A kind of mems humidity sensor and preparation method

A humidity sensor and comb-tooth technology, which is applied in the direction of instruments, scientific instruments, and manufacturing microstructure devices, etc., can solve problems such as poor performance, difficulty in integration, and performance degradation, and achieve simple preparation process, strong process compatibility, and easy integration The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

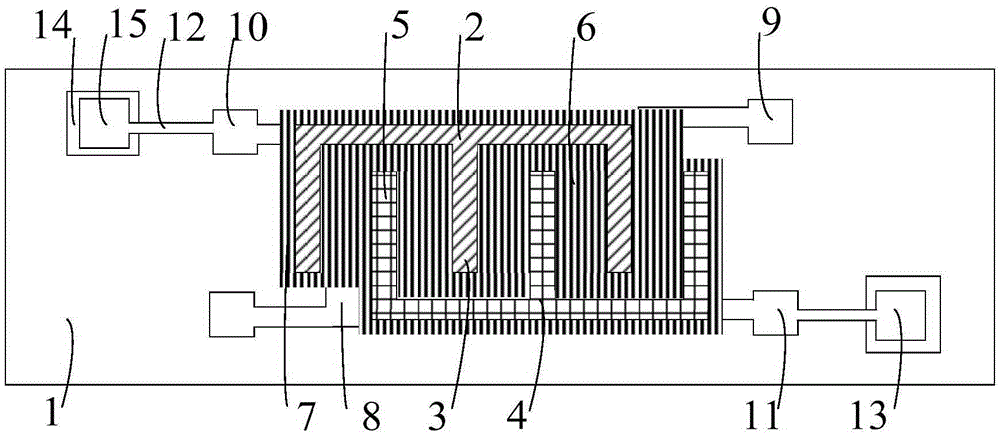

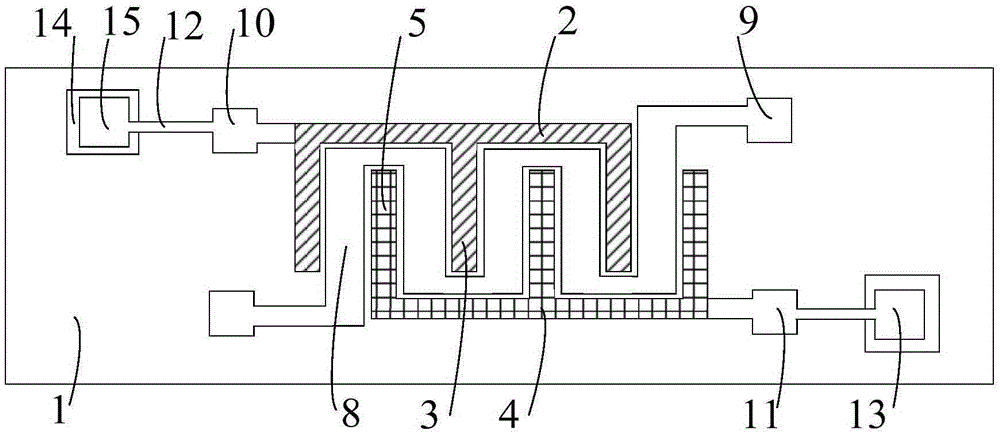

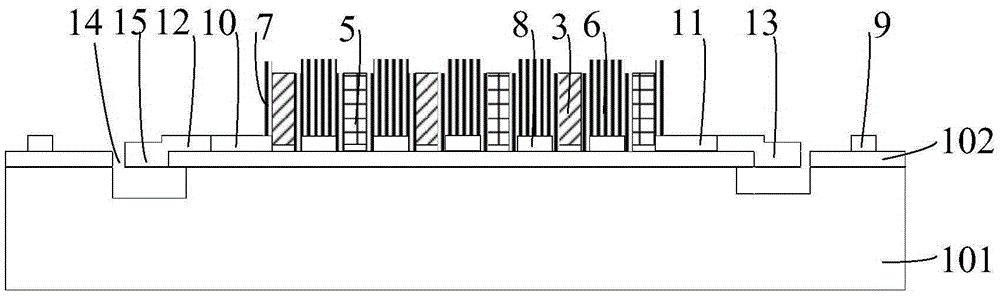

[0049] Figures 1 to 3 It is a structural schematic diagram of the MEMS humidity sensor provided in this embodiment. As shown in the figure, the MEMS humidity sensor includes a support base 1 , an electrical isolation layer 102 disposed on the support base 1 , and a comb assembly disposed on the electrical isolation layer 102 .

[0050] The comb-tooth assembly includes a first comb-tooth connecting electrode 2, a first comb-tooth 3, a second comb-tooth connecting electrode 4 and a second comb-tooth 5 arranged on the electrical isolation layer 102, and the first comb-tooth connecting electrode 2 is connected to There is a first comb-teeth test electrode 10, the second comb-teeth connection electrode 4 is connected to a second comb-teeth test electrode 11, and the first comb-teeth test electrode 10 is connected to the first conductive electrode 15 through an electrode connection line 12, The two comb-teeth test electrodes 11 are connected to the second conductive electrode 13 v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com