Vacuum packaging method for symmetric hot rolling manufactured stainless steel clad plates

A technology of vacuum packaging and stainless steel plate, which is applied in metal rolling, manufacturing tools, metal rolling, etc. It can solve the problems such as the influence of bonding strength and the inability to meet the technical requirements of stainless steel clad plate, so as to improve production efficiency and achieve good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

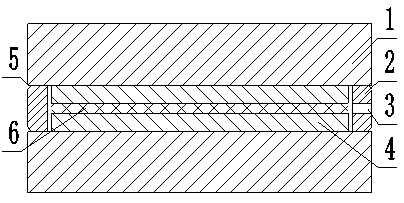

[0020] Such as figure 1 As shown, the outer surface of the seal 2 is flush with the outer surface of the low-carbon steel plate 1 , the weld of the seal 2 is provided with a groove, and the weld 5 is welded between the groove and the low-carbon steel plate 1 .

Embodiment 2

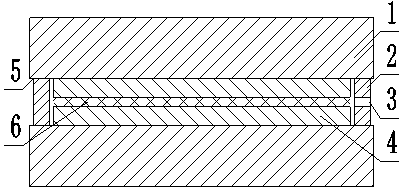

[0022] Such as figure 2 As shown, the outer surface of the seal 2 is lower than the outer surface of the low carbon steel plate 1, and the weld seam 5 is welded between the outer surface of the seal 2 and the inner surface of the low carbon steel plate 1.

[0023] Example 2

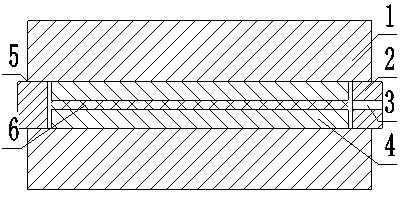

[0024] Such as image 3 As shown, the outer surface of the seal 2 is higher than the outer surface of the low carbon steel plate 1, and the weld seam 5 is welded between the inner surface of the seal 2 and the outer surface of the low carbon steel plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com