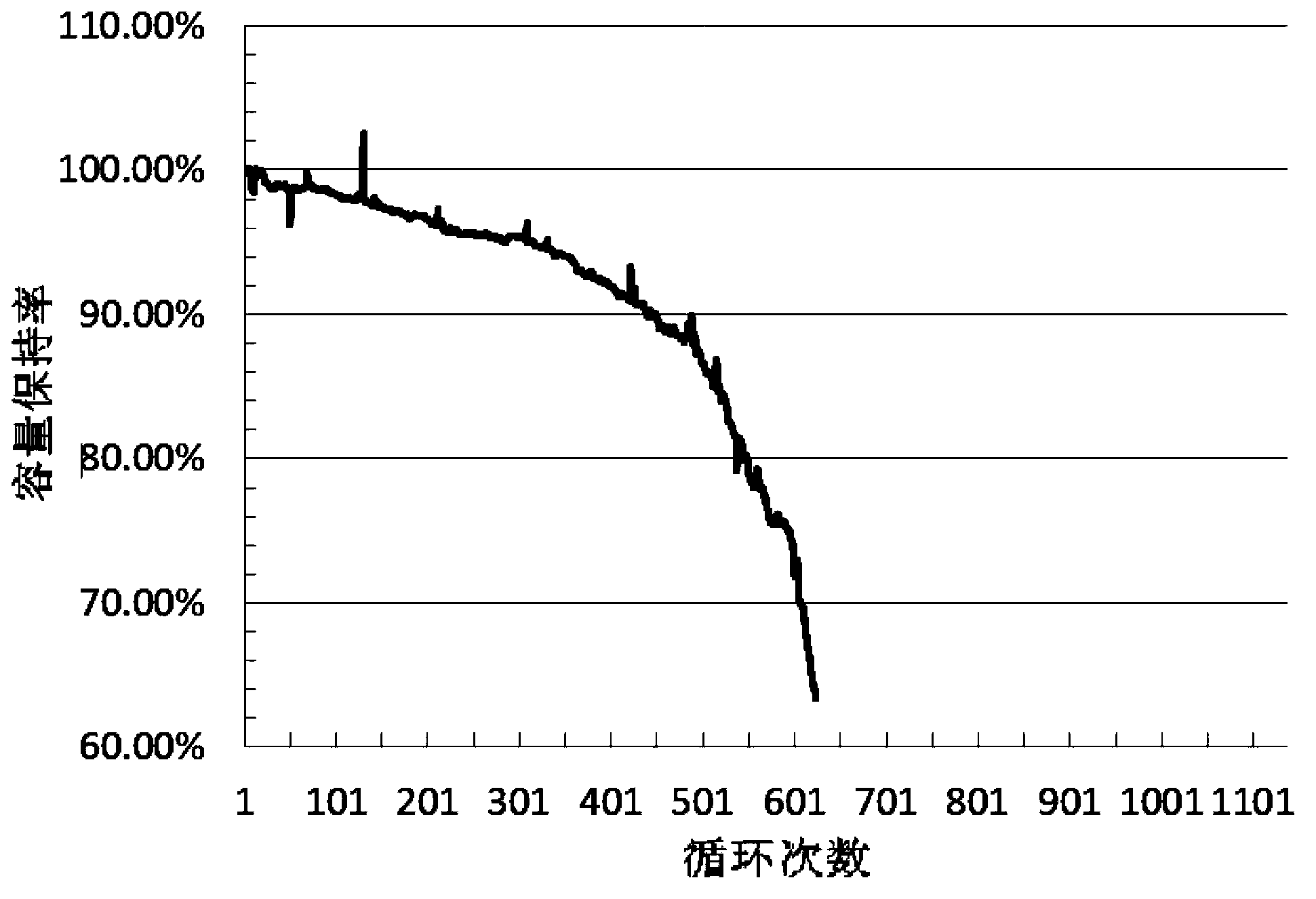

Embodiment 2

[0055] 1. Raw material A is selected as LiMn 1.9 Al 0.05 Mg 0.05 o 3.98 f 0.02 , average particle size 10μm, specific surface area 0.35m 2 / g, raw material B is LiNi 0.333 co 0.329 mn 0.333 Ti 0.002 Mg 0.002 o 2 , average particle size 10μm, specific surface area 0.30m 2 / g;

[0056] 2. Put 50wt% of raw material A and 50wt% of raw material B into a polyethylene container with a stirrer, add deionized water equivalent to 3 times the weight of the powder, start the stirrer, and stir at a speed of 500rpm for 20min.

[0057] 3. Liquid coating agents E and F are added dropwise to the polyethylene container filled with materials and dispersants through two peristaltic pumps, wherein E is the ammonium phosphate aqueous solution with a concentration of 0.2mol / l, and F is the ammonium phosphate solution with a concentration of 0.2mol / l. Aqueous solution of aluminum nitrate. Control the dripping amount of the aluminum nitrate aqueous solution so that the aluminum element...

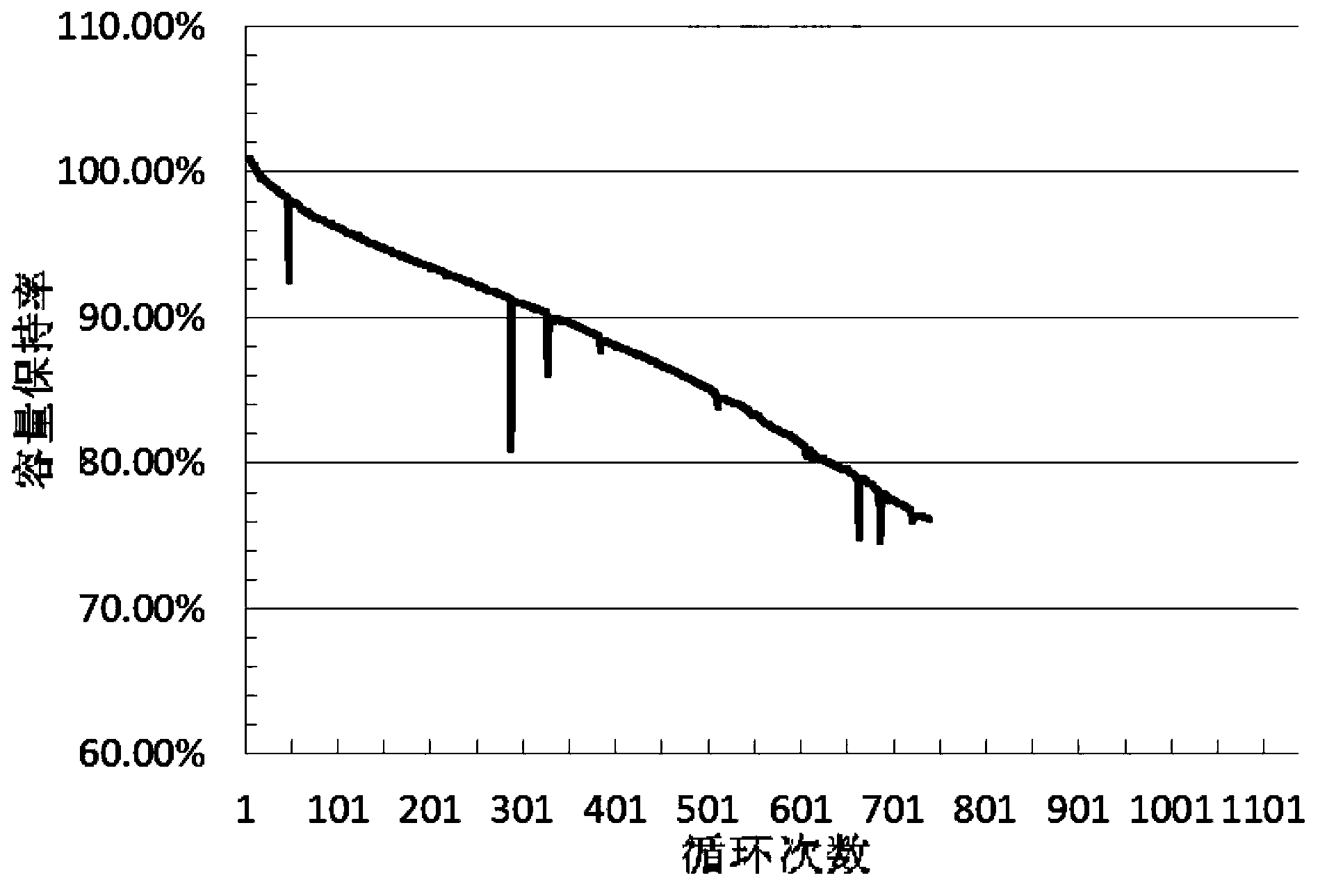

Embodiment 3

[0060] 1. Raw material A is selected as LiMn 1.9 Al 0.05 Mg 0.05 o 3.98 f 0.02 , average particle size 10μm, specific surface area 0.35m 2 / g, raw material B is LiNi 0.333 co 0.329 mn 0.333 Ti 0.002 Mg 0.002 o 2 , average particle size 10μm, specific surface area 0.30m 2 / g, raw material C-site LiNi 0.5 co 0.196 mn 0.3 Al 0.004 o 2 , average particle size 10μm, specific surface area 0.35m 2 / g;

[0061] 2. Put 50wt% of raw material A, 30wt% of raw material B, and 20wt% of raw material C into a polyethylene container with a stirrer, add deionized water equivalent to 3 times the weight of the powder, start the stirrer, and stir at a speed of 500rpm for 20min .

[0062] 3. Add liquid coating agents E and F dropwise to the polyethylene container filled with materials and dispersants through two peristaltic pumps, wherein E is a lithium hydroxide aqueous solution with a concentration of 0.2mol / l, and F is a concentration of 0.2mol / l aqueous solution of zinc ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com