Self-adhesive label

A label and adhesive layer technology, applied in the field of self-adhesive labels, can solve the problems of emulsifier pollution and poor temperature resistance, and achieve the effect of good temperature resistance and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

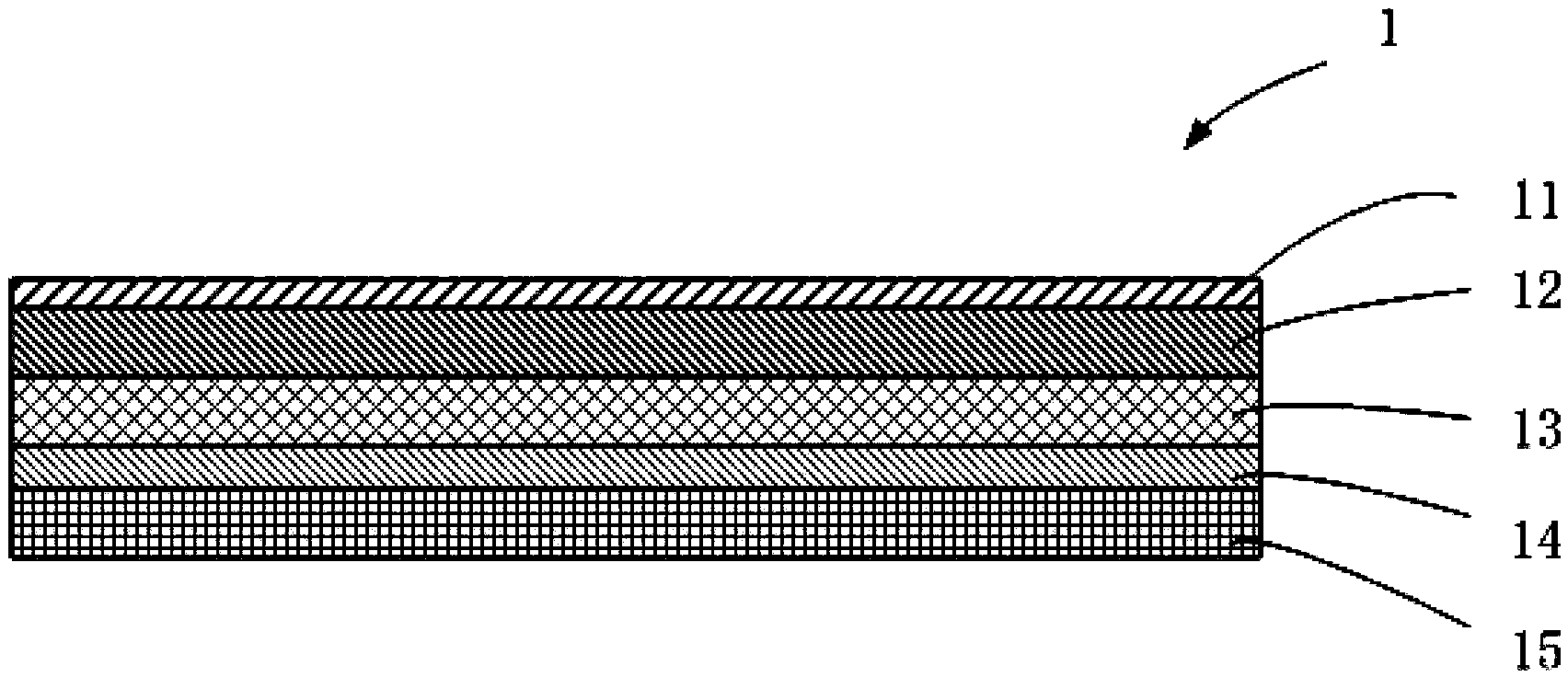

[0015] Please refer to figure 1 , the self-adhesive label 1 provided in this embodiment includes a face paper layer 12, an adhesive layer 13, a silicone oil layer 14 and a backing paper layer 15 from top to bottom, and the adhesive layer 13 is made of a solvent-free acrylic pressure-sensitive adhesive , The face paper layer 12 also includes a film layer 11.

[0016] The upper surface of the face paper layer 12 is used for receiving printed images, while the back is used for receiving glue and finally applying it to the pasted object. Therefore, the material of the surface paper layer 12 should meet the requirements of being able to adapt to printing and printing, having good ink receptivity, and having sufficient strength to accept various processing, such as die cutting, waste discharge, slitting, punching and labeling. Therefore, preferably, in this embodiment, the surface paper layer 12 is made of mirror coated paper, coated paper, fluorescent paper, aluminum foil paper or...

Embodiment 2

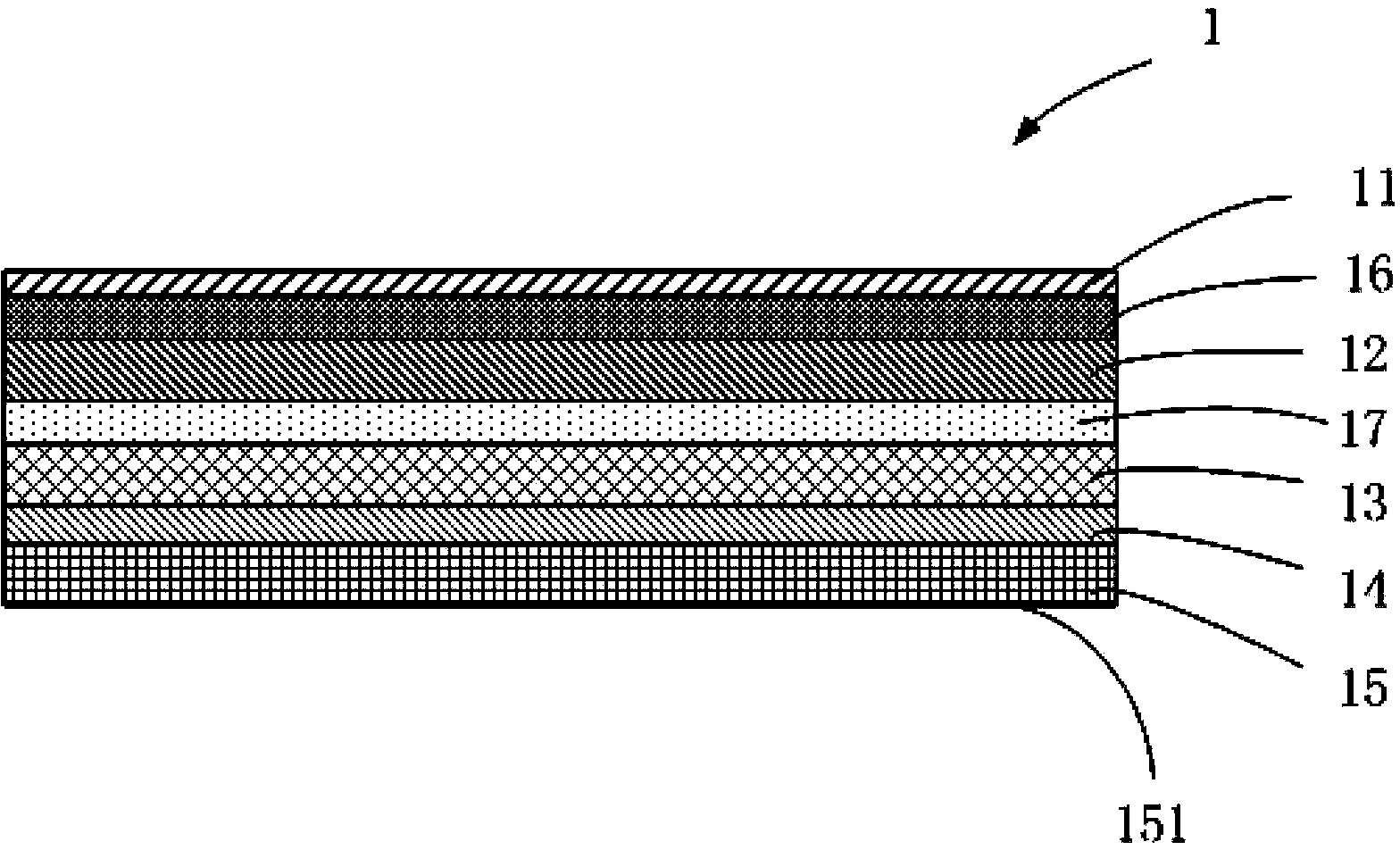

[0021] Please refer to figure 2 , the self-adhesive label 1 provided in this embodiment has the same basic structure as that of the self-adhesive label 1 in Embodiment 1, the difference is that in this embodiment, between the film layer 11 and the face paper layer 12, a There is a surface coating 16, and a coating layer 17 is also included between the surface paper layer 12 and the adhesive layer 13, and a back printing 151 is included under the bottom paper layer 15. The surface coating 16 is used to change the surface characteristics of the face paper layer 12, such as improving the surface tension, changing the color, adding a protective layer, etc., so that it can better accept ink and be easy to print, so as to prevent dirt, increase ink adhesion and The purpose of preventing the printed graphics from falling off. Surface coating is mainly used for non-absorbent materials, such as aluminum foil, aluminized paper and various film materials. The effect of the coating pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com