Steel flattening unit production line structure

A production line and leveling machine technology, applied in other manufacturing equipment/tools, metal processing, metal processing equipment, etc., can solve problems such as low production efficiency, and achieve the effect of reducing labor intensity and high shearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

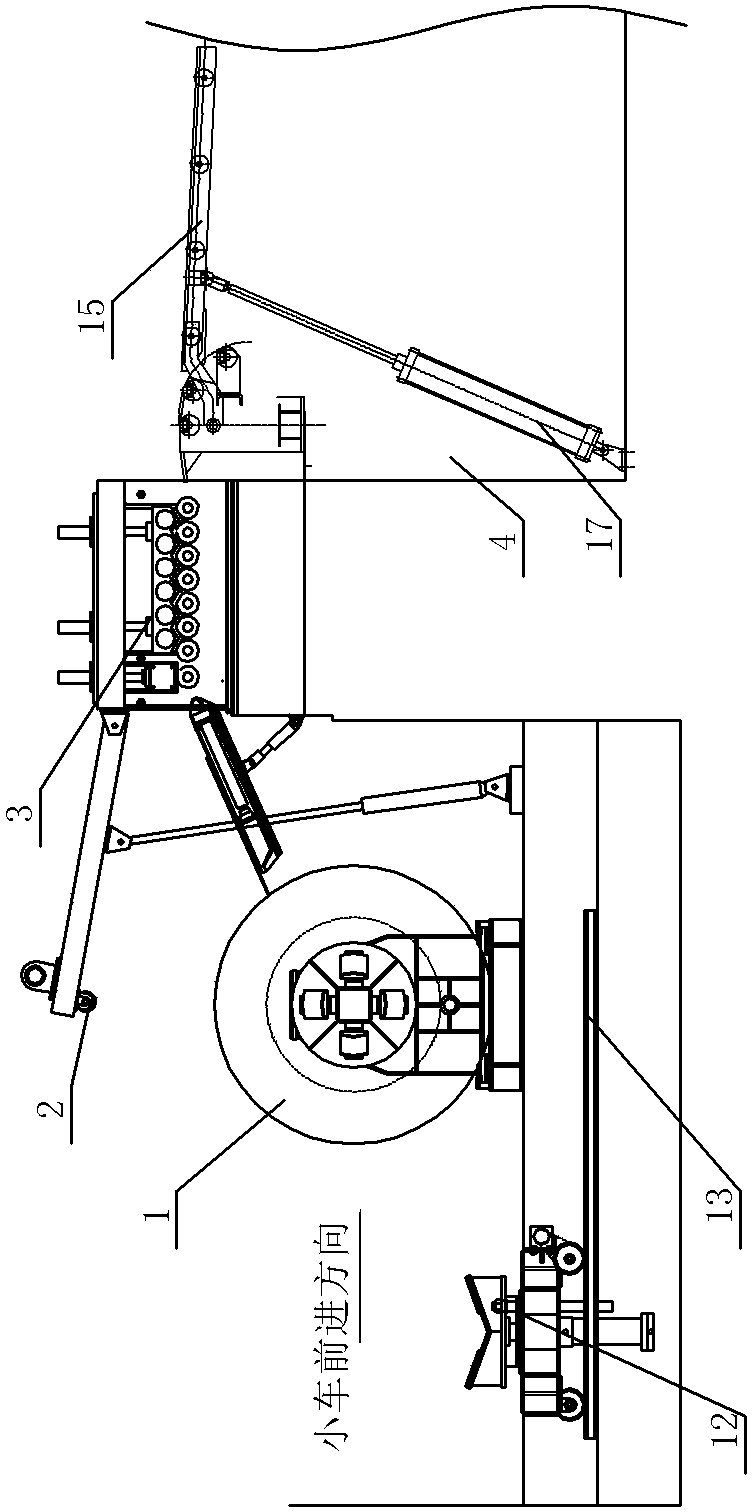

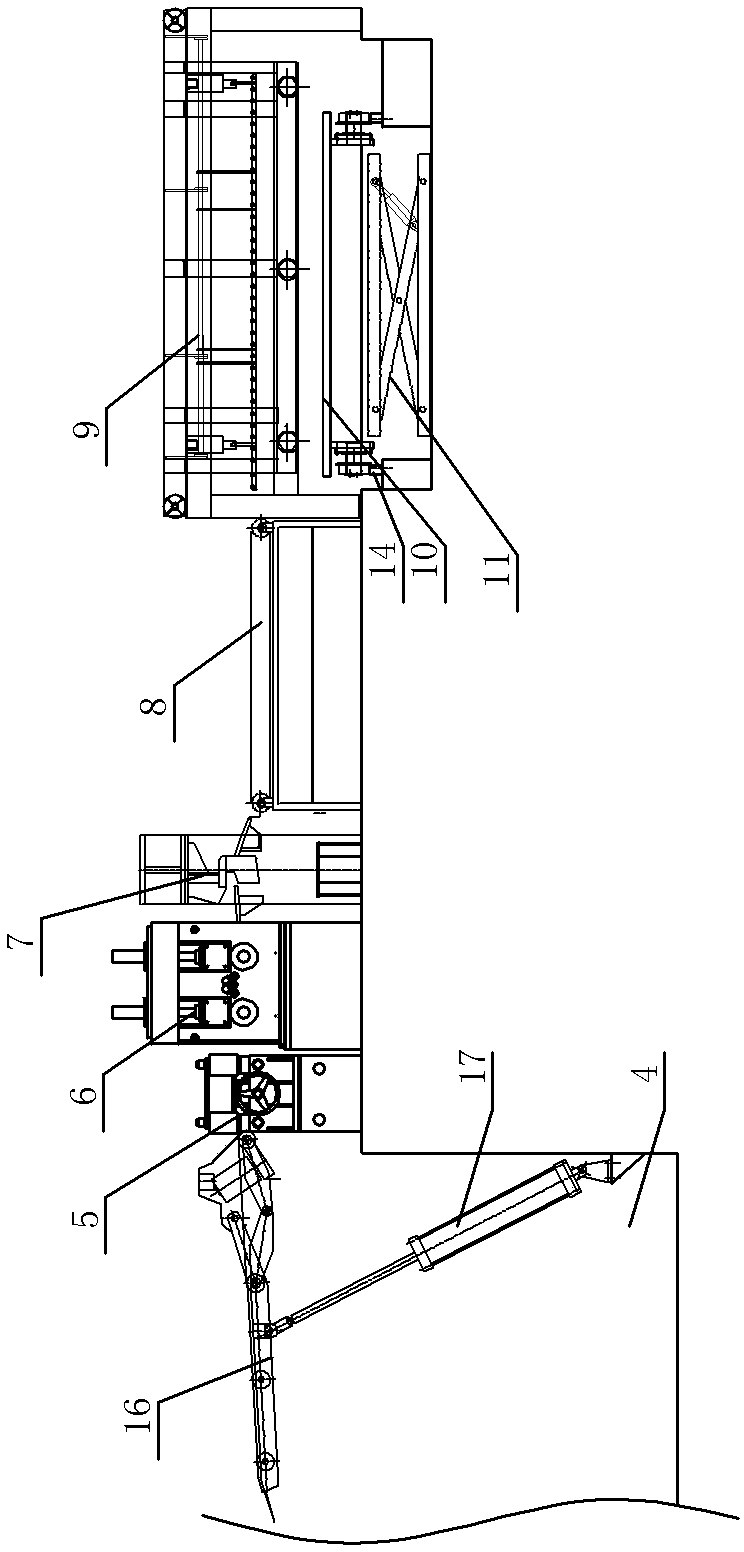

[0008] A kind of production line structure of steel leveling unit, see figure 1 , figure 2 : It includes an uncoiler 1, a material guiding mechanism 2 is arranged above the uncoiler 1, a leveler 3 is arranged behind the uncoiler 1, a looper storage chamber 4 is arranged behind the leveler 3, and a looper storage chamber 4 is arranged behind the output end of the guide centering roller 5, and the rear of the guide centering roller 5 is arranged with a servo sizing machine 6, and the output end of the servo sizing machine 6 is provided with a high-speed shearing machine 7, and the high-speed shearing machine 7 The rear leads to the inlet side of the conveyor 8, and the outlet side of the conveyor 8 leads to the collecting frame 9, and the outlet below the collecting frame 9 is provided with a discharge flatbed car 10, and the discharge flatbed cart 10 is supported in the track 14, and the track 14 Lifting platforms 11 are respectively arranged on both sides. When the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com