Preparation method of hot-method polyvinylidene fluoride hollow fiber membrane for drinking water treatment

A polyvinylidene fluoride, drinking water treatment technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of low strength, poor toughness, short life, etc., to achieve stable performance, outstanding weather resistance The effect of high resistance and high retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the thermal process polyvinylidene fluoride hollow fiber membrane that is used for drinking water treatment that the present invention proposes, comprises the following steps:

[0024] (1) Dry polyvinylidene fluoride and polyethersulfone in a dryer respectively, the drying temperature is 80-90°C, and the drying time is 24-36 hours;

[0025] (2) Preparation of blended polymer solution for membrane production:

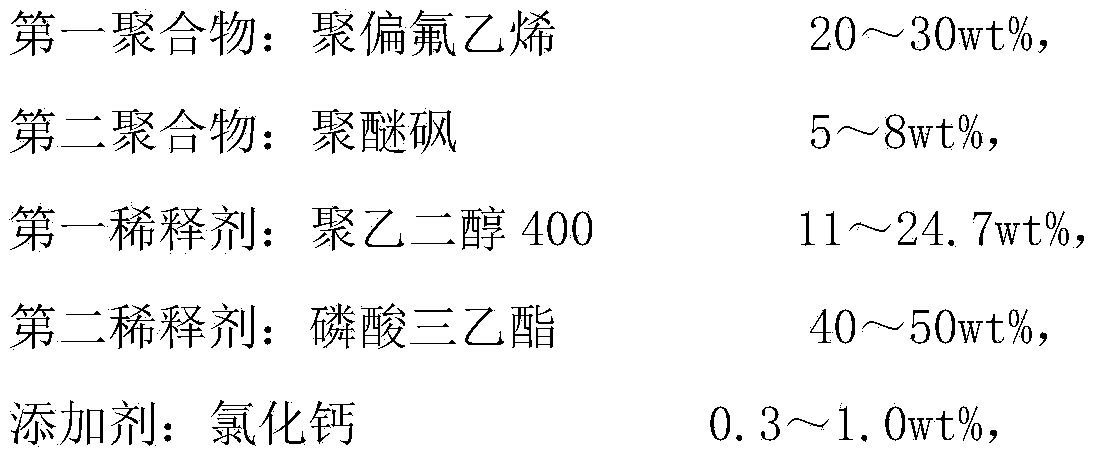

[0026] The mass percent of each component in the blended polymer solution is:

[0027]

[0028] After weighing polyvinylidene fluoride, polyethersulfone, polyethylene glycol 400, triethyl phosphate and calcium chloride according to the above ratio, put them in a stirring tank, stir and dissolve at a temperature of 140-155 °C, The stirring time is 14 to 16 hours, and the stirring speed is 90 to 110 rpm to make a uniform blended polymer solution;

[0029] (3) Extrusion and forming of hollow fiber membranes, the specific process is as f...

Embodiment 1

[0052] (1) Pretreatment of polymer materials:

[0053] Dry polyvinylidene fluoride PVDF (molecular weight: 370,000) and polyethersulfone (molecular weight: 50,000) respectively in a dryer at a drying temperature of 85°C.

[0054] (2) Preparation of blended polymer solution:

[0055] The dried polyvinylidene fluoride P 1 , polyethersulfone P 2 , polyethylene glycol 400D1, triethyl phosphate D 2 and additive CaCl 2 After weighing according to the mass percentage, it is placed in the batching kettle, and its mass percentage (wt%) is P 1 :P 2 :D 1 :D 2 :A=25:5:19.5:50:0.5, stirring and dissolving at a temperature of 150°C for 15 hours at a stirring speed of 100 rpm to dissolve into a uniform blended polymer solution;

[0056] (3) Extrusion and forming of hollow fiber membrane:

[0057] (3-1) Send the blended polymer solution in step (2) into the twin-screw extruder through the spinning pump, the feeding speed of the raw material is 15 kg / hour, and the temperature of the 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com