Fire retardation fireproof material and preparation method thereof

A technology of refractory materials and refractory fillers is applied in the field of refractory materials, which can solve the problems of unsatisfactory, expensive, and inconvenient in the production and processing of magnesium oxide mineral fireproof insulated cables.

Active Publication Date: 2014-03-19

东莞市朗晟材料科技有限公司

View PDF1 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Magnesia mineral fire-resistant insulated cables have the following disadvantages in the manufacture and application: First, the production and processing of magnesium oxide mineral fire-resistant insulated cables cannot be processed as conveniently as polymer materials, and magnesium oxide mineral refractory insulated cables require special production and processing equipment. Expensive, high equipment cost; second, because the outer sheath of the magnesia mineral refractory insulated cable is all copper, the price of copper is high, making the production cost higher, which is limited to a certain extent in practical application; third , due to the special requirements in the production, processing, transportation, laying, installation and use of copper-sheathed magnesium oxide mineral fire-resistant insulated cables, making its laying and installation more cumbersome and complicated, resulting in an increase in the cost of raw materials, it is difficult to large-scale Popular application, especially in civil buildings, has not been widely used so far

At present, there are almost no gaps in the national fire-proof A-level organic materials, all of which are occupied by inorganic materials, and because of the defects of inorganic materials, they have not been able to meet the requirements of the Ministry of Public Security.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

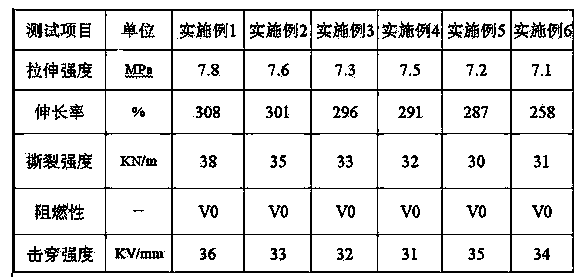

The present invention relates to a fire retardation fireproof material and a preparation method thereof. The fire retardation fireproof material comprises, by mass, 100 parts of a silicon rubber, 5-30 parts of an organic siloxane, 1-10 parts of zinc oxide, 20-200 parts of a fireproof filler, and 20-200 parts of white carbon black. According to the present invention, the processed product has good mechanical property (such as tensile strength, elongation, and tearing strength), good fire retardation and good electrical property (such as breakdown strength), burns at a certain temperature or under an aerobic condition, and can form a rigid housing, wherein the housing can form a compact fireproof layer at a temperature of more than 600 DEG C; fire retardation, temperature resistance and fire resistance of the material can be substantially improved in the case of addition of zinc oxide; the addition amounts of the fireproof filler and the white carbon black can be substantially improved; and the cost of the fire retardation material can be substantially reduced under the premise of assurance of good tensile strength, tear strength, breakdown strength, and fire resistance.

Description

technical field [0001] The invention relates to the technology in the field of refractory materials, and in particular provides a flame-retardant refractory material and a preparation method. Background technique [0002] Usually, silicone rubber itself is not flame retardant or fire-resistant. In a fire accident, wires and cables are not fire-resistant and easy to burn in case of fire. This field lacks a fire-resistant silicone rubber. It is required not only to have the excellent characteristics of rubber during normal use, It also has good flame retardancy and fire resistance. The products made by using it can play a certain protective role in the fire, and can reduce the loss and harm caused to people in the fire. [0003] At present, most fire-resistant and flame-retardant cables use magnesium oxide mineral insulation or mica tape winding to achieve fire-resistant functions. [0004] Magnesia mineral fire-resistant insulated cables have the following disadvantages in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L83/07C08L83/04C08K13/02C08K5/5419C08K3/22C08K3/04C08K3/34C08K3/40C08K3/38C08K3/32C08K3/26

Inventor 谭政新

Owner 东莞市朗晟材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com