Built-in disc fibrous bed reactor for fermenting production of butyric acid

A reactor and fiber bed technology is applied in the field of built-in disc fiber bed reactors, which can solve the problems of small immobilization area of cotton fibers, low utilization rate of fermentation equipment, and high probability of bacterial contamination, so as to solve the difficulties of disinfection and sterilization, The effect of low immobilization cost and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 produces the method for butyric acid

[0039] Butyric acid was produced in 100 mL anaerobic serum bottles using Clostridium tyrobutyricum ATCC25755. Both the seed and fermentation medium formulations are: 30g / L glucose, 5g / L yeast extract (BBI), 5g / L peptone (BBI), 6g / L NaCl, 3g / L (NH 4 ) 2 · SO 4 , 1.5g / L K 2 HPO 4 , 0.6g / L MgSO 4 ·7H 2 O, 0.03g / LFeSO 4 ·7H 2 O, 0.3g / L cysteine-HCl, 0.05mL resazurin indicator solution (1g / L), boiled in a boiling water bath to remove oxygen, carbon source and nitrogen source were sterilized separately, pH6.0.

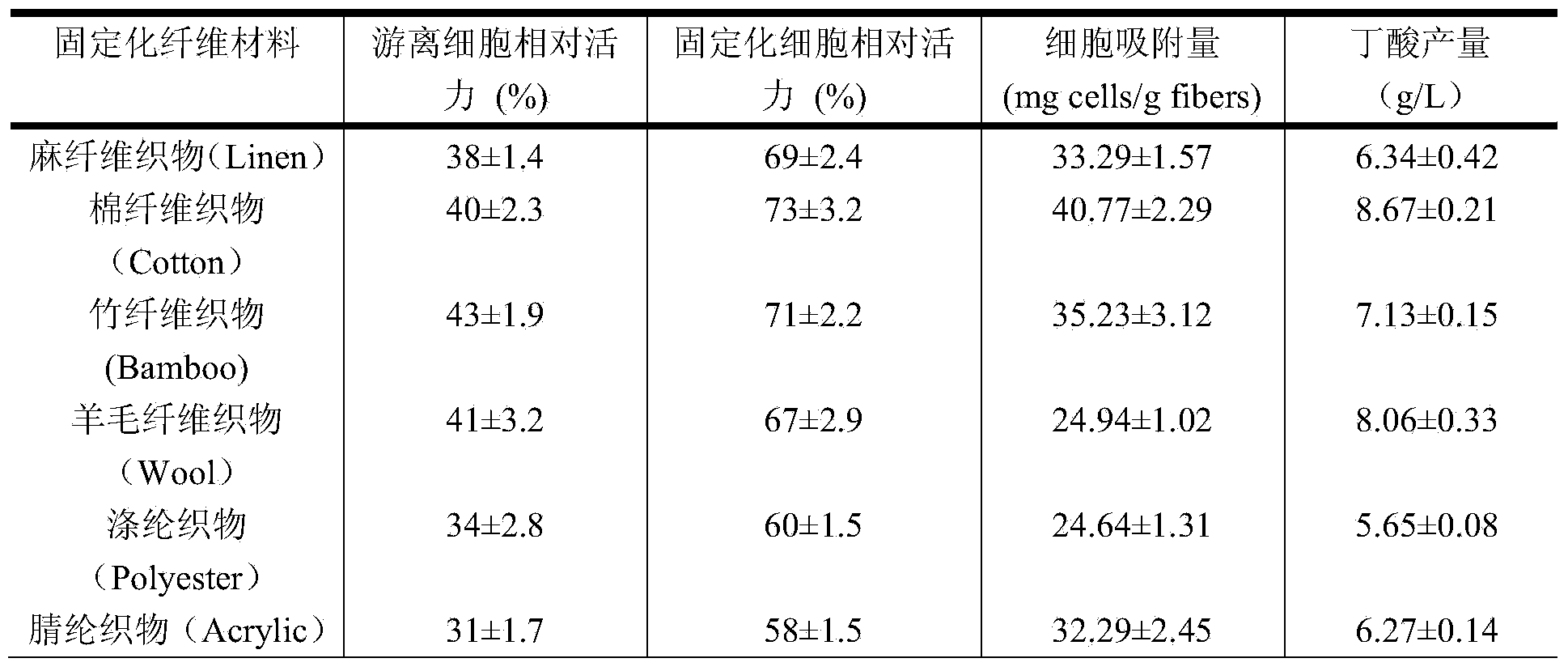

[0040] Put 3ml Clostridium tyrobutyricum seed solution into 60ml fermentation medium and different immobilized fiber materials cut into 2mm*2Mm size (hemp fiber fabric, cotton fiber fabric, bamboo fiber fabric, wool fiber fabric, synthetic fiber such as polyester fabric, acrylic fabric) in anaerobic serum bottles (total volume: 100ml, initial pH: 6.0), cultured at 37°C until the end of fermentation, see Tab...

Embodiment 2

[0044] Embodiment 2 produces the method for butyric acid

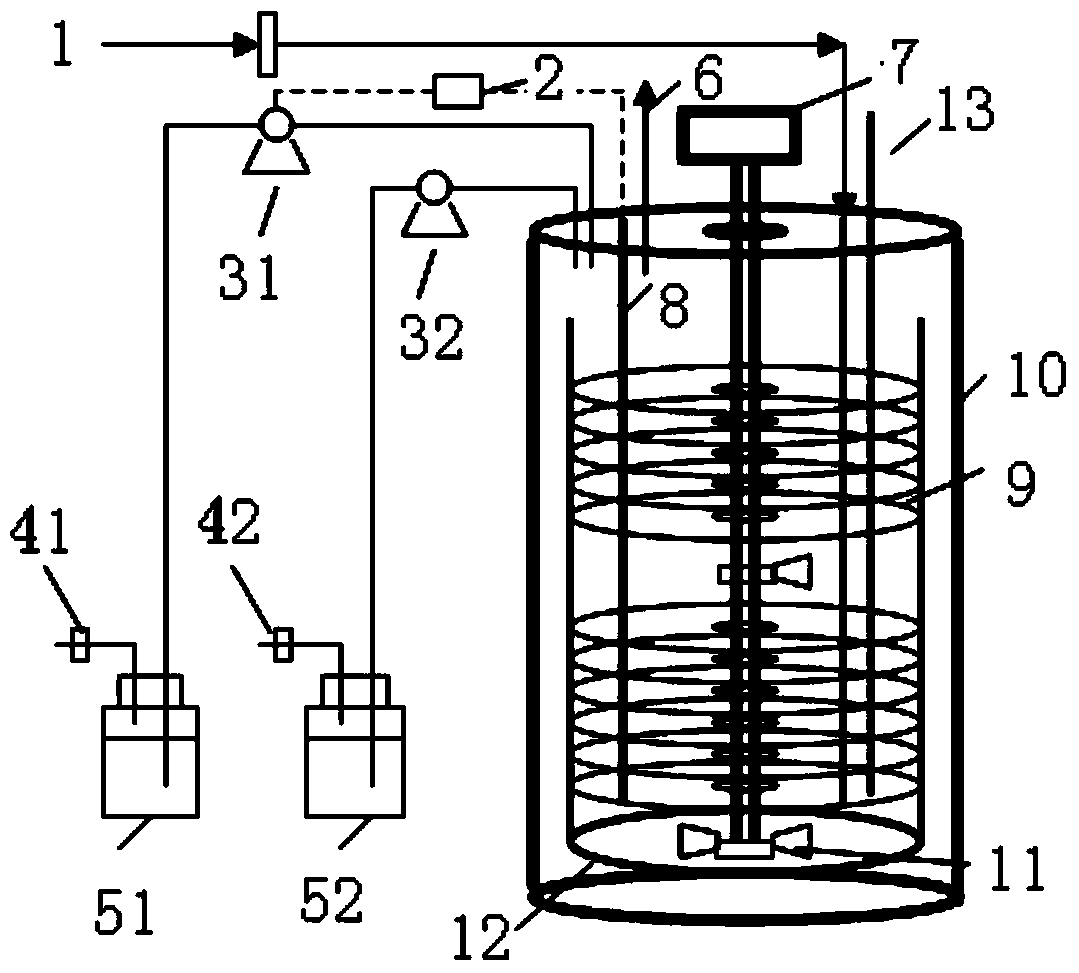

[0045] Clostridium tyrobutyricum (Clostridium tyrobutyricum ATCC25755) was used to produce butyric acid in a built-in dish fiber bed reactor.

[0046] Seed medium: 30g / L glucose, 5g / L yeast extract (BBI), 5g / L peptone (BBI), 6g / L NaCl, 3g / L (NH 4 ) 2 · SO 4 , 1.5g / L K 2 HPO 4 , 0.6g / LMgSO 4 ·7H 2 O, 0.03g / L FeSO 4 ·7H 2 O, 0.3g / L cysteine-HCl, 0.05mL resazurin indicator solution (1g / L), boiled in a boiling water bath to remove oxygen, carbon source and nitrogen source were sterilized separately, pH6.0.

[0047] Fermentation medium: 60g / L glucose, 5g / L yeast extract (BBI), 5g / L peptone (BBI), 6g / L NaCl, 3g / L (NH 4 ) 2 · SO 4 , 1.5g / L K 2 HPO 4 , 0.6g / LMgSO 4 ·7H 2 O, 0.03g / L FeSO 4 ·7H 2 O, carbon source and nitrogen source are sterilized separately, pH 6.0.

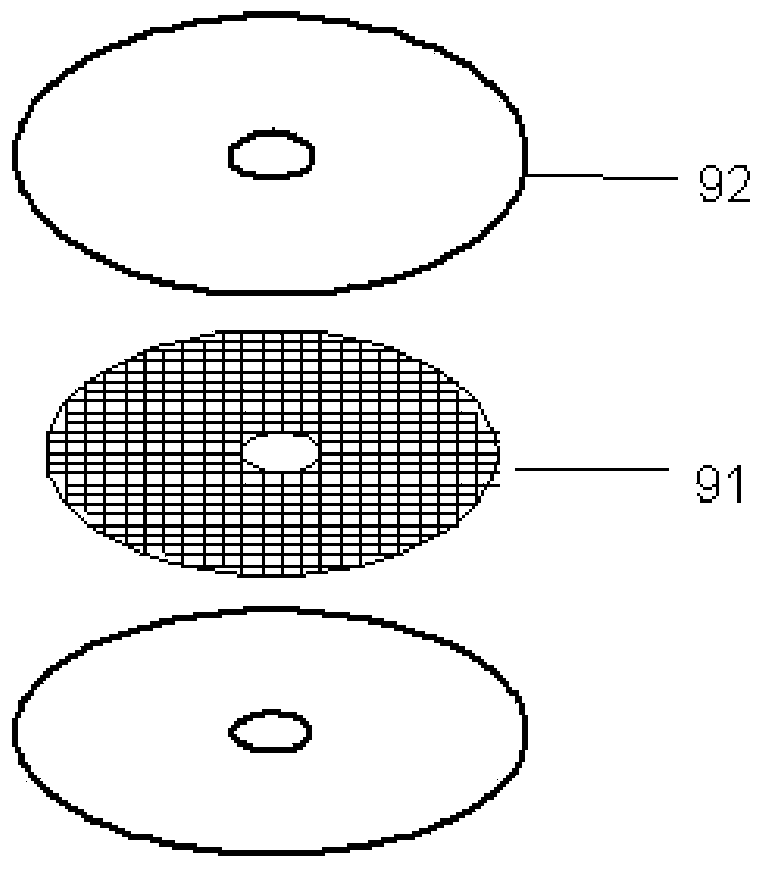

[0048] Fix the composite disc-shaped fiber structure of different sizes in the reactor body, insert 150ml Clostridium tyrobutyricum seed liquid ...

Embodiment 3

[0052] Embodiment 3 produces the method for butyric acid

[0053] Clostridium tyrobutyricum (Clostridium tyrobutyricum ATCC25755) was used to produce butyric acid in a built-in dish fiber bed reactor.

[0054] Wherein seed culture medium and fermentation medium are identical with embodiment 2.

[0055] Different numbers of composite disc fiber structures (diameter ratio of 0.8) were fixed in the reactor body, and 150ml Clostridium tyrobutyricum seed liquid was inserted into the reactor body containing 3L seed medium (total volume: 5L ), the temperature is 37°C, and N 2 Maintain the anaerobic state of the tank, stir with a stirring device (speed 160r / min), and at the same time use the first constant flow pump to add 8mol / L sodium hydroxide solution to control the pH of the seed liquid in the reactor body to 6.0, and cultivate for 30 hours to achieve Cells are immobilized on composite discs. Replace the seed solution in the reactor body with the fermentation medium, keep the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com