Preparation method for epoxy microcapsule by taking polyurethane as wall material

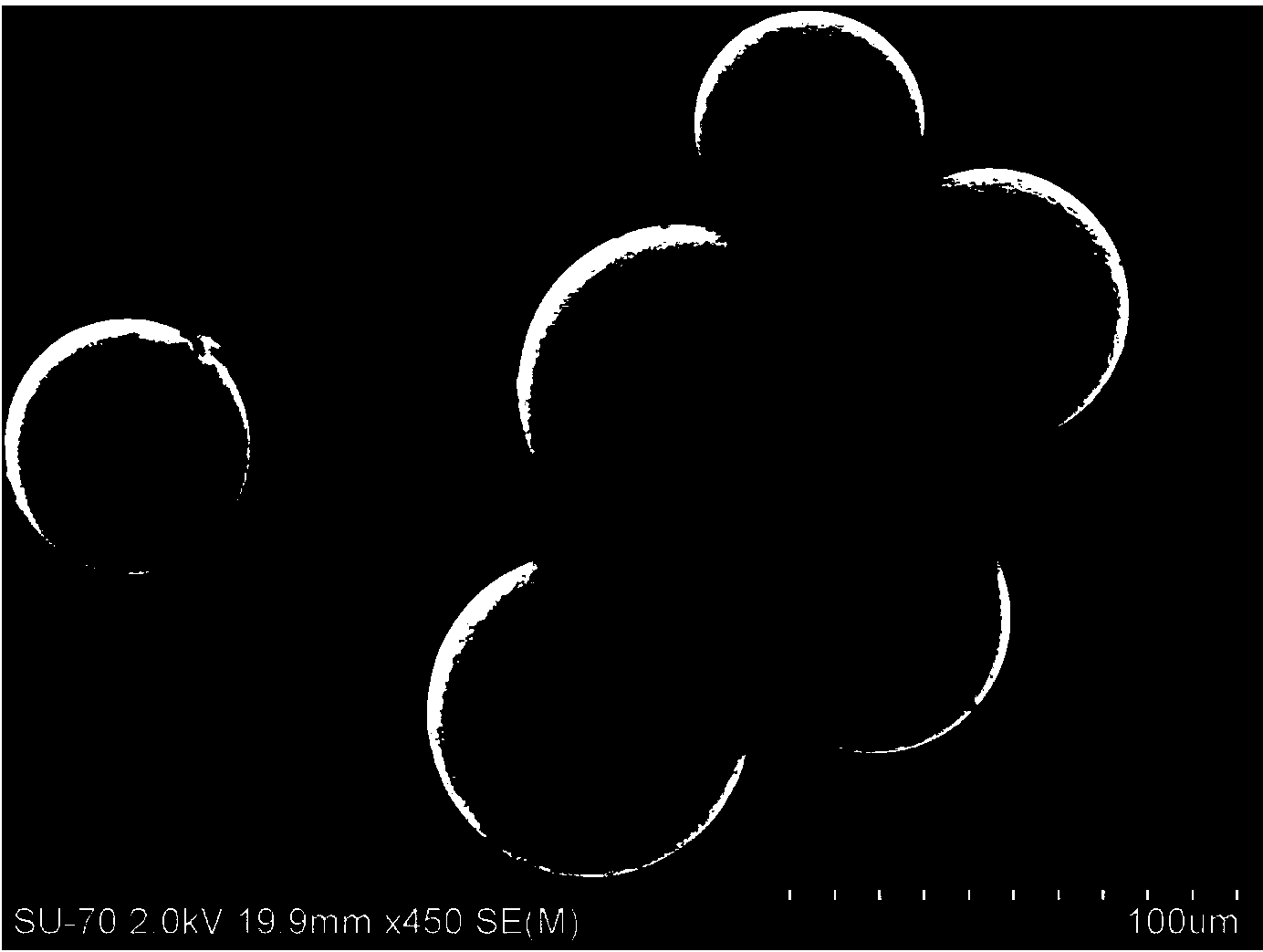

A polyurethane and microcapsule technology, applied in the field of self-healing concrete and self-healing materials, can solve problems such as difficult to achieve, and achieve the effects of uniform wall thickness, good sphericity and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The invention provides a kind of preparation method that takes polyurethane as the epoxy microcapsule of wall material, comprises the following steps:

[0012] S1: Preparation of polyurethane prepolymer terminated with isocyanate;

[0013] S2: Mix the isocyanate-terminated polyurethane prepolymer with epoxy resin, add emulsifier and water, stir and emulsify to make an oil-in-water emulsion;

[0014] S3: heating up, the interface reacts to form the capsule wall;

[0015] S4: filtering, rinsing the sediment with water, and drying to obtain microcapsules with polyurethane as the wall material and epoxy resin as the core material.

[0016] Specifically, the process of step S1 is: mix the hydroxyl compound, isocyanate, solvent, and catalyst, heat up to 50-80°C, stir and react at a speed of 100-500rpm for 2-3 hours to obtain a polyurethane prepolymer; the hydroxyl compound Dihydroxyl compounds or polyhydroxyl compounds are included; the isocyanate includes diisocyanate or p...

Embodiment 1

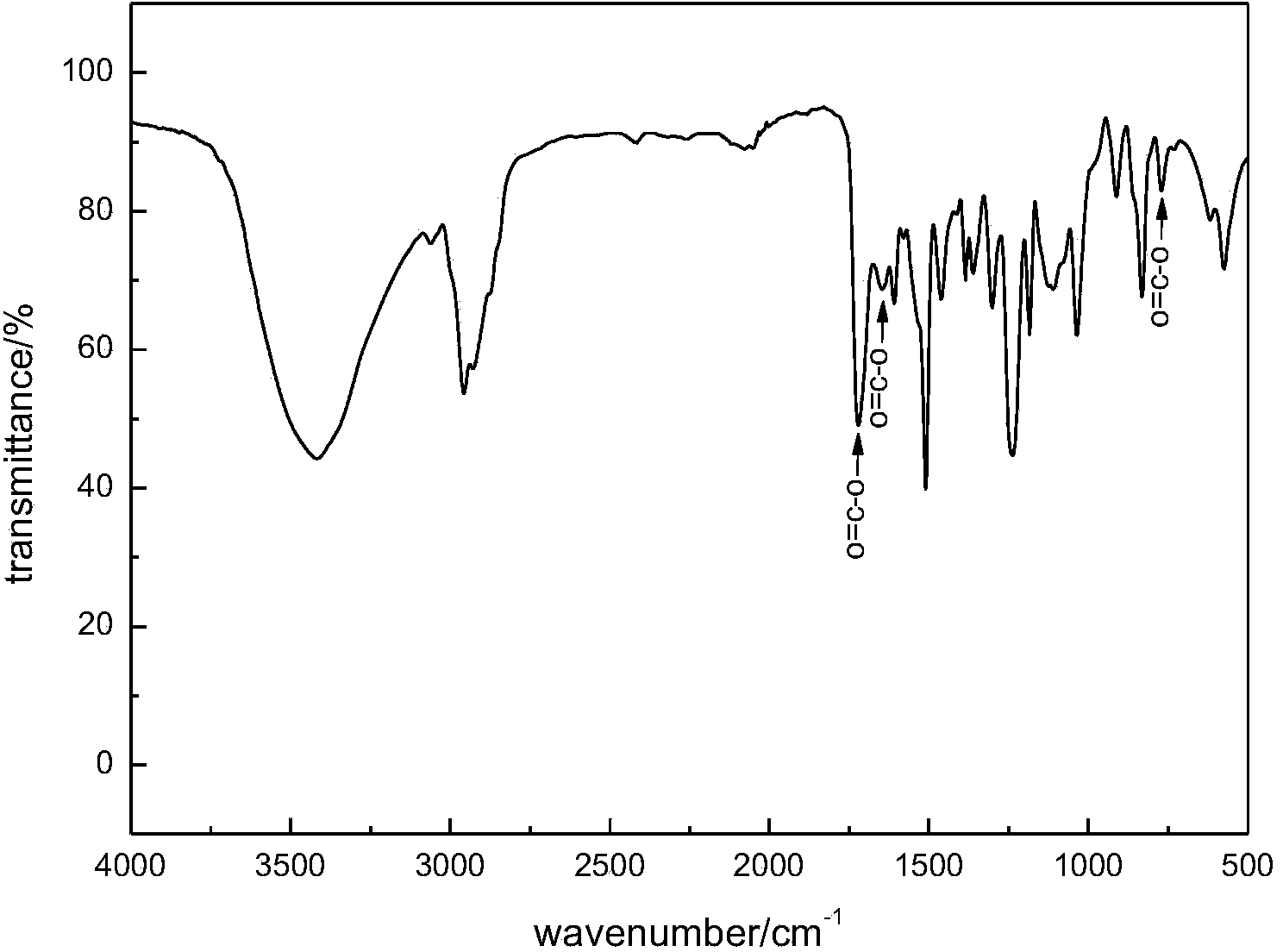

[0030] Take 1.38g of glycerol, 10g of IPDI, 5g of acetone, and 0.03g of catalyst DBTDL, mix them evenly, add them into a three-necked flask, stir and react at 60°C and 300rpm for 2-3h, and obtain a polyurethane prepolymer terminated with isocyanate; After mixing the prepolymer with 18g of epoxy E-51 evenly, add it to a three-necked flask filled with 100g of 1wt% PVA aqueous solution, emulsify at 20°C and 1000rpm for 10min, and keep it at 60°C for 1-2h. After cooling, the reaction solution was filtered, the filter cake was washed with distilled water, and then filtered three times, and then dried at 45°C for 12 hours to obtain polyurethane-coated epoxy microcapsules. Fourier transform infrared analysis was carried out on the microcapsules, and the experimental results are as follows: figure 1 As shown, there are characteristic absorption peaks of ester bonds (O=C-O) in polyurethane at 1720, 1650 and 773 cm-1, which proves that the wall material of the microcapsules prepared by ...

Embodiment 2

[0032] Take 3g of polyethylene glycol, 6g of IPDI, 5g of acetone, and 0.03g of catalyst DBTDL, mix them evenly, add them into a three-necked flask, stir and react at 60°C and 300rpm for 2-3 hours, and obtain a polyurethane prepolymer terminated with isocyanate; After mixing the prepolymer with 10g of epoxy E-51 evenly, add it to a three-necked flask filled with 100g of 1wt% PVA aqueous solution, emulsify at 20°C and 1000rpm for 10min, and keep it at 60°C for 1-2h. After cooling, the reaction solution was filtered, the filter cake was washed with distilled water, and then filtered three times, and then dried at 45°C for 12 hours to obtain polyurethane-coated epoxy microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com