Efficient and environment-friendly oil-removing, rust-removing and descaling agent and preparation method thereof

An oxide skin agent and environmentally friendly technology, applied in the field of cleaning agents, can solve problems such as unsafe production process, polluted air, and troublesome cleaning, and achieve the effects of short time required, low environmental pollution, and safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

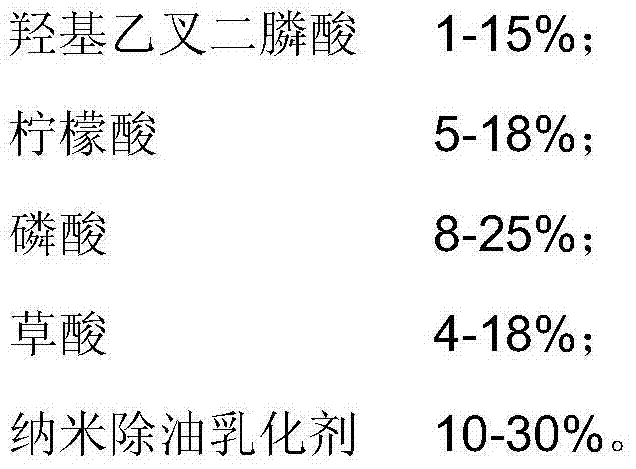

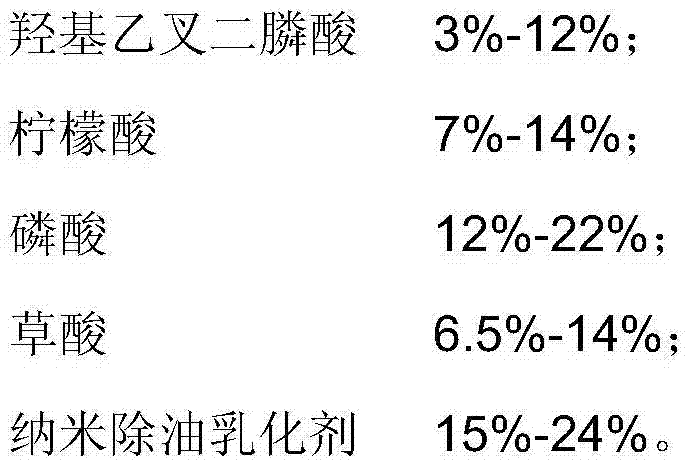

Method used

Image

Examples

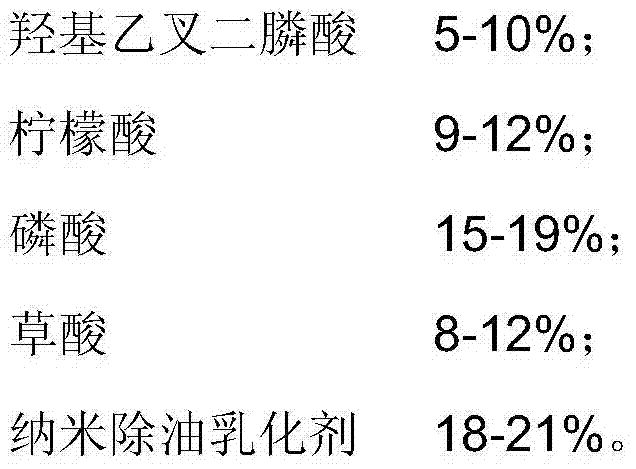

Embodiment 1

[0029] The raw materials of the high-efficiency, environmentally-friendly, oil-removing, rust-removing and scale-removing agent provided in this embodiment are: hydroxyethylidene diphosphonic acid 10%, citric acid 10%, phosphoric acid 15%, oxalic acid 8%, nano-deoiling emulsifier 20%, anticorrosion 1% of the agent, 0.5% of the essence, and the balance of pure water.

[0030] The raw materials were dissolved in the water heated to 70°C by stirring according to the amount taken, and the stirring speed was 100r / min.

[0031] Put the phosphoric acid aqueous solution into the reactor, control the speed of the reactor to 50r / min, put the hydroxyethylidene diphosphonic acid aqueous solution, the citric acid aqueous solution and the oxalic acid aqueous solution into the reactor successively, stir for 40min; then put the nano degreasing emulsifier Put the aqueous solution into the reactor, control the speed of the reactor to 80r / min and stir for 40min; finally adjust the speed of the reacto...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the raw materials of the high-efficiency and environmentally friendly degreasing, rust, and scale removal agent provided by this embodiment are: hydroxyethylidene diphosphonic acid 12%, citric acid 7%, phosphoric acid 22%, 6.5% oxalic acid, 24% nano-degreasing emulsifier, 0.8% preservative, 0.1% flavor, and the balance of purified water.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the raw materials of the high-efficiency and environmentally friendly degreasing, rust, and scale removal agent provided by this embodiment are: hydroxyethylidene diphosphonic acid 3%, citric acid 14%, phosphoric acid 12%, 14% oxalic acid, 15% nano-degreasing emulsifier, 1% preservative, 0.05% flavor, and the balance of pure water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com