A back-contact silicon cell, its non-light-receiving surface treatment method, and its preparation method

A technology of crystalline silicon cells and light-receiving surfaces, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency of crystalline silicon cells, and achieve the goal of increasing photoelectric conversion efficiency, improving utilization efficiency, and high photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

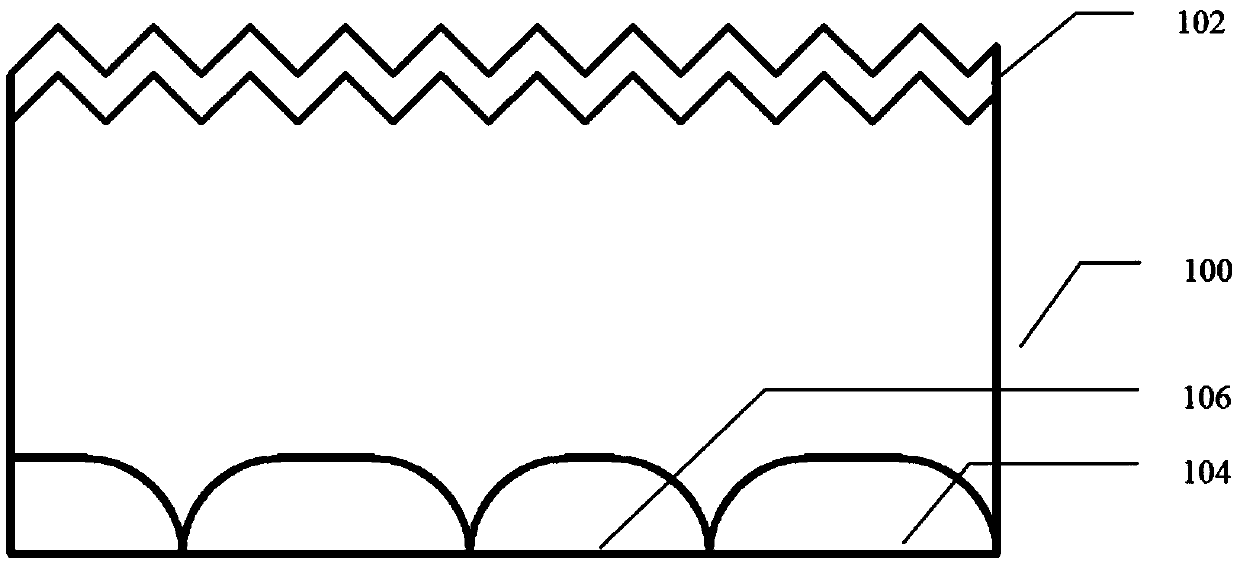

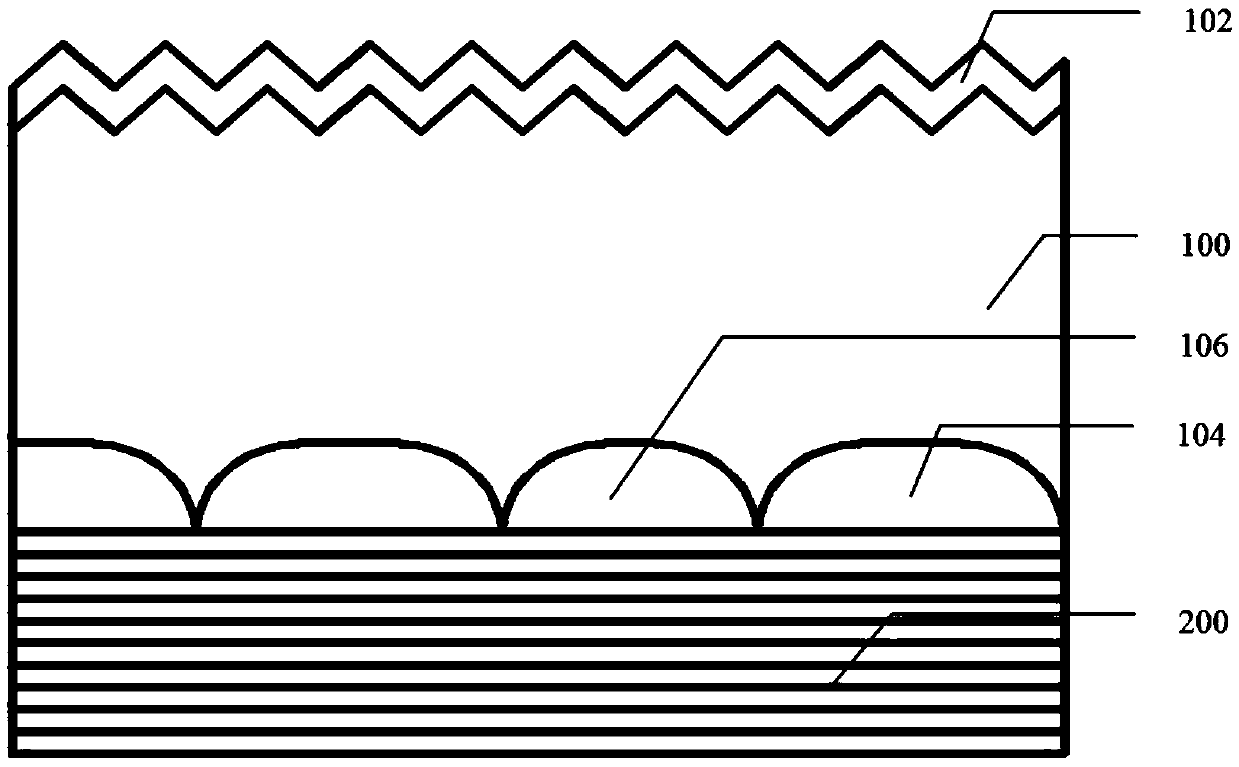

[0056] This embodiment provides a back contact crystalline silicon battery, such as Figure 2-4 As shown, a silicon substrate 100 is included. The silicon substrate 100 has a light-receiving surface and a non-light-receiving surface. On the non-light-receiving surface, a P-type region busbar conductive strip 108 and an N-type region busbar conductive strip 112 are arranged in a PNPN type. In an arrangement structure, the P-type region bus conductive tape 108 is connected to the positive metal electrode 110, and the N-type region bus conductive tape 112 is connected to the negative metal electrode, covering the P-type region bus conductive tape 108 and the N-type region The bus conductive strip 112 is arranged on the five-layer Bragg reflective layer 200 on the non-light-receiving surface, the Bragg reflective layer 200 is arranged along the thickness direction of the crystalline silicon cell, and each layer of the Bragg reflective layer 200 includes a first A first Bragg reflec...

Embodiment 2

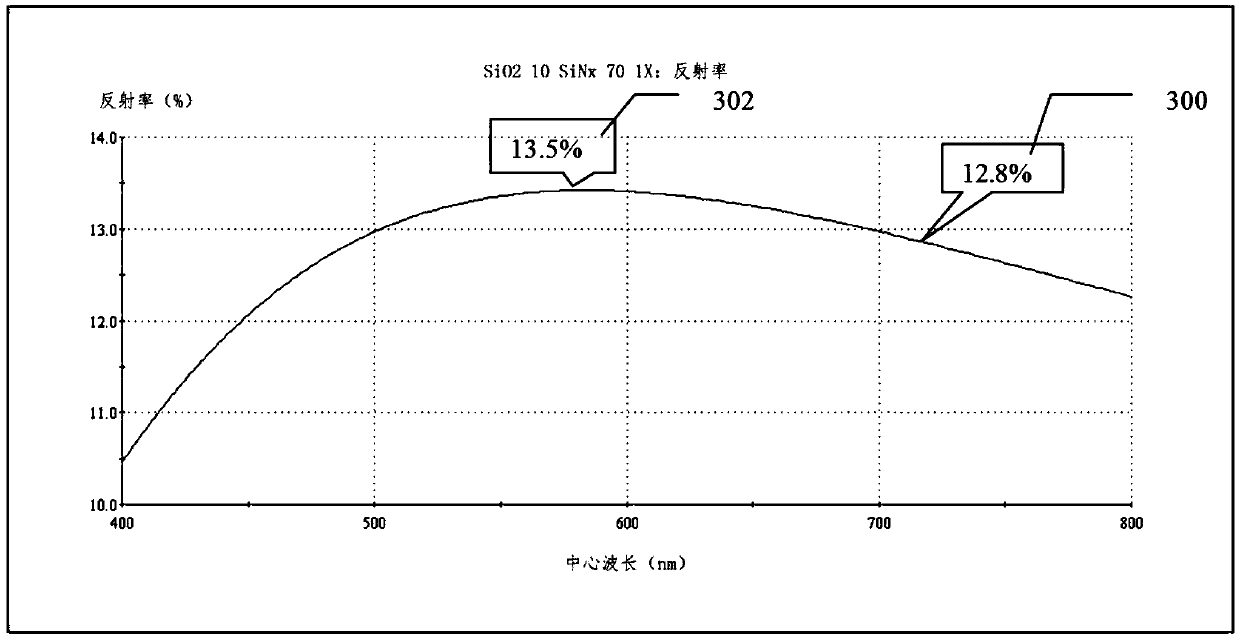

[0060] This embodiment provides a back contact crystalline silicon cell, which is a modification on the basis of Embodiment 1. The difference is that in this embodiment, light with a central wavelength λ=600nm is taken as the target reflected light, and the formula d1=d2 =1 / 8λ calculates d1=d2=75nm. According to this data, 5 layers of the above-mentioned Bragg reflective layer 200 are deposited on the non-light-receiving surface. The data obtained by the test is as follows Image 6 As shown, the maximum reflectivity 302 for light with a wavelength in the range of 400-800nm is 65%, and the average reflectivity 300 is 30%, and Figure 5 The data in is not much different, but the reflection effect is greatly enhanced compared with the reflection effect of the existing passivation layer.

[0061] As a modification of this embodiment, the above-mentioned Bragg reflective layer 200 can be provided with 2-8 layers, which can achieve the purpose of the invention.

Embodiment 3

[0063] This embodiment provides a back contact crystalline silicon battery, which is a modification on the basis of Embodiment 1. The difference is that the first material in this embodiment is SiO 2 , The thickness of the first Bragg reflective film formed by it is d1, and the second material is TiO 2 , The thickness of the second Bragg reflective film formed by it is d2, where SiO 2 Refractive index n 1 =1.46, TiO 2 Refractive index n 2 =2.35.

[0064] Take the center wavelength as λ 1 =500nm and λ 2 =800nm light is reflected by two targets, and through the formula d1=(2λ 1 -λ 2 ) / (2n 1 ), d2=(λ 2 -λ 1 ) / (2n 2 ) Respectively calculated d1=68.2nm, d2=78.9nm. According to this data, 5 layers of the above-mentioned Bragg reflective layer 200 are deposited on the non-light-receiving surface. The measured data are as follows Figure 7 As shown, the maximum reflectance 302 for light with a wavelength in the range of 400-800 nm is 93%, and the average reflectance 300 is about 50%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com