Filter housing with integrally threaded port

A filter shell and filter technology, applied in cartridge filters, filter separation, filter circuits, etc., can solve problems such as fluid leakage and achieve the effect of enhancing structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

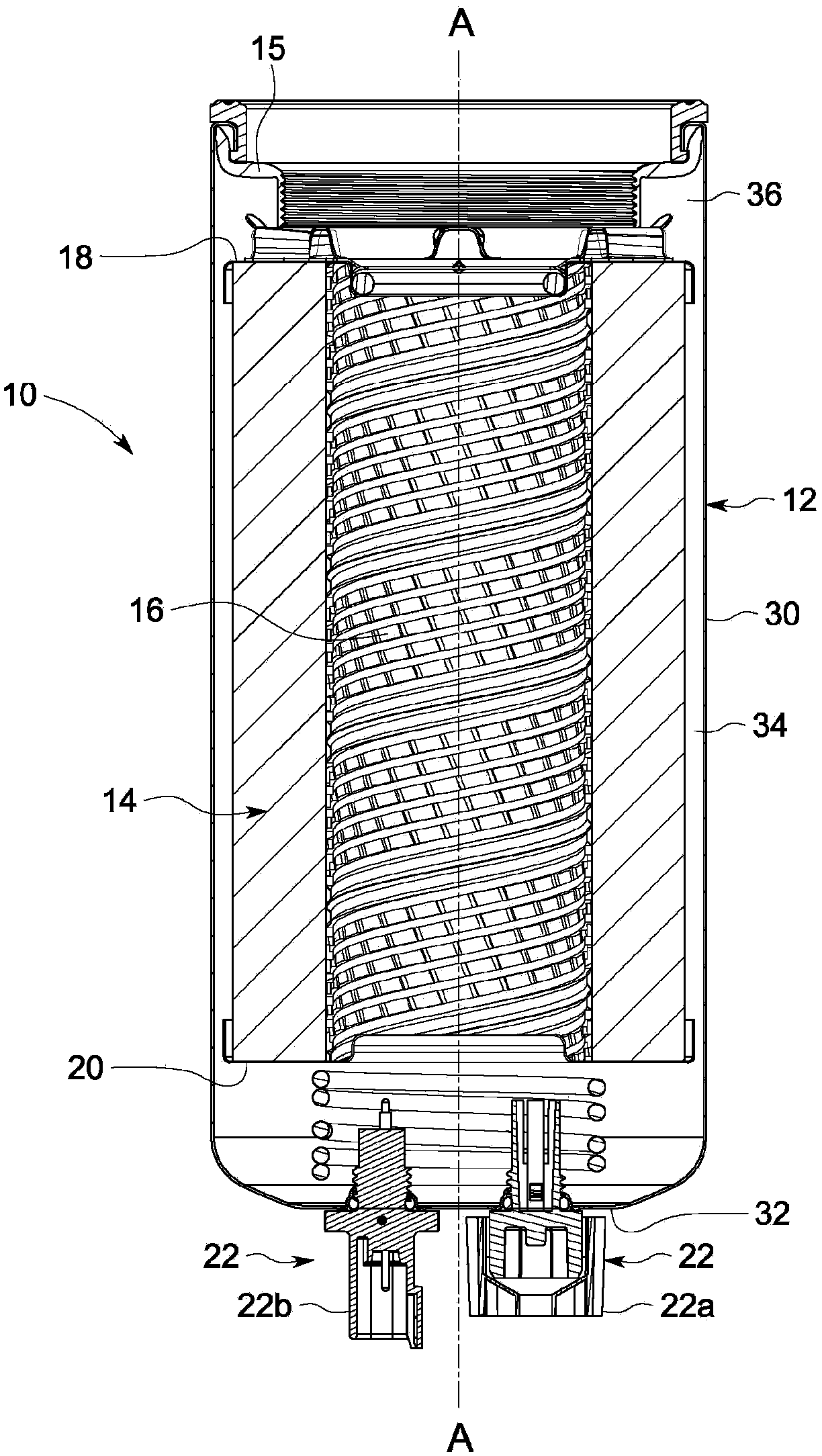

[0018] refer to figure 1 , the illustrated filter assembly 10 includes a filter housing 12, filter media 14 disposed within the filter housing, and a nut plate 15 attached to the open end of the filter housing. figure 1 The filter assembly 10 illustrated in is configured as a fuel filter assembly for filtering diesel fuel. However, filter assembly 10 may be configured for any desired filtration application. Examples of other filtration applications include, but are not limited to, petroleum filter assemblies for filtering petroleum, hydraulic filter assemblies for filtering hydraulic fluid, and other applications.

[0019] also, figure 1 The filter assembly 10 illustrated in is configured for single use. However, in other embodiments, the filter assembly may be configured to allow replacement of the filter media 14, in which case the housing 12 may be reused, and a removable cover may be attached to the filter housing. end (rather than the nut plate 15) to allow access to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com