Fully biodegradable polyester material, and preparation method and application thereof

A technology of biodegradable polyester and polyester, applied in the field of biodegradable polyester materials, can solve the problems of high cost, achieve the effect of promoting melting, ensuring the mechanical properties of film materials, and excellent blown film processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Preparation of fully biodegradable polyester material

[0051] Weigh each component (%) according to the following weight percentage:

[0052]

[0053] The preparation process is as follows:

[0054] Put PBSA in an oven, dehumidify and dry at 50-80°C for 8 hours, and control the moisture content below 300ppm;

[0055] Put the dried mixture and additives into the high-speed mixer according to the ratio and mix at high speed for 30s;

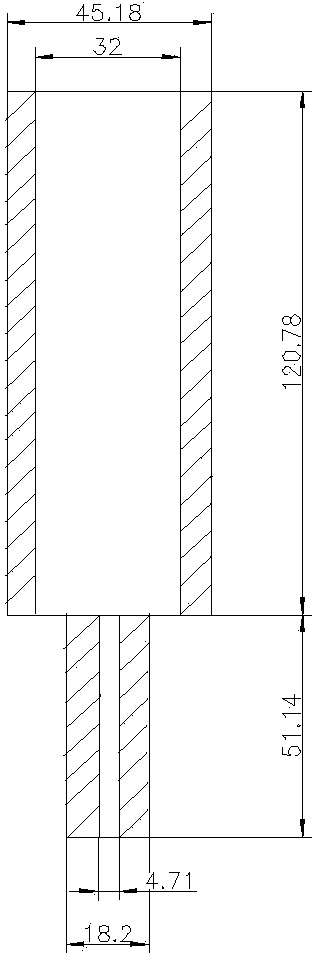

[0056] Use a metering scale to accurately meter and feed the extruder; the nozzle design see figure 1 .

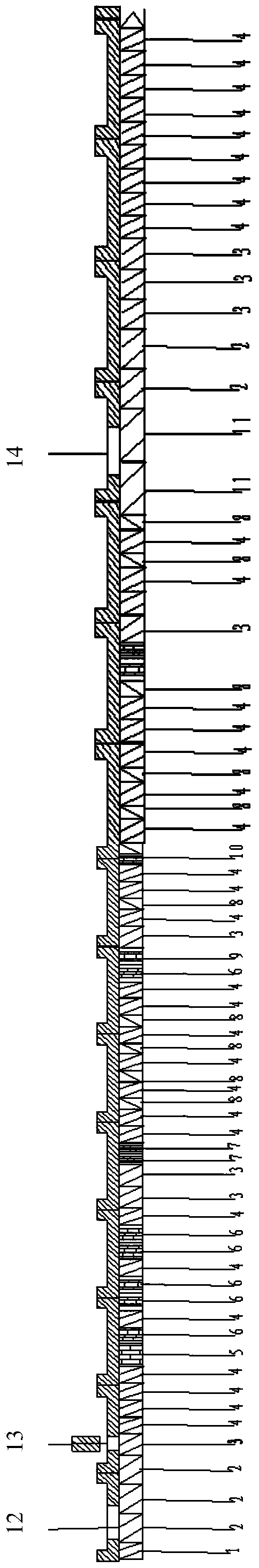

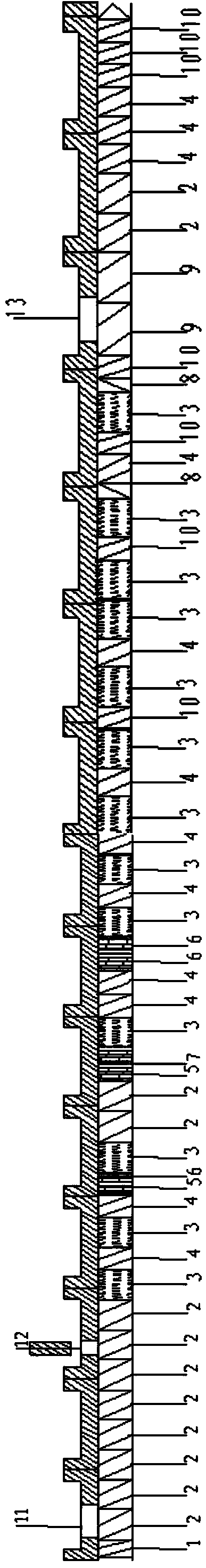

[0057] The length-to-diameter ratio of the extruder is 60:1;

[0058] Extruder power and model: 65D model, co-rotating parallel twin-screw extruder;

[0059] The mixing temperature is as follows: 90-100°C for the first stage; 120-140°C for the second stage; 190-200°C for the third stage; 210-220°C for the fourth stage; 220°C; eight sections 210-220°C; nine sections 210-220°C; ten sections 210-220°C; eleven sectio...

Embodiment 2

[0076] Embodiment 2: Using the screw used in Example 1, adjust the amount of PBSA to prepare a fully biodegradable polyester material

[0077] Weigh each component (%) according to the following weight percentage:

[0078]

[0079] The preparation process is as follows:

[0080] Put PBSA in an oven, dehumidify and dry at 50-80°C for 8 hours, and control the moisture content below 300ppm;

[0081] Put the dried mixture and additives into the high-speed mixer according to the ratio and mix at high speed for 30s;

[0082] Use a weighing scale to accurately measure and feed the extruder;

[0083] The length-to-diameter ratio of the extruder is 60:1;

[0084] Extruder power and model: 65D model, co-rotating parallel twin-screw extruder;

[0085] The mixing temperature is as follows: 90-100°C for the first stage; 120-140°C for the second stage; 190-200°C for the third stage; 210-220°C for the fourth stage; 220°C; eight sections 210-220°C; nine sections 210-220°C; ten section...

Embodiment 3

[0102] Embodiment 3: Using the screw used in Example 1, adjust the amount of PBSA to prepare a fully biodegradable polyester material

[0103] Weigh each component (%) according to the following weight percentage:

[0104] Genuine PBSA 99.5

[0105] Toluene diisocyanate 0.5

[0106] The preparation process is as follows:

[0107] Put PBSA in an oven, dehumidify and dry at 50-80°C for 8 hours, and control the moisture content below 300ppm;

[0108] Put the dried mixture and additives into the high-speed mixer according to the ratio and mix at high speed for 30s;

[0109] Use a weighing scale to accurately measure and feed the extruder;

[0110] The length-to-diameter ratio of the extruder is 60:1;

[0111] Extruder power and model: 65D model, co-rotating parallel twin-screw extruder;

[0112] The mixing temperature is as follows: 90-100°C for the first stage; 120-140°C for the second stage; 190-200°C for the third stage; 210-220°C for the fourth stage; 220°C; eight secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com