Efficient temperature resistance fluid loss agent for drilling fluid and preparation method thereof

A filtrate reducer and drilling fluid technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult exploration technology, unsatisfactory performance, and unstable wellbore walls, so as to reduce labor intensity And equipment investment, good temperature resistance, fast dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

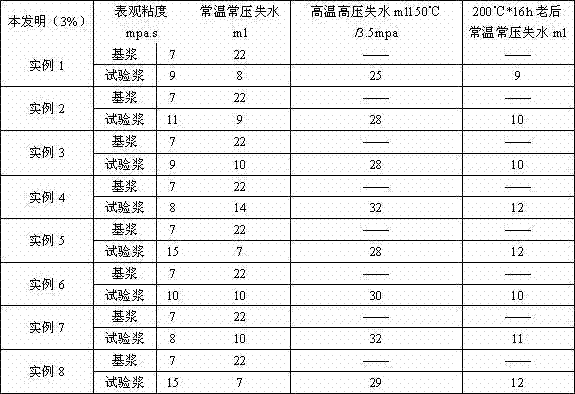

Examples

Embodiment 1

[0010] The preparation method of high-efficiency temperature-resistant fluid loss reducer for drilling fluid: first add 2000kg of water to the reactor, heat up to 50°C, stir and add 150kg of sodium hydroxide, then stir and add 300kg of hydrolyzed polyacrylonitrile sodium salt, and then add 700kg Weathered coal, stirred and heated to 82°C, reacted for 3 hours, the resulting liquid with a concentration of 30% was pumped to the spray drying tower for atomization and drying to obtain spherical fine particles of high-efficiency temperature-resistant fluid loss reducer, the first time The recommended dosage is 3%.

Embodiment 2

[0012] The preparation method of high-efficiency temperature-resistant fluid loss reducer for drilling fluid: first add 2100kg of water to the reactor, heat up to 50°C, stir and add 175kg of sodium hydroxide, then stir and add 300kg of hydrolyzed polyacrylonitrile ammonium salt, and then add 600kg Weathered coal, stirred and heated to 82°C, reacted for 3 hours, the resulting liquid with a concentration of 28% was pumped to the spray drying tower for atomization and drying to obtain spherical fine particles of high-efficiency temperature-resistant fluid loss reducer, the first time The recommended dosage is 3%.

Embodiment 3

[0014] The preparation method of high-efficiency temperature-resistant fluid loss reducer for drilling fluid: first add 2100kg of water to the reactor, heat up to 60°C, stir and add 125kg of sodium hydroxide, then stir and add 250kg of hydrolyzed polyacrylonitrile sodium salt, and then add 700kg Weathered coal, stirred and heated to 80°C, reacted for 4 hours, the resulting liquid with a concentration of 28% was pumped to the spray drying tower for atomization and drying to obtain spherical fine particles of high-efficiency temperature-resistant fluid loss reducer, the first time The recommended dosage is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com