Electroplating liquid of multi-layer cyanide-free electroplated copper-tin alloy coating, electroplating technology and coin thereof

A technology for electroplating copper and tin alloys, applied in coins, clothing, jewelry, etc., can solve the problems of cyanide-free electroplating of brass tin, such as inability to plate thick plating and unevenness, and improve the plating environment, reduce management costs, and reduce The effect of environmental influence pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

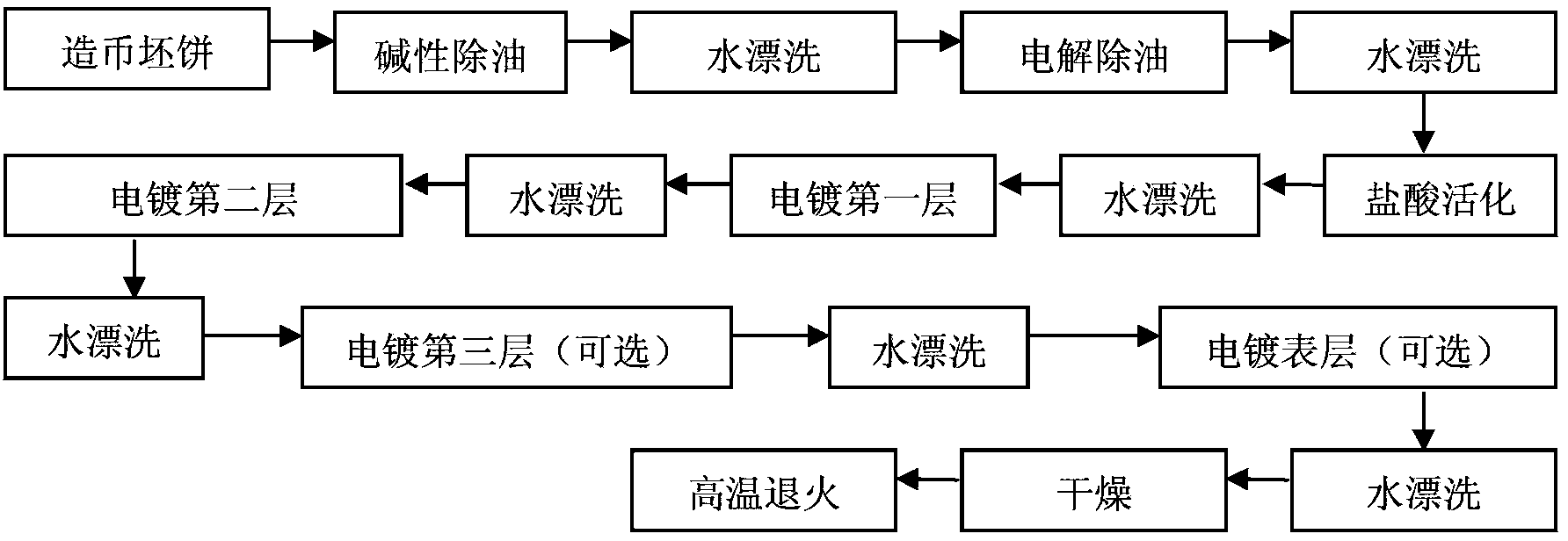

[0084] The low-carbon steel coinage blank is used as the substrate, the first layer and the second layer are electroplated sequentially on it, and then it is used as a product. The specific steps are as follows:

[0085] (1) Alkaline degreasing

[0086] Put the coinage blank into the alkaline degreasing liquid, the degreasing liquid is 50g / L degreasing agent, the temperature is 55°C for 20 minutes, and then rinse with 60°C deionized water;

[0087] (2) Electrodegreasing

[0088] Put the above-mentioned coinage blanks after alkali washing in the electrolytic degreasing liquid, the degreasing liquid is 60g / L degreasing agent, the temperature is 55°C, and the current density is 0.5A / dm 2 , carry out anodic electrolytic cleaning for 20 minutes, and then rinse with deionized water at 60°C;

[0089] (3) Hydrochloric acid activation

[0090] Place the coinage blank after electrolytic degreasing in the HCL solution with a concentration of 350mL / L at a temperature of 20°C for 7 minu...

Embodiment 2

[0102] The low-carbon steel coinage blank is used as the substrate, the first layer and the second layer are electroplated sequentially on it, and then it is used as a product. The specific steps are as follows:

[0103] (1) Alkaline degreasing

[0104] Put the coinage blank into the alkaline degreasing liquid, the degreasing liquid is 60g / L degreasing agent, the temperature is 60°C for 20 minutes, and then rinse with 60°C deionized water;

[0105] (2) Electrodegreasing

[0106] Put the above-mentioned coinage blanks after alkali washing in the electrolytic degreasing liquid, the degreasing liquid is 70g / L degreasing agent, the temperature is 60°C, and the current density is 1.0A / dm 2 , carry out anodic electrolytic cleaning for 20 minutes, and then rinse with deionized water at 60°C;

[0107] (3) Hydrochloric acid activation

[0108] Place the coinage blank after electrolytic degreasing in the HCL solution with a concentration of 480mL / L at a temperature of 25°C for 7 minu...

Embodiment 3

[0120] The low-carbon steel coinage blank is used as the substrate, the first layer and the second layer are electroplated sequentially on it, and then it is used as a product. The specific steps are as follows:

[0121] (1) Alkaline degreasing

[0122] Put the mint blank into the alkaline degreasing liquid, the degreasing liquid is 70g / L degreasing agent, the temperature is 65°C for 20 minutes, and then rinse with 60°C deionized water;

[0123] (2) Electrodegreasing

[0124] Put the above-mentioned mint blanks after alkali washing in the electrolytic degreasing liquid, the degreasing liquid is 80g / L degreasing agent, the temperature is 65°C, and the current density is 1.2A / dm 2 , carry out anodic electrolytic cleaning for 20 minutes, and then rinse with deionized water at 60°C;

[0125] (3) Hydrochloric acid activation

[0126] Put the coinage blank after electrolytic degreasing in the HCL solution with a concentration of 480mL / L at a temperature of 29°C for 7 minutes of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com