Pressure sensor with long service life and high sensitivity

A pressure sensor and sensitivity technology, which is applied in the direction of instruments, measuring force, and measuring devices, can solve the problems of complex integrated circuits, low comprehensive precision, and complex structures, and achieve simple integrated circuit structures, high resolution of pressure points, and improved Effect of gage factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

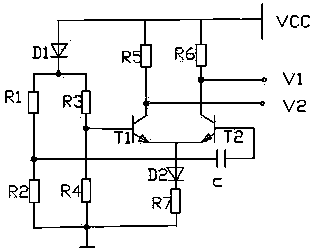

[0014] Such as figure 1 Shown, the present invention comprises resistor R1, resistor R2, resistor R3, resistor R4, resistor R5, resistor R6, resistor R7, transistor T1, transistor T2, diode D1, diode D2 and capacitor C, and the anode of diode D2 connects transistor T1 and The emitter of the transistor T2 and the cathode of the diode D2 are connected to the resistor R7; the diode D1 and the diode D2 are Zener diodes; the resistances of the resistors R1, R2, R3 and R4 are equal. The common end of the resistor R6 and the transistor T2 is connected to the output port V1, and the common end of the resistor R5 and the transistor T1 is connected to the output port V2. In this embodiment, resistor R1, resistor R2, resistor R4 and resistor R3 are sequentially connected in series to form a closed loop, and the common terminal of resistor R2 and resistor R4 is sequentially connected in series with resistor R7, diode D2 and the emitter of transistor T1. In this embodiment, the base set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com