Efficient metal component rust removal device for furniture manufacturing

A metal component and furniture manufacturing technology, which is applied in the field of high-efficiency derusting devices for metal components, can solve the problems of no energy saving in pickling and derusting operations, no automatic induction of metal components, and waste of processing time, etc., to achieve energy saving in pickling operations, The effect of preventing waste of electric energy and pickling solution and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

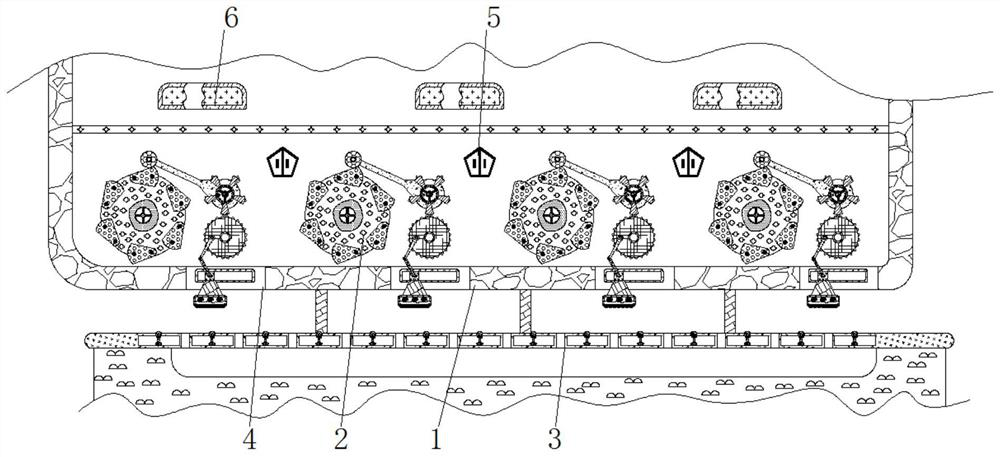

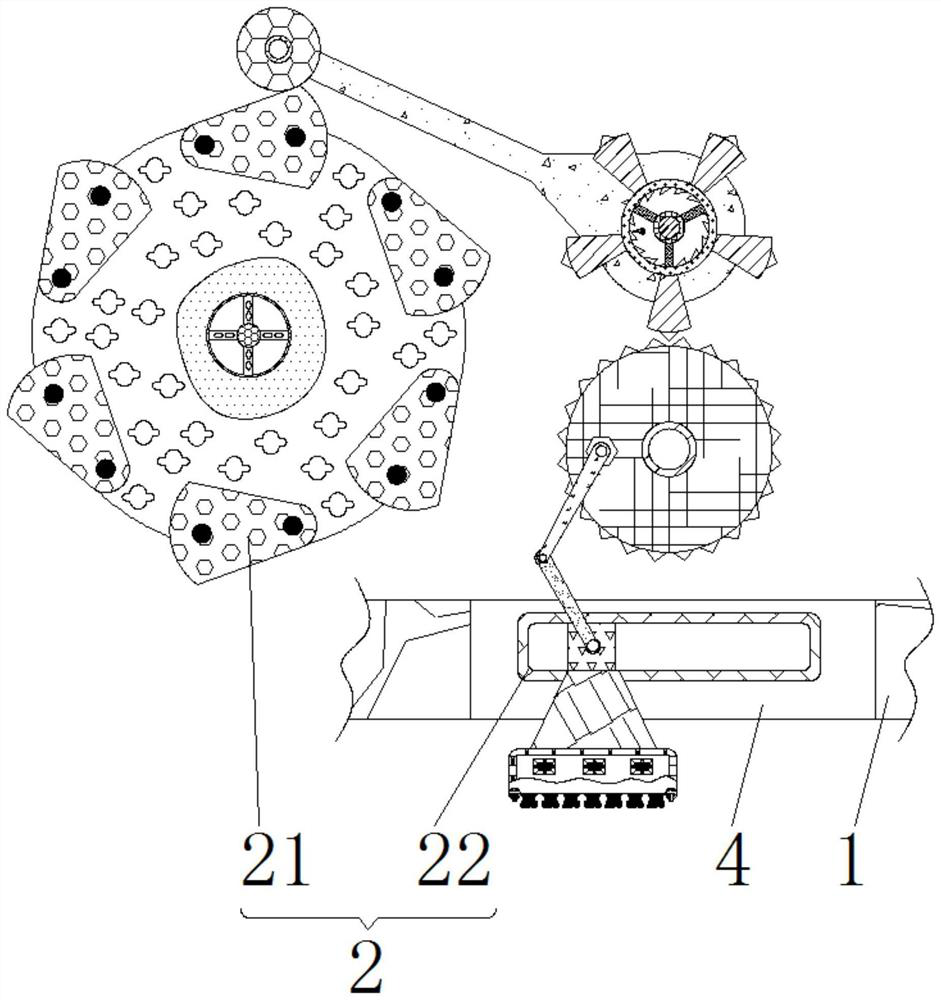

[0028] see Figure 3-7 , a kind of high-efficiency derusting device for metal components used in furniture manufacturing, comprising a housing 1, the interior of the housing 1 is movably connected with a derusting mechanism 2, the derusting mechanism 2 includes a movable assembly 21 for motion adjustment, and rust removal on the surface of metal components With the removed cleaning assembly 22 , the movable assembly 21 is movably connected inside the casing 1 , and the cleaning assembly 22 is movably connected inside the casing 1 .

[0029] Movable assembly 21 comprises motor 211, rotating plate 212, push plate 213, fork 214, roller 215, telescoping rod 216, movable wheel 217, connecting plate 218, gear 219, connecting rod one 2110, connecting rod two 2111, motor 211 is fixed Connected to the inside of the shell 1, the rotating plate 212 is fixedly connected to the outside of the motor 211, the push plate 213 is fixedly connected to the outside of the rotating plate 212, the s...

Embodiment 2

[0033] see Figure 8-9 , a kind of high-efficiency derusting device for metal components used in furniture manufacturing, comprising a housing 1, the interior of the housing 1 is movably connected with a derusting mechanism 2, the derusting mechanism 2 includes a movable assembly 21 for motion adjustment, and rust removal on the surface of metal components With the removed cleaning assembly 22 , the movable assembly 21 is movably connected inside the casing 1 , and the cleaning assembly 22 is movably connected inside the casing 1 .

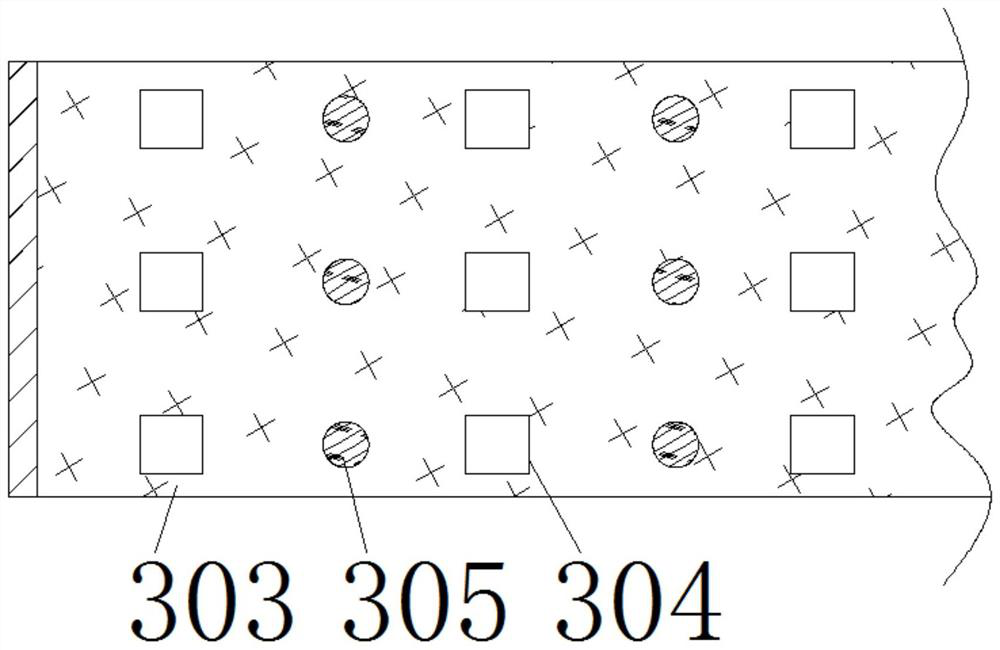

[0034] The exterior of the housing 1 is connected with a sensing support mechanism 3, which includes a fixed platform 301, a liquid storage tank 302, a load-bearing plate 303, a flow port 304, a trigger block 305, a pole 306, a spring 307, and a contact strip 308. The table 301 is fixedly connected to the outside of the shell 1, the liquid storage tank 302 is set on the surface of the fixed table 301, the load-bearing plate 303 is fixedly connecte...

Embodiment 3

[0037] see Figure 1-9 , a kind of high-efficiency derusting device for metal components used in furniture manufacturing, comprising a housing 1, the interior of the housing 1 is movably connected with a derusting mechanism 2, the derusting mechanism 2 includes a movable assembly 21 for motion adjustment, and rust removal on the surface of metal components With the removed cleaning assembly 22 , the movable assembly 21 is movably connected inside the casing 1 , and the cleaning assembly 22 is movably connected inside the casing 1 .

[0038] Movable assembly 21 comprises motor 211, rotating plate 212, push plate 213, fork 214, roller 215, telescoping rod 216, movable wheel 217, connecting plate 218, gear 219, connecting rod one 2110, connecting rod two 2111, motor 211 is fixed Connected to the inside of the shell 1, the rotating plate 212 is fixedly connected to the outside of the motor 211, the push plate 213 is fixedly connected to the outside of the rotating plate 212, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com