Continuous casting used crystallizer casting powder for plate blank and preparing method thereof

A continuous casting mold and mold flux technology, applied in the field of continuous casting mold flux and its preparation for slabs, can solve the problems of reducing the type of base material, prone to segregation, instability, etc., and achieve strong adsorption of inclusions capacity, reducing serious pollution problems, and reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

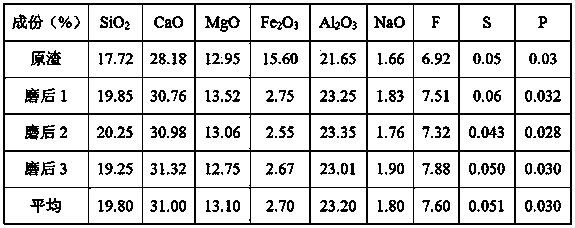

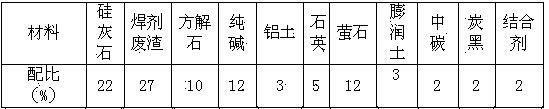

[0029] The flux waste slag formula in the above production process can be shown in the following table:

[0030]

[0031] If conventional raw materials are used, the formula is shown in the table below:

[0032]

[0033] From the comparison of the above data, it can be seen that 27% of the flux waste slag replaces 18% of wollastonite, 5% of cryolite, 4% of fluorite, 3% of calcite, 4% of magnesium powder, and 3% of bauxite in the conventional formula. , plus 5% soda ash and 5% quartz; the raw material cost of the conventional formula is 1253.5 yuan / ton, and the flux waste slag is calculated at 350 yuan / ton, and the raw material cost of the flux waste slag formula is 945.8 yuan, which reduces the raw material cost by 308.7 yuan / ton;

[0034] In the process ③ in the batching and slurrying, the slurrying time is 62min, and the water content of the slurry is 27%; ④The pump pressure of the spray granulation plunger pump is 2.2MPa, the liquid supply rate is 24mL / min, the flu...

Embodiment 2

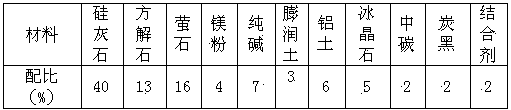

[0037] The flux waste slag formula in the above-mentioned production process can also be shown in the following table:

[0038]

[0039] If conventional raw materials are used, the formula is shown in the table below:

[0040]

[0041] From the comparison of the above data, it can be seen that 18% of flux waste slag replaces 3% of cryolite, 11% of wollastonite, 2% of calcite, 4% of coke gem, 2% of bauxite in the conventional formula, and 4% of quartz, 2% of bauxite are added. %NaF, the raw material cost of the conventional formula is 1129.5 yuan / ton, and the flux waste slag is calculated at 350 yuan / ton. The raw material cost of the flux waste slag formula is 874.3 yuan, and the raw material cost is reduced by 255.2 yuan / ton.

[0042] In the process ③ in the batching and pulping, the pulping time is 66min, and the water content of the slurry is 29%; ④The pump pressure of the spray granulation plunger pump is 2.4MPa, the liquid supply rate is 24mL / min, the fluidized be...

Embodiment 3

[0045] The flux waste slag formula in the above-mentioned production process can also be shown in the following table:

[0046]

[0047] If conventional raw materials are used, the formula is shown in the table below:

[0048]

[0049] From the comparison of the above data, it can be seen that 24% of the flux waste slag replaces 12% wollastonite, 5% fluorite, 9% calcium carbonate, 3% glass stone, 2% bauxite in the conventional formula, and 4% calcite and 3% quartz; the raw material cost of the conventional formula is 1214.6 yuan / ton, and the flux waste slag is calculated at 350 yuan / ton. The raw material cost of the flux waste slag formula is 948.4 yuan, which reduces the raw material cost by 286.2 yuan / ton.

[0050] In the process ③ in the batching and pulping, the pulping time is 70min, and the water content of the slurry is 30%; ④The pump pressure of the spray granulation plunger pump is 2.5MPa, the liquid supply rate is 24mL / min, and the fluidized bed The tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com