Potato chips drying machine

A drying machine and potato chip technology, applied in the direction of drying and preserving seeds, can solve the problems of insufficient drying in assembly line processing, poor sanitation conditions, and high labor costs for natural drying, and achieve simple structure, low processing cost, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

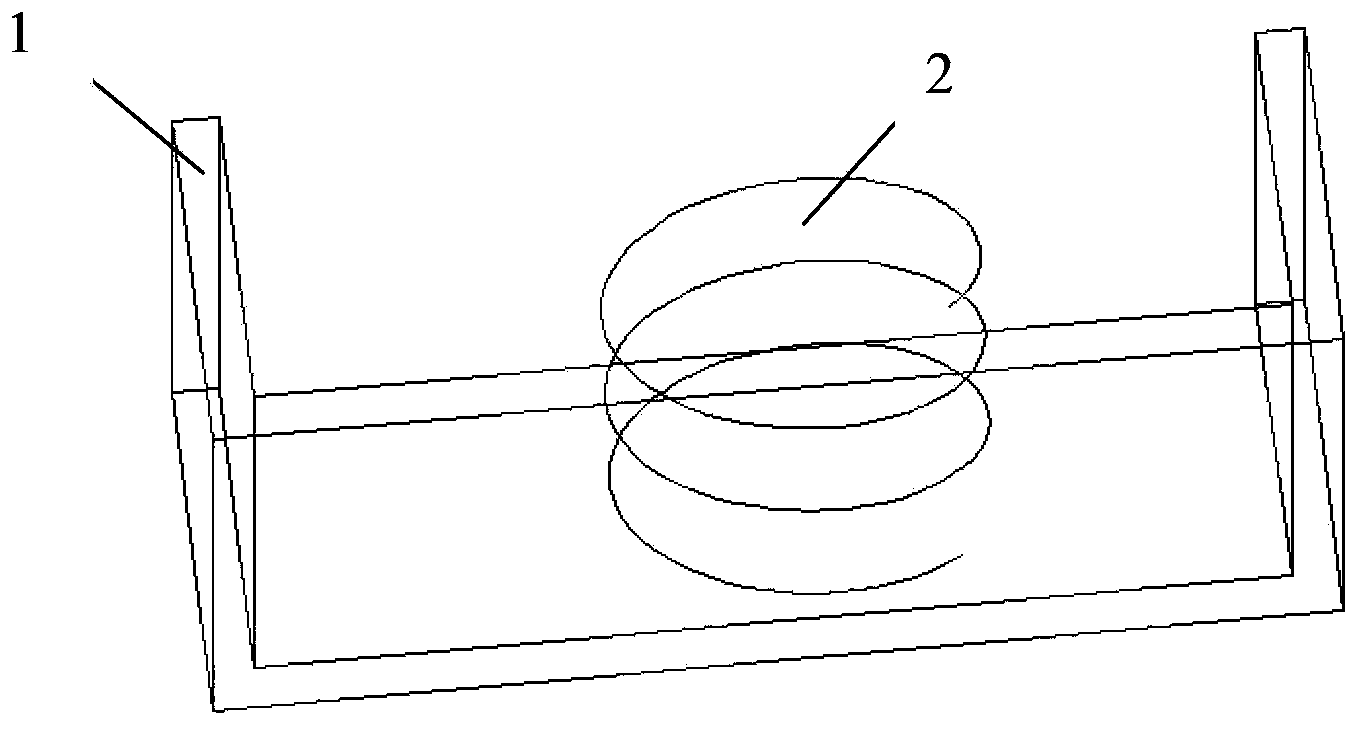

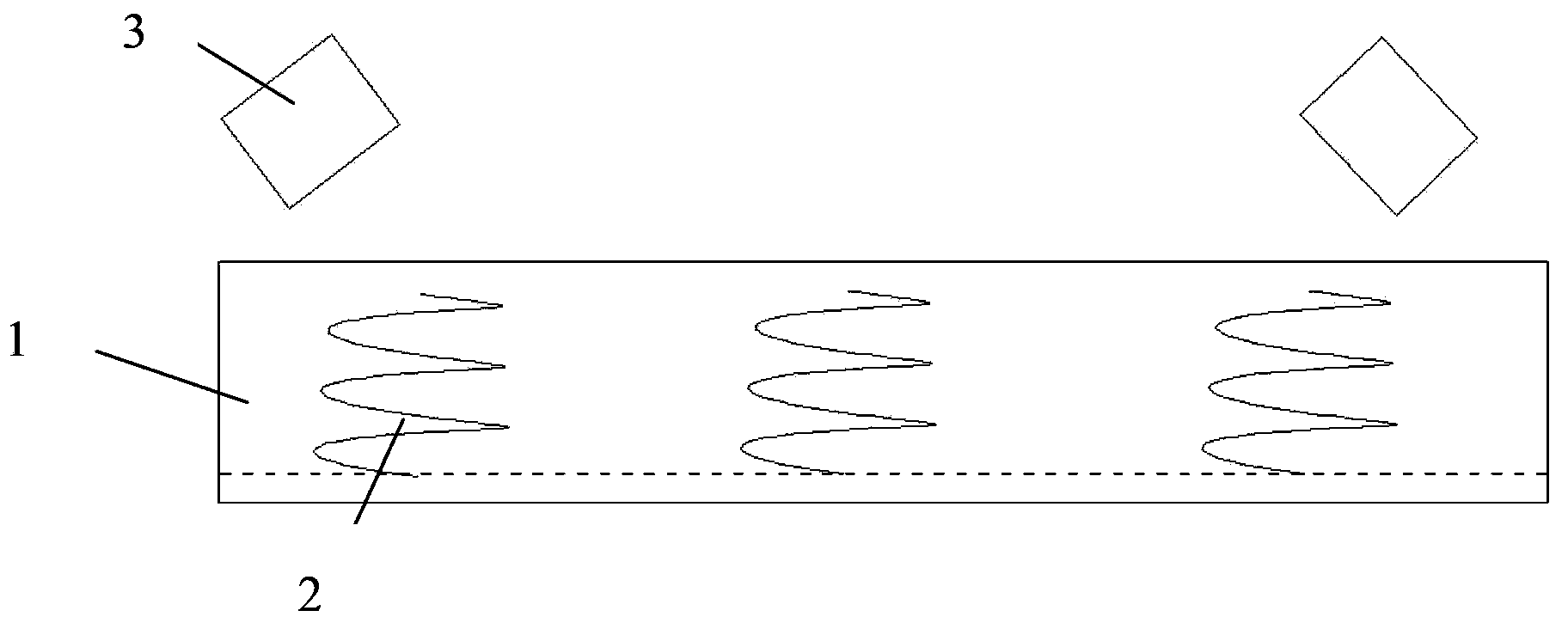

[0013] like figure 1 As shown, a kind of potato chips dryer provided by the present invention includes a conveyor belt 1, a blowing port 2 and a stirring shaft 3, the blowing port 2 is arranged on the conveyor belt 1, and the stirring shaft 3 is helical and has a gas inside. The hollow part has small holes evenly distributed therein, and the stirring shafts 3 are equidistantly distributed on the conveyor belt.

[0014] The rotation directions of adjacently distributed stirring shafts 3 are opposite.

[0015] The gas temperature is not lower than 30 degrees Celsius

[0016] The working process of this example: when the potato chips are output on the conveyor belt 1 of the drying equipment, the top is dried by the wind blown out from the air outlet 2 . At the same time, the potato chips are stirred by a spiral stirring shaft 3 arranged on the conveyor belt every time. The stirring process makes the gathered potato chips produce more gaps, and the wind blown from the small hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com