Positive electrode active material for electrical devices, positive electrode for electrical devices, and electrical devices

A positive electrode active material and technology of active material, applied in the field of positive electrode active material, positive electrode for electrical devices and electrical devices, can solve the problem of inability to maintain high capacity, discharge capacity, insufficient initial rate characteristics of discharge working voltage, lithium-nickel-manganese composite oxidation The crystal structure cannot be stabilized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

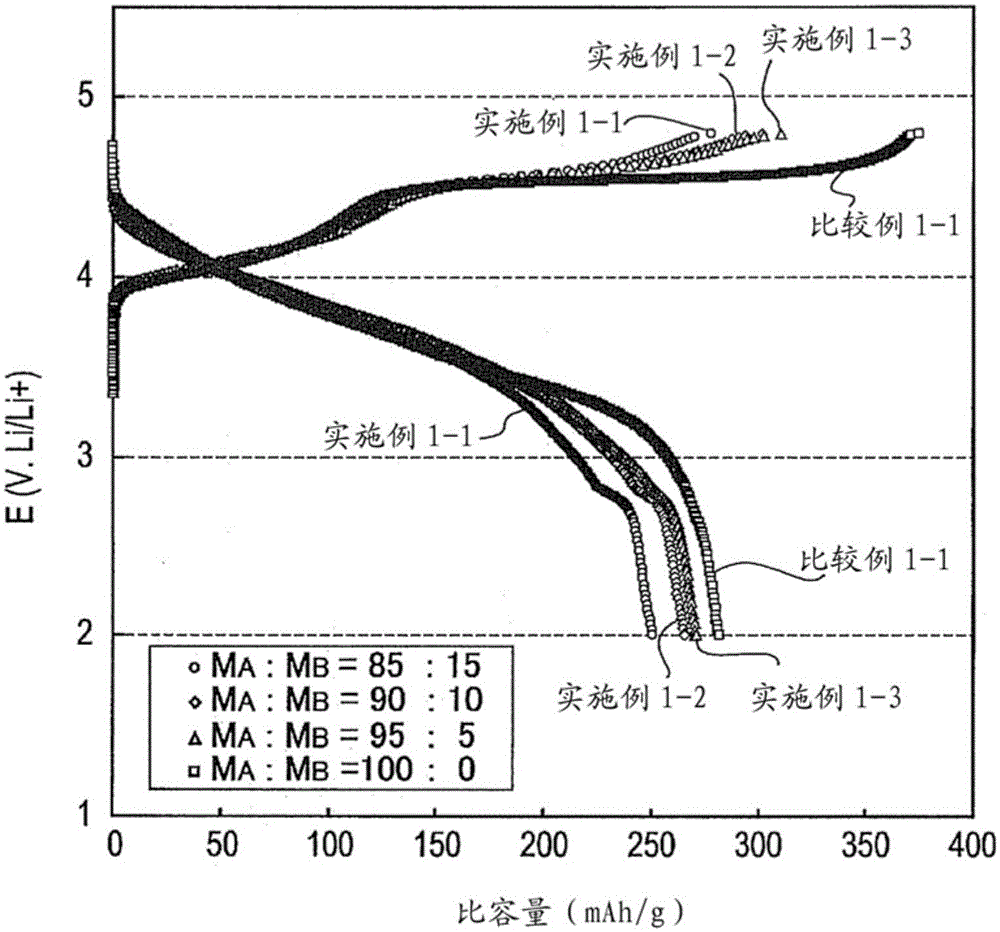

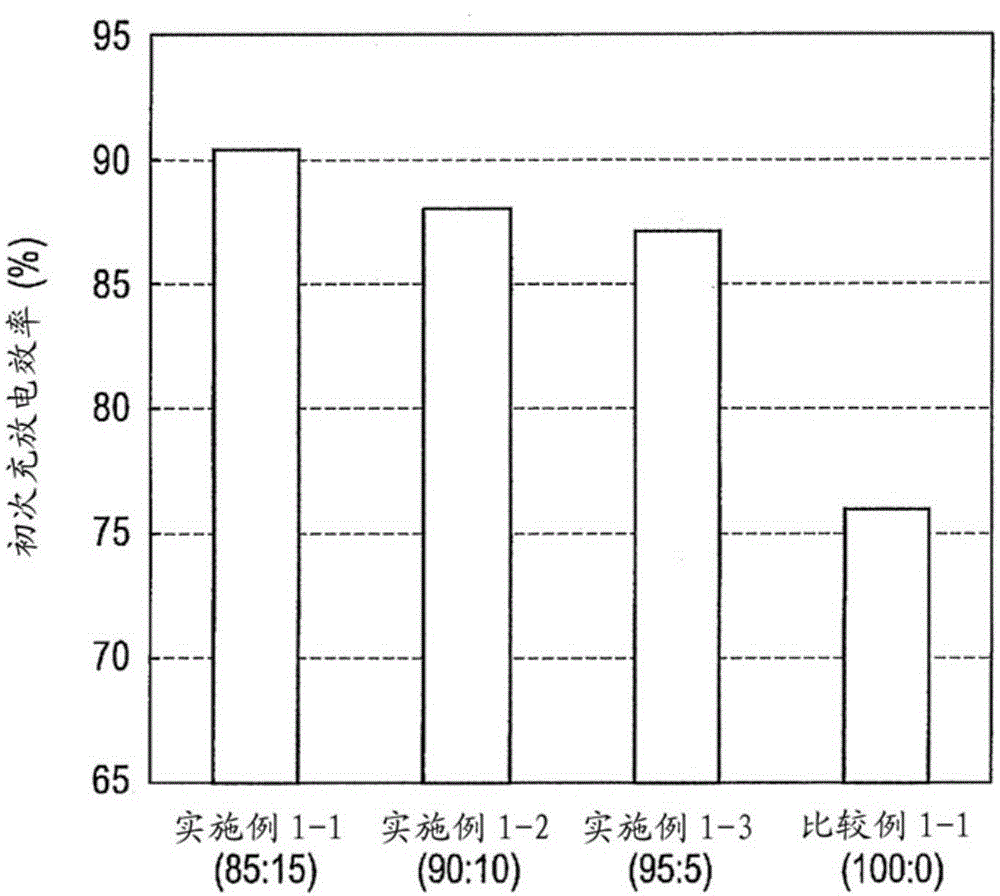

[0033] First, a positive electrode active material for a lithium ion secondary battery according to a first embodiment of the present invention will be described. The positive electrode active material for a lithium ion secondary battery according to the first embodiment contains a first active material composed of a transition metal oxide represented by composition formula (1). Furthermore, the positive electrode active material includes a second active material composed of a spinel-type transition metal oxide represented by the composition formula (2) and having a crystal structure belonging to the space group Fd-3m.

[0034] Li 1.5 [Ni a co b mn c [Li] d ]O 3 (1)

[0035] In formula (1), Li represents lithium, Ni represents nickel, Co represents cobalt, Mn represents manganese, and O represents oxygen. In addition, a, b, c, and d satisfy the relationships of 0<d<0.5, a+b+c+d=1.5, and 1.0<a+b+c<1.5.

[0036] Li M a’ mn 2-a’ o 4 (2)

[0037] In the formula (2), Li...

Embodiment 1

[0122] Hereinafter, the present embodiment will be further described in detail with examples and comparative examples, but the present invention is not limited to these examples.

Embodiment 1-1

[0124]

[0125] The first active material (solid solution) is synthesized by the composite carbonate method. Specifically, nickel, cobalt, and manganese sulfates were used as starting materials, and ion-exchanged water was added to each sulfate to prepare various 2 mol / L aqueous sulfate solutions. Next, various aqueous sulfate solutions were weighed and mixed so that nickel, cobalt, and manganese had a predetermined molar ratio, and a mixed aqueous sulfate solution was prepared.

[0126] Then, while stirring the mixed sulfate solution with a magnetic stirrer, dropwise inject sodium carbonate (Na 2 CO 3 ) aqueous solution to precipitate Ni-Co-Mn composite carbonate. In addition, infusion of sodium carbonate (Na 2 CO 3 ) aqueous solution, use 0.2mol / L ammonia solution as a pH regulator to adjust the pH value of the mixed sulfate solution to 7. Furthermore, the obtained composite carbonate was subjected to suction filtration, washed with water, dried at 120° C. for 5 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com