Array type flexible force sensor

A flexible force and array-type technology, applied in the field of array-type flexible force-sensing sensors, can solve the problems that the surface microscopic shape is easily damaged by pressure, the sensor has a large difference in the initial resistance, and the roughness of the contact surface is difficult to achieve small hysteresis and extended The effects of longevity and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

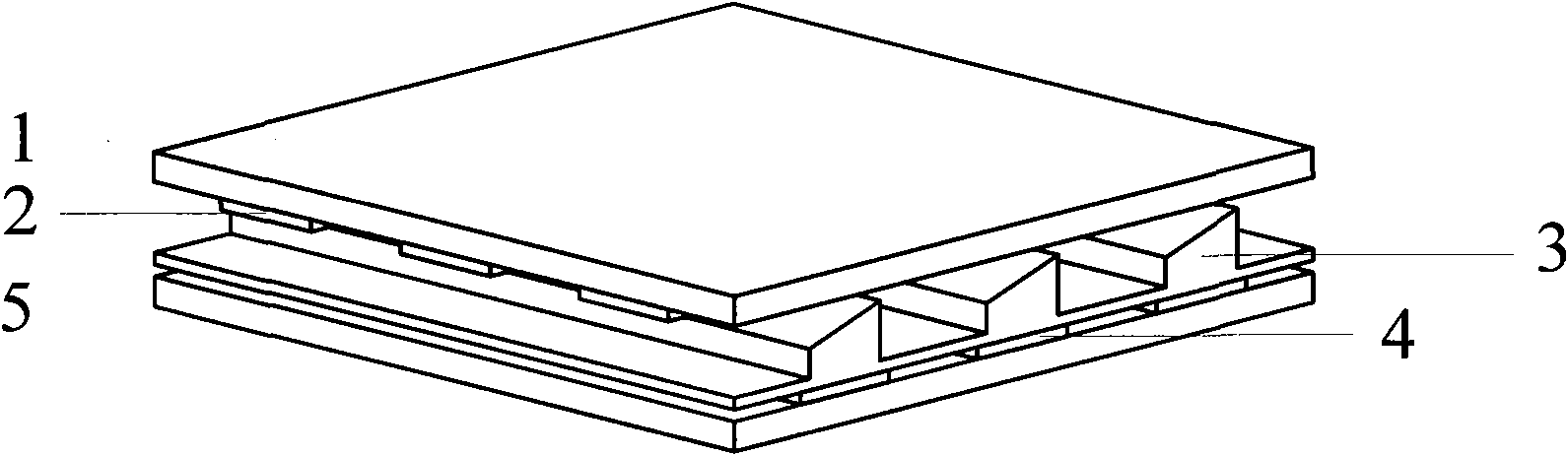

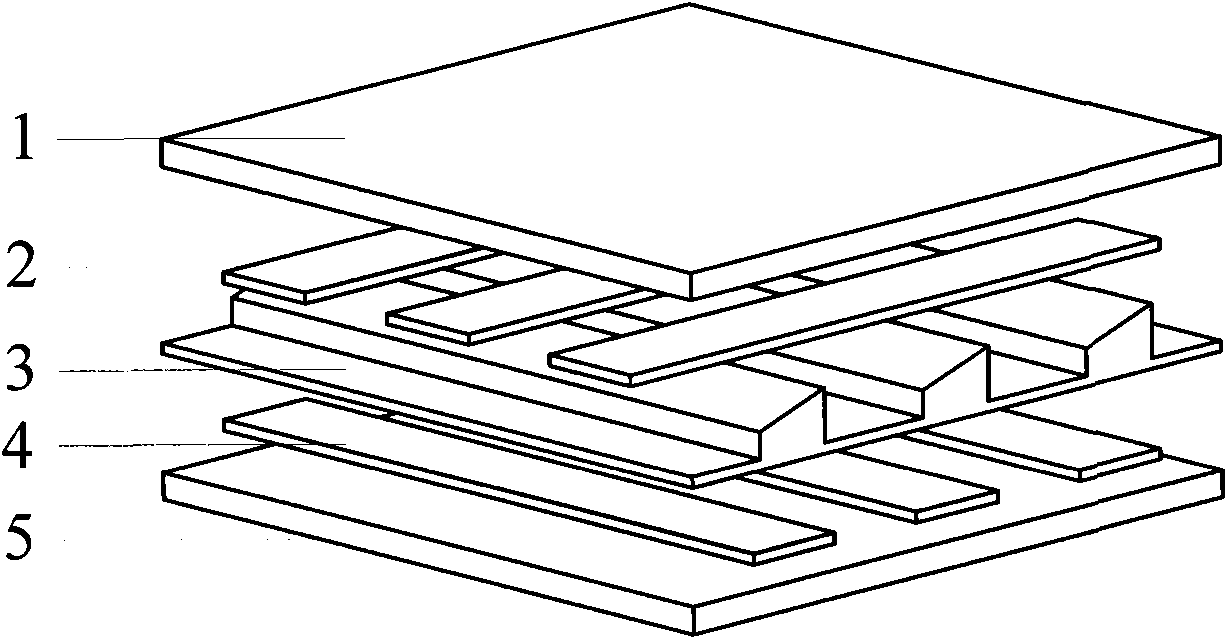

[0030] Such as figure 2 and image 3 , the array type flexible force-sensitive sensor that present embodiment 1 provides, it comprises:

[0031] The array type flexible force sensitive sensor provided by the present invention comprises:

[0032] An upper insulating protective layer 1 and parallel metal row electrodes 2 patterned on the lower surface of the upper insulating protective layer 1;

[0033] The lower insulating protective layer 5 and the parallel metal column electrodes 2 patterned on the upper surface of the lower insulating protective layer 5;

[0034] and

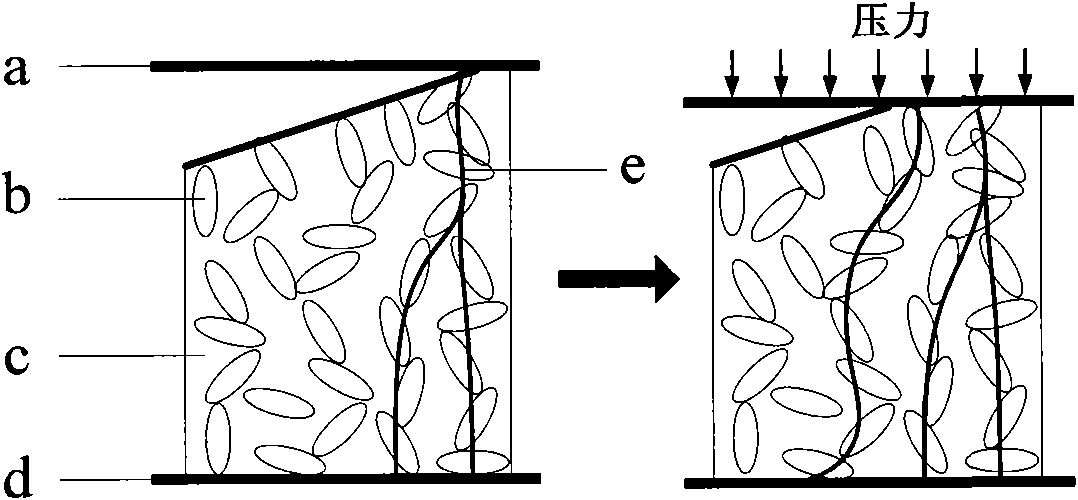

[0035] A first sensitive film layer 3 positioned between the parallel metal row electrodes and the parallel metal column electrodes; the first sensitive film layer 3 is composed of a filled sensitive material layer 31 and attached to the filled sensitive material layer 31 is composed of a filled sensitive material convex strip 32 or a filled sensitive material convex block 33 on the upper surface; the lon...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is that: the first sensitive film layer 3 is prepared by compression molding. The first sensitive film layer 3 is a film layer made of a filled conductive composite material in which conductive particles b are uniformly dispersed in an insulating flexible base material c. The conductive particle b is selected from carbon black, the insulating flexible base material c is made of polysilicone rubber, and the mass ratio of the conductive particle b to the insulating flexible base material c is 15:100; the filled conductive composite material is prepared by a solution method.

[0051] The mold required for film molding is manufactured by machining or MEMS technology. Put the filled conductive composite material into a compression molding machine, heat to 200° C., wait for the material filled conductive composite material to melt, apply pressure to the compression molding machine, cool the material to room temperature, ...

Embodiment 3

[0053] The difference between this embodiment and Embodiments 1 and 2 is that the convex strips 32 of the first sensitive film layer 3 are convex strips with a tapered longitudinal section or convex strips with a zigzag longitudinal section. The conductive particle b is selected from carbon black, the insulating flexible base material c is selected from polysilicone rubber, and the mass ratio of the conductive particle b to the insulating flexible base material c is 0.1:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com