Graphene oxide/aliphatic-aromatic copolyester and preparation method thereof

A graphene and aromatic technology, applied in the field of graphene oxide/aliphatic-aromatic copolyester and its preparation, can solve the problems of difficult degradation, environmental pollution, inability to be widely used in food and medicine fields, etc., and achieve high barrier properties. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

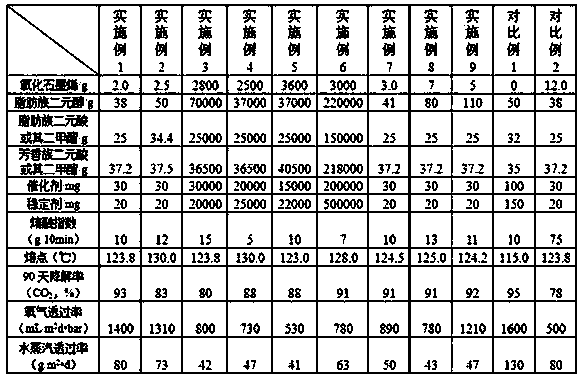

Examples

Embodiment 1

[0044] Add 2.0 g of graphene oxide into water, and ultrasonically disperse for 20 minutes, add 33.0 g of BDO under strong stirring, raise the temperature of the solution to 155-180 ° C, completely distill out the water in it, and make the hydroxyl group of the aliphatic dihydric alcohol and The carboxyl group of graphene oxide reacts to obtain graphene oxide / aliphatic glycol solution;

[0045] Add 5.0g of 1,4-cyclohexanedimethanol, 25.0g of adipic acid, 35g of terephthalic acid, and 2.2g of naphthalene dicarboxylic acid into the reaction kettle. Under nitrogen protection, raise the temperature to 210°C, and add n-butyl titanate 30 mg ester, keep the temperature in the reactor at 210°C, and remove the water produced by the reaction by splitting, and judge the degree of reaction by weighing the water generated by the reaction. When the esterification rate reaches 95%, after the temperature reaches 230°C, add Triphenyl phosphite 0.02g, react for 30 minutes, then start to slowly h...

Embodiment 2

[0048] Add 2.5g of graphene oxide into water, and ultrasonically disperse for 20 minutes, add 50.0g of BDO under strong stirring, raise the temperature of the solution to 155-180°C, completely distill out the water in it, and make the hydroxyl group of the aliphatic dihydric alcohol and The carboxyl group of graphene oxide reacts to obtain graphene oxide / aliphatic glycol solution;

[0049] Add 35.0g of terephthalic acid, 34.4g of sebacic acid and 2.5g of naphthalene dicarboxylic acid into the reaction kettle, under the protection of nitrogen, raise the temperature to 210°C, add 30mg of n-butyl titanate, and maintain the temperature in the reaction kettle at 210°C At the same time, the water produced by the reaction is removed by split flow, and the degree of reaction is judged by weighing the water generated by the reaction. When the esterification rate reaches 95%, after the temperature is lowered to 230 ° C, add 0.02 g of triphenyl phosphite and react for 30 minutes. , and t...

Embodiment 3

[0052] Add 2800g of graphene oxide into water, and ultrasonically disperse for 20 minutes, add 33kg of BDO under strong stirring, raise the temperature of the solution to 155-180°C, completely distill out the water in it, and make the hydroxyl group of the aliphatic dihydric alcohol and the graphite oxide The carboxyl group of ene is reacted to obtain graphene oxide / aliphatic dihydric alcohol solution;

[0053] Add 33kg of 1,4-butanediol, 4kg of 1,4-cyclohexanedimethanol, 34kg of terephthalic acid, and 2.5kg of naphthalene dicarboxylic acid into the reaction kettle, raise the temperature to 210°C under the protection of nitrogen, and add titanic acid 30g of n-butyl ester, keep the temperature in the reactor at 210°C, remove the water produced by the reaction by splitting, and judge the degree of reaction by weighing the water generated by the reaction. When the esterification rate reaches 95%, add 25kg of adipic acid, Maintain the reaction temperature at 210°C until the esteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com