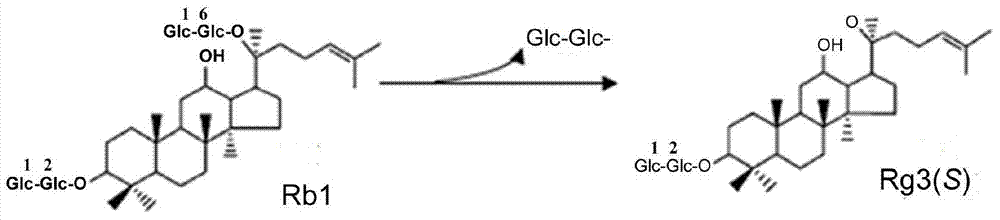

A rapid non-thermal preparation method of rare ginsenoside rg3(s)

A ginsenoside, non-thermal technology, applied in the field of rapid non-thermal preparation of rare ginsenoside Rg3, which can solve the problems of complex enzyme preparation steps, long cultivation period, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The method for degrading ginsenoside Rb1 to generate ginsenoside Rg3(S) in the present invention is to dissolve the ginsenoside Rb1 sample in 1% hydrochloric acid solution, prepare a solution with a concentration of 1mM ginsenoside Rb1, and directly pass it into a high-voltage pulsed electric field at normal temperature Treat, its electric field intensity is 20kV / cm, and pulse number is 10; Water saturated n-butanol extraction reaction liquid, centrifugation, supernatant liquor volatilizes and removes solvent, and the yield of ginsenoside Rg3 (S) is analyzed by high performance liquid chromatography It was 68.58%.

Embodiment 2

[0017] The method for degrading ginsenoside Rb1 to generate ginsenoside Rg3(S) in the present invention is to dissolve the ginsenoside Rb1 sample in a 1.5% hydrochloric acid solution, prepare a 1mM ginsenoside Rb1 solution, and directly pass it into a high-voltage pulsed electric field at room temperature To process, its electric field strength is 25kV / cm, and the number of pulses is 10; water-saturated n-butanol extracts the reaction solution, centrifuges, the supernatant is volatilized to remove the solvent, and the yield of ginsenoside Rg3 (S) is analyzed by high performance liquid chromatography It was 63.28%.

Embodiment 3

[0019] The method for degrading ginsenoside Rb1 to generate ginsenoside Rg3(S) in the present invention is to dissolve the ginsenoside Rb1 sample in a 1.5% hydrochloric acid solution, prepare a 1mM ginsenoside Rb1 solution, and directly pass it into a high-voltage pulsed electric field at room temperature To process, its electric field intensity is 20kV / cm, and the number of pulses is 8; the reaction solution is extracted with water-saturated n-butanol, centrifuged, the supernatant is volatilized to remove the solvent, and the yield of ginsenoside Rg3(S) is analyzed by high performance liquid chromatography It was 54.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com