Organic-inorganic composite lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and inorganic composite technology, which is applied to battery components, chemical instruments and methods, circuits, etc., can solve the problems that the diaphragm is easy to be melted by high temperature, explode, and discharge power is large, and achieve micropore penetration and high temperature good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Polyethylene (PE) 28g, SiO 2 Add 2.1g and 39.2g of dioctyl phthalate (DOP) into the internal mixer, and stir at 180°C for 0.5h to obtain a homogeneous solution;

[0038] 2. Keep the obtained homogeneous solution at 200°C for 5 minutes under a pressure of 2Mpa, press it into a flat film with a thickness of 100 μm, put the flat film into 20°C water for rapid cooling, and take it out after holding it for 10 minutes;

[0039] 3. Put the cooled flat film into cyclohexane for extraction, change the cyclohexane solution every 8 hours, extract three times in total, put the extracted film in an oven at 60°C for 6 hours, take it out, and obtain the compound Polyethylene diaphragm.

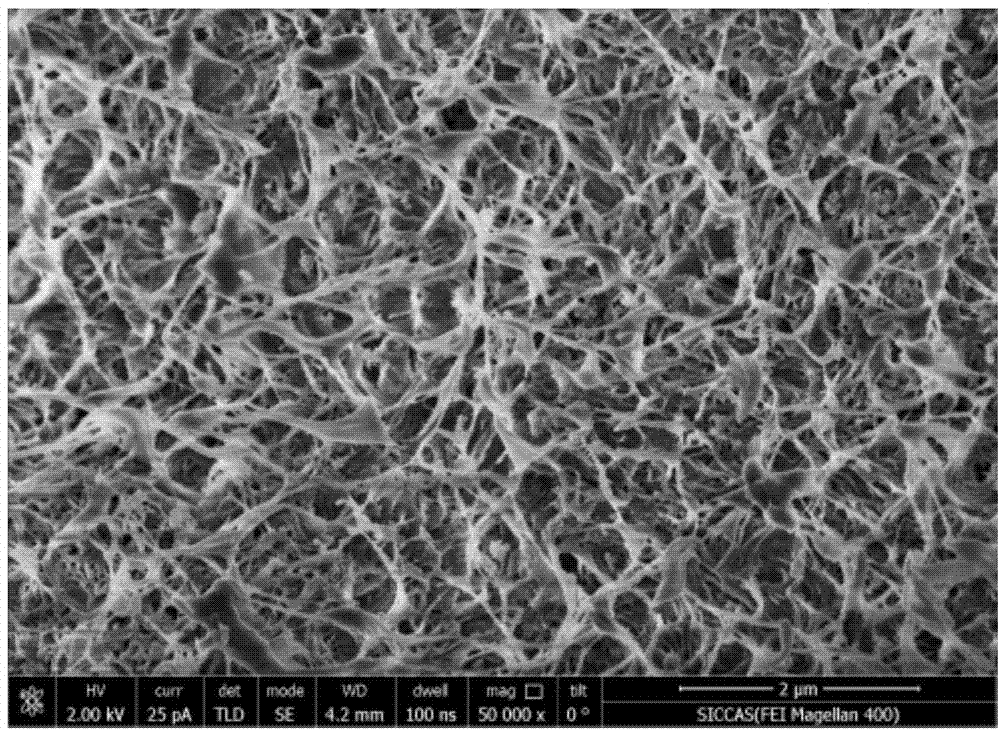

[0040] The cross-sectional scanning electron micrograph of gained composite polyethylene diaphragm is as follows figure 2 shown by figure 2 It can be seen that the section of the diaphragm is loose and porous, and the pore size is large; the test results of the thickness, pore size, liquid abs...

Embodiment 2

[0042] 1. Polyethylene (PE) 26g, SiO 2 Add 3.25g and 35.75g of dioctyl phthalate (DOP) into the internal mixer, and stir at 200°C for 0.5h to obtain a homogeneous solution;

[0043] 2. Keep the obtained homogeneous solution at 200°C for 5 minutes under a pressure of 2Mpa, press it into a flat film with a thickness of 100 μm, put the flat film into 20°C water for rapid cooling, and take it out after holding it for 10 minutes;

[0044]3. Put the cooled flat film into cyclohexane for extraction, change the cyclohexane solution every 8 hours, extract three times in total, put the extracted film in an oven at 60°C for 6 hours, take it out, and obtain the compound Polyethylene diaphragm.

[0045] The cross-sectional scanning electron micrograph of gained composite polyethylene diaphragm is as follows image 3 shown by image 3 It can be seen that the section of the diaphragm is loose and porous, and the pore size is large; the test results of the thickness, pore size, liquid abso...

Embodiment 3

[0053] 1. Polyethylene (PE) 26g, SiO 2 Add 3.25g and 35.75g of dioctyl phthalate (DOP) into the internal mixer, and stir at 180°C for 1 hour to obtain a homogeneous solution;

[0054] 2. For the obtained homogeneous solution, heat it for 5 minutes at 200°C and a pressure of 2Mpa, press it into a flat film with a thickness of 500 μm, put the flat film into 20°C water for rapid cooling, and take it out after holding it for 10 minutes;

[0055] 3. Fix the cooled flat film on a stretching machine for two-way thermal stretching. The temperature of the stretching machine is 120°C, and the stretching ratio is 1:5. After stretching, remove the stretched film and put it into ethanol for extraction. , change the ethanol solution every 8 hours, and extract three times in total; then put the extracted film in an oven at 60°C for 6 hours, take it out, and obtain a composite polyethylene diaphragm.

[0056] The test results about the thickness, pore size, liquid absorption rate and heat sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com