An integrated circuit board for a single-phase guide rail meter

A circuit board, integrated technology, used in printed circuit parts, parts of electrical measuring instruments, measuring devices, etc., can solve the problems of poor accuracy and stability of electric meters, low degree of automation, high process defect rate, and achieve accuracy stability. The effect of strong, high degree of automation and low process defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

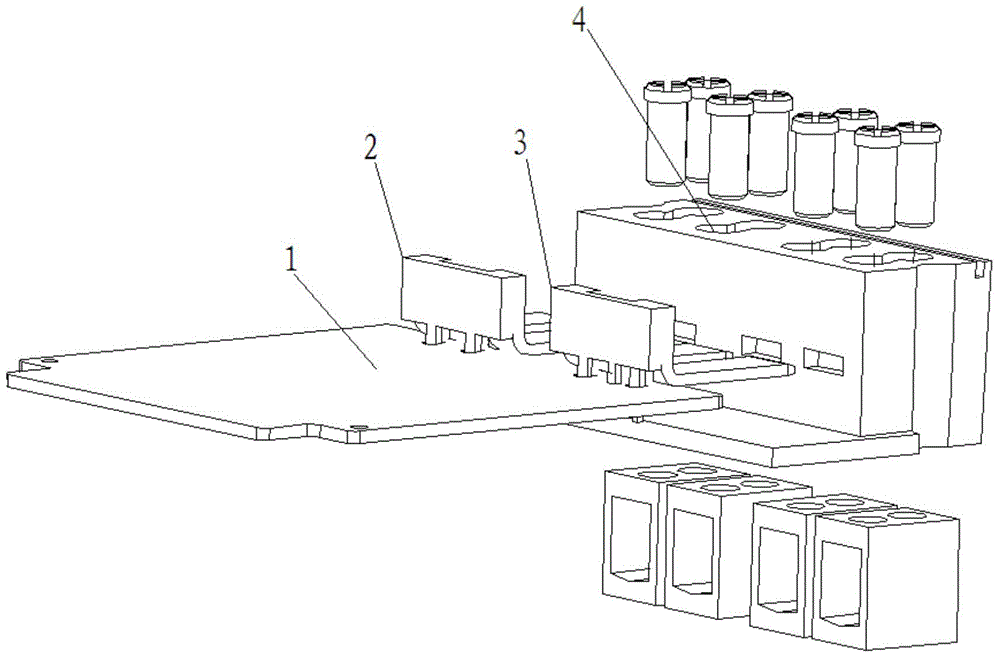

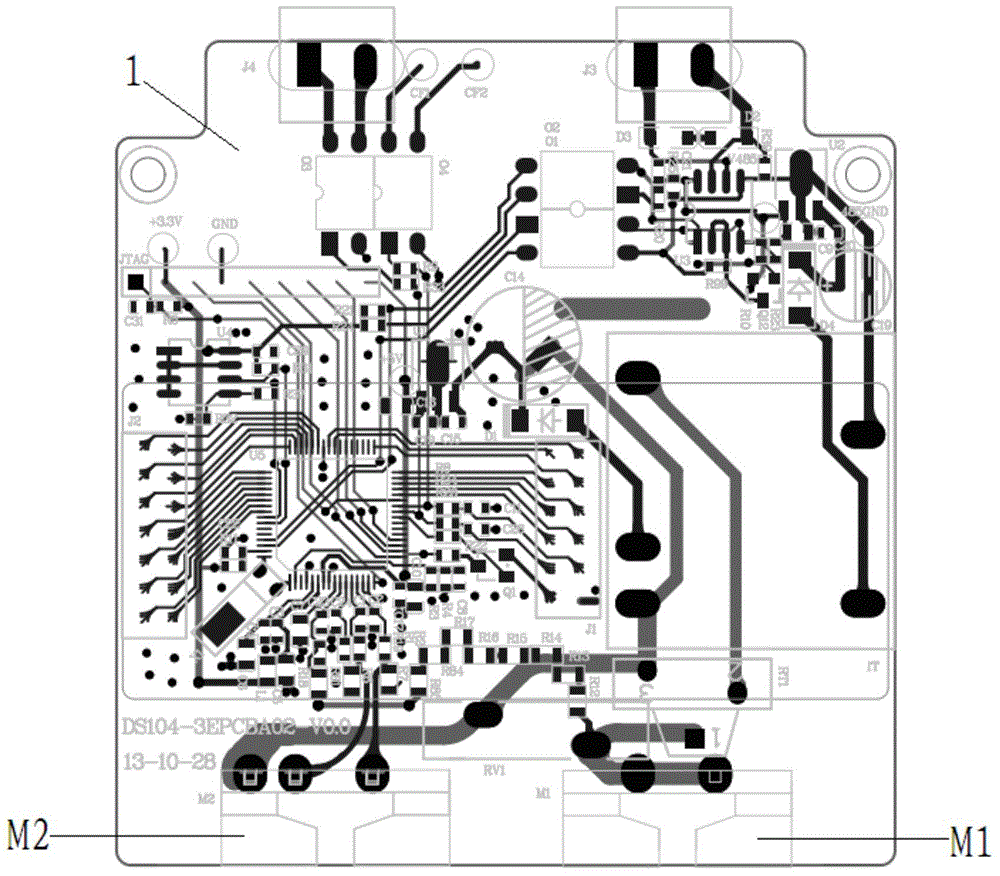

[0017] The integrated circuit board main structure of the single-phase guide rail meter involved in this embodiment includes a circuit board substrate 1, a manganese-copper shunt 2, a neutral line connecting piece 3 and a cage-type terminal seat 4, and the manganese-copper shunt 2 corresponds to the circuit board substrate 1 The bit number M2 at the lower left end is fixedly welded on the circuit board substrate 1 to realize the live wire power supply connection and current signal sampling; the zero line connection piece 3 corresponds to the position number M1 at the lower right end of the circuit board substrate 1 and is fixedly welded on the circuit board substrate 1 , realize the connection of the neutral line power supply, and form an integrated circuit board; the respective L-shaped copper sheets of the manganin shunt 1 and the neutral line connecting piece 2 on the integrated circuit board are respectively inserted into the jacks of the cage-type terminal block 4 In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com