Flame-retardant compound adhesive tape and manufacturing method thereof

A technology of composite adhesive tape and production method, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as low melting temperature, carcinogenic hydrogen chloride, and impact on human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The physical properties of polyurethane thermoplastic elastomer TPU (Thermoplastic Polyurethane) are between plastic materials and rubber materials, and various types of products have been manufactured through continuous research and development and different processes. TPU The nature of the product has been greatly improved and improved with the scope of use and product needs, such as mechanical strength, abrasion resistance, cold resistance, and biocompatibility, etc.; and the scope of application tends to be diversified, such as people’s livelihood, defense industry and medical Sanitary products and other uses.

[0026] If polyvinyl chloride (PVC) is blended with TPU, not only can it effectively reduce the overall chlorine content, but also because of its elasticity, it can replace the function of a plasticizer. The present invention utilizes this technology to produce flame-resistant composite tape.

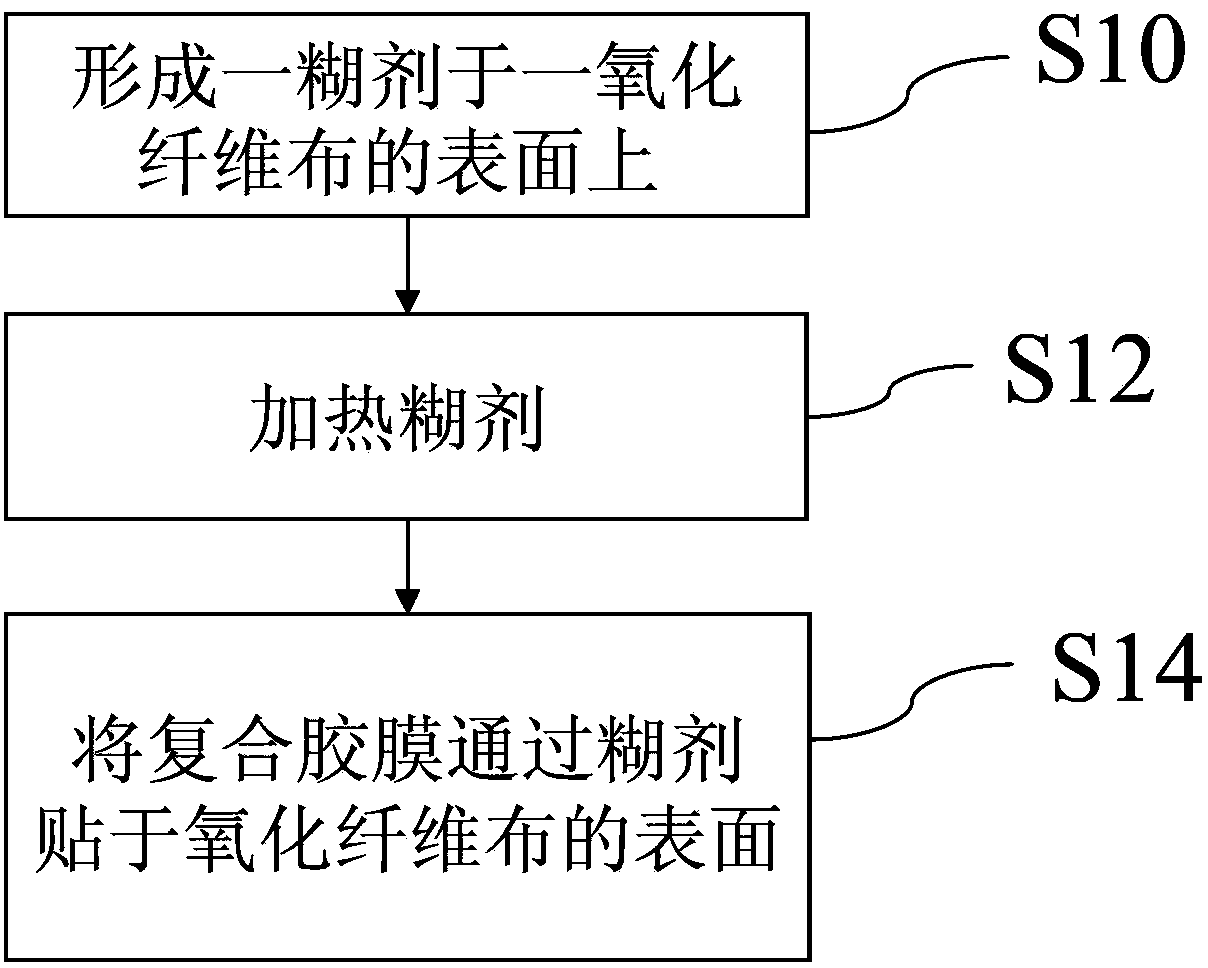

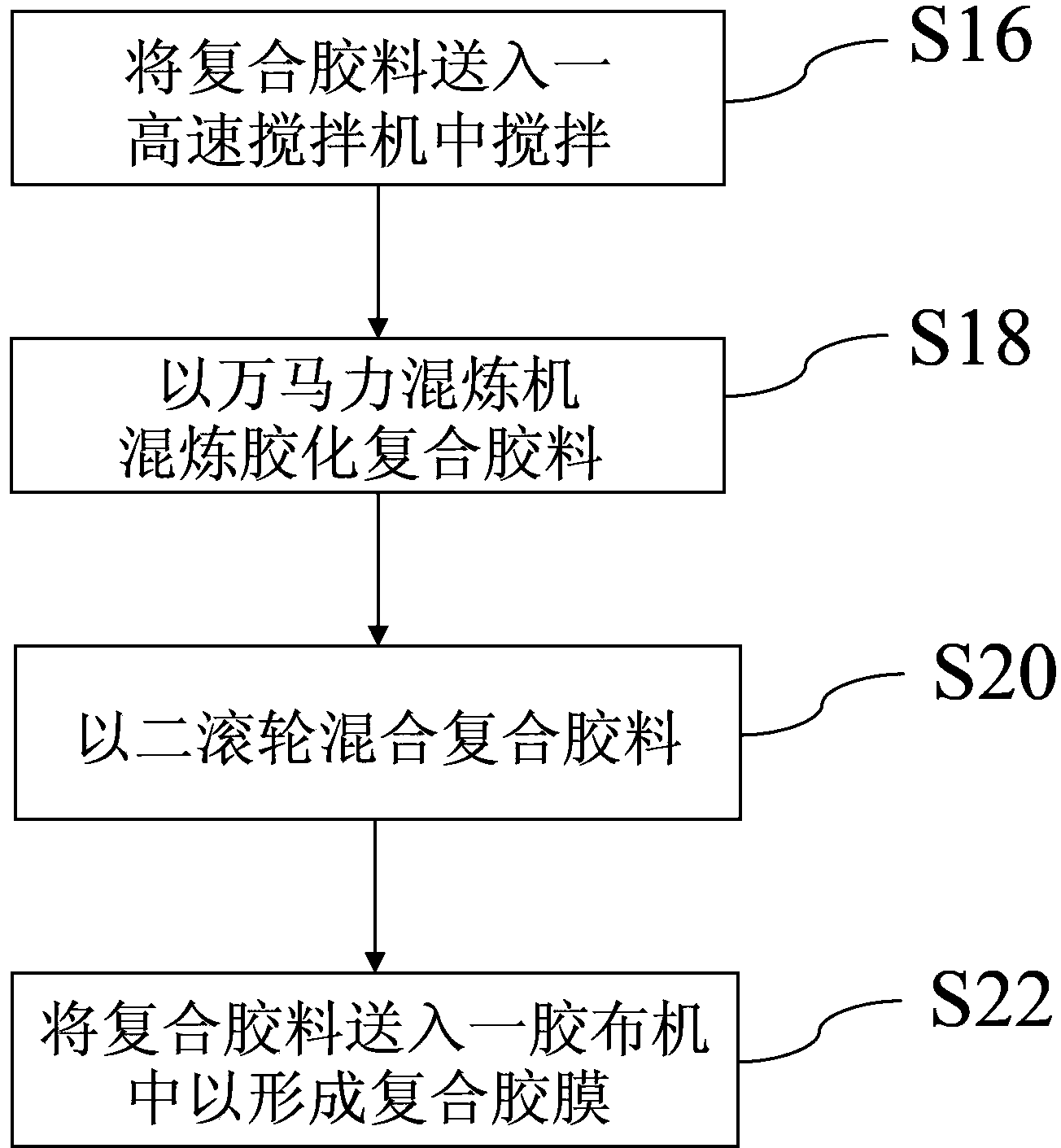

[0027] Such as figure 1 As shown, the present invention includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com