Nanocrystalline-amorphous high-capacity hydrogen storage electrode alloy and preparation method thereof

An electrode alloy and nanocrystalline technology, which is applied in the field of hydrogen storage alloy materials, can solve the problems of poor cycle stability of Ni-type hydrogen storage alloys, long-term preparation of amorphous, and difficulty in mass production, etc., to achieve electrochemical hydrogen storage at room temperature The effect of improved capacity, reduced thermal stability, and good low-temperature hydrogen absorption and desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the chemical formula (Mg 23.5 Zr 0.5 Ni 10 co 2 ) 0.9 Nd 0.1 , choose bulk metal magnesium, metal zirconium, metal nickel, metal cobalt and metal neodymium as raw materials, and the purity of all metals is ≥99.5%. The crucible capacity of the melting furnace is about 2kg, and the ingredients are calculated as 2kg per furnace. Weigh 922.4g of metal magnesium, 68.2g of metal zirconium, 877.6g of metal nickel, 176.2g of metal cobalt, and 25.2g of metal neodymium according to the chemical dosage ratio, and place them in the magnesia crucible of the intermediate frequency induction furnace, then cover the furnace cover and vacuumize About 40min to vacuum 5×10 -3 Above Pa, refill helium until the gas pressure reaches 0.04MPa, adjust the power to 4.5 kW, control the temperature at 650°C to melt magnesium metal, then adjust the power to 25 kW, control the temperature at 1600°C to melt other metals. After all the metals are melted, keep it under the melting c...

Embodiment 2

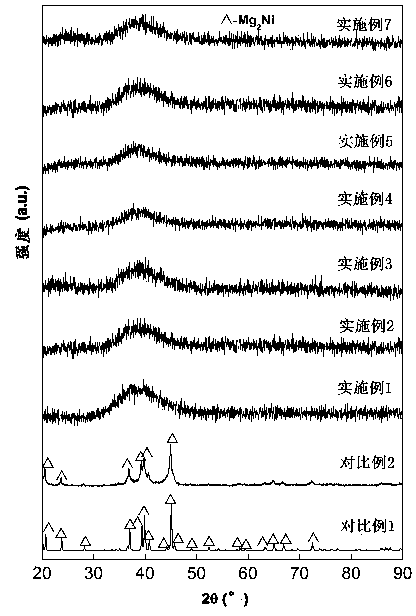

[0034] The composition of the alloy is: (Mg 23.5Zr 0.5 Ni 10 co 2 ) 0.8 Nd 0.2 Take by weighing metal magnesium 908.8g, metal zirconium 67.2g, metal nickel 864.6g by stoichiometric ratio, metal cobalt 173.6g, metal neodymium 55.8g, prepare alloy according to the method for example 1, difference is that the quenching speed of adopting is 10 m / s. The XRD test results show that the alloy has a nanocrystalline-amorphous structure, and the results are shown in figure 1 ; The electrochemical capacity and cycle stability of the alloy were tested with a program-controlled analog battery tester, and the results are shown in Table 1.

Embodiment 3

[0036] The composition of the alloy is (Mg 23.5 Zr 0.5 Ni 10 co 2 ) 0.95 Nd 0.05 Take by weighing metal magnesium 1008.7g, metal zirconium 74.6g, metal nickel 959.7g by stoichiometric ratio, metal cobalt 192.7g, metal neodymium 13.0g, prepare alloy according to the method for example 1, XRD test result shows that alloy has nanocrystal-non- crystal structure, see figure 1 ; The electrochemical capacity and cycle stability of the alloy were tested with a program-controlled analog battery tester, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com