Method for drying, screening and collecting graphite powder

A technology of graphite powder and graphite powder, which is applied in the direction of solid separation, drying of solid materials, and arrangement of drying gas, which can solve the problems of high labor intensity, low degree of automation, and low product quality, and achieve high drying efficiency and high product grade. The effect of many, high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

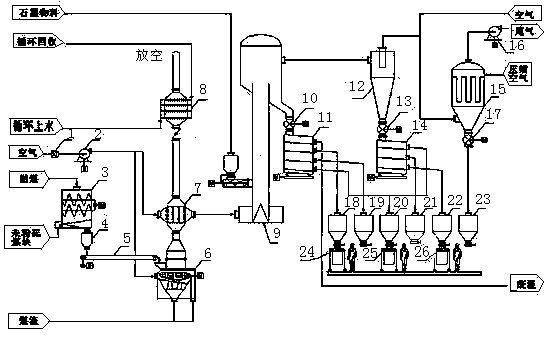

[0026] Below in conjunction with accompanying drawing, technological process of the present invention is further described again:

[0027] After the lump coal is pulverized by the coal crusher 3, it passes through the pulverized coal buffer tank 4, passes through the belt conveyor 5, and enters the chain furnace 6 as fuel. At the same time, the air is filtered by the air filter 1, pressurized by the blower 2, and divided into two paths. ; All the way directly into the chain furnace 6 as combustion air. The 750-820°C high-temperature flue gas generated in the chain furnace 6 first enters the air heat exchanger 6 to heat the air to 400°C as a drying medium, and the low-temperature flue gas after heat exchange enters the process water heat exchanger 8 as a heating medium for the process water; The other way enters the air heat exchanger 7 for heat exchange. The high-temperature air heated to 400°C by the air heat exchanger 7 enters the micropowder dryer 9 (patent number: 02 2 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com