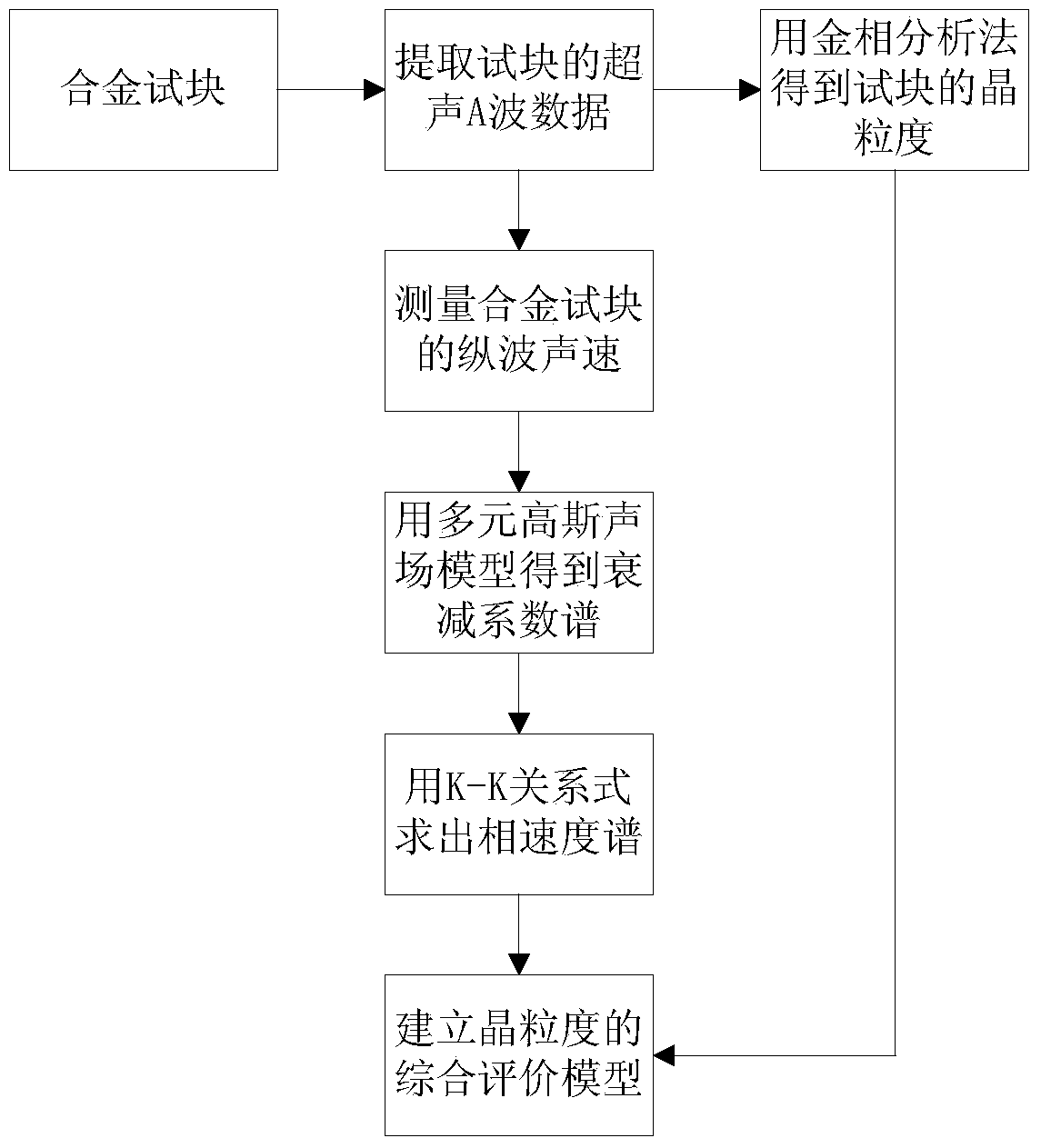

High-temperature alloy grain size evaluation method based on ultrasonic phase velocity

A technology for superalloys and evaluation methods, which is applied in the analysis of solids by using sonic/ultrasonic/infrasonic waves, which can solve the problems of acoustic wave attenuation, difficulty in distinguishing the bottom wave front from noise signals, and the decline in evaluation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

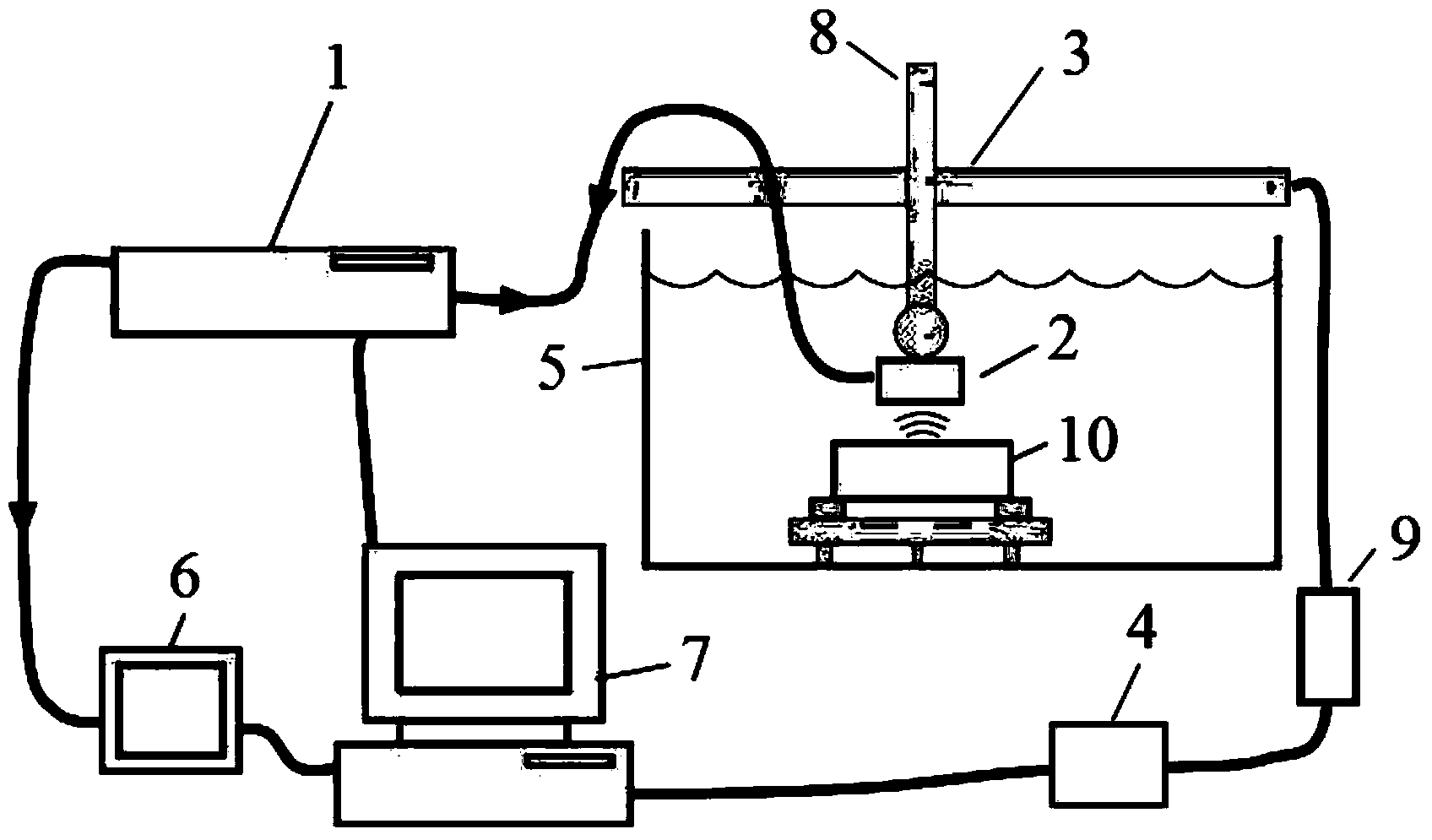

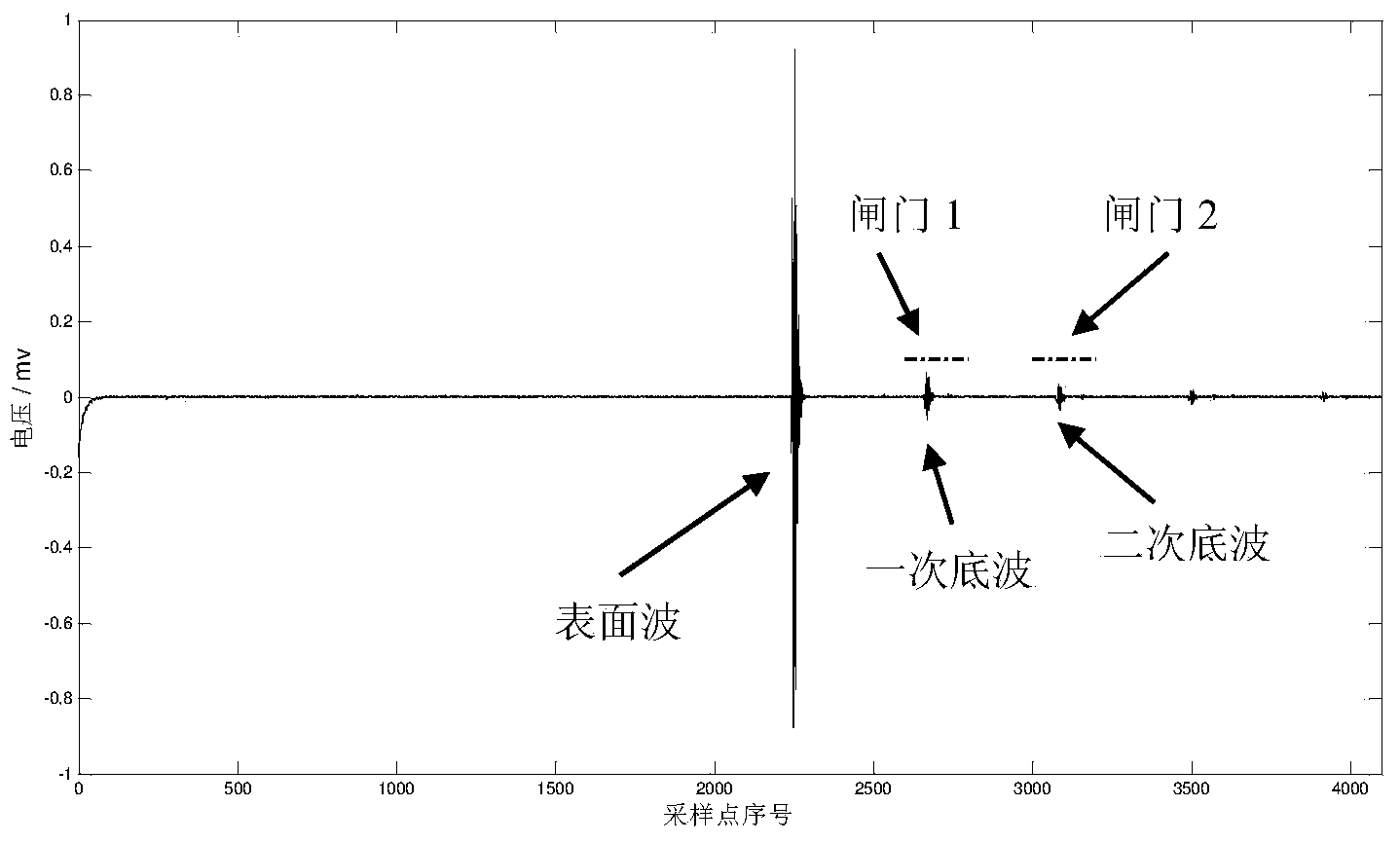

[0047] see Figure 2-Figure 12 , this specific embodiment takes a batch of high-temperature alloys with the grade In718 as an example to illustrate the evaluation method of the present invention. In the present invention, the object to be detected is firstly fixed in a tank filled with water, and the ultrasonic pulse generator / receiver (also known as ultrasonic instrument) is used to excite the ultrasonic longitudinal wave probe, and the ultrasonic longitudinal wave probe is clamped on the six-degree-of-freedom motion platform through the probe frame. The motion control card installed on the computer is connected to the control circuit to control the movement of the six-degree-of-freedom motion platform, adjust the posture of the ultrasonic probe in the tank, and use the high-speed data acquisition card on the computer to acquire and store the ultrasonic signals received by the ultrasonic instrument. Finally, further analysis and processing are carried out on the computer. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com