Application of ochrobactrum in preparation of microbial fuel cell, and device and method for preparing microbial fuel cell

A pale bacillus and fuel cell technology, applied in the field of biochemical fuel cells, can solve the problems of hindering electricity production capacity, electricity producing bacteria and unclear electricity production mechanism, and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take the Ochrobactrum sp.575 preserved in the laboratory, pick a single colony after streak culture and inoculate it into xylose medium, and culture it anaerobically at 37°C for 10 hours to OD 600 =0.8-1.0, then centrifuge the bacterial solution at 6000r / min, 4°C for 5 minutes to collect the bacterial cells, then re-add fresh xylose medium, mix well to make a bacterial suspension, and make the bacterial suspension OD 600 is 1.2.

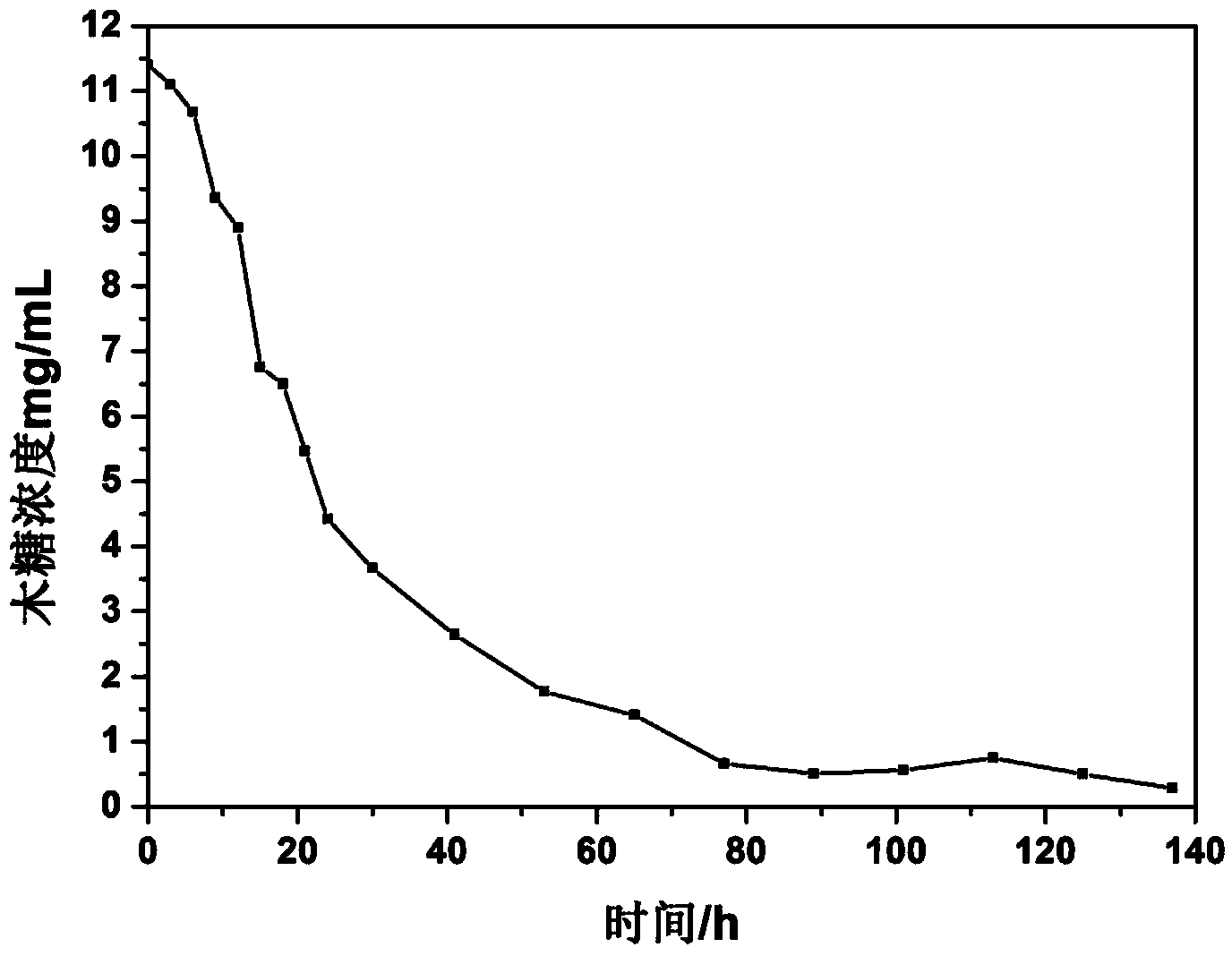

[0035] Start the microbial fuel cell (Microbial Fuel Cell, MFC). The microbial fuel cell used in this example is two cylindrical pools (the effective volume of each pool is 100mL), with a layer of proton exchange membrane in between, and the two pools are connected by clips. together, and then sealed with a rubber stopper; the carbon brush is used as the anode and the cathode, and the titanium wire is used as the electronic current collector; the prepared bacterial suspension is added to the anode cavity of the microbial fuel cell, and then ni...

Embodiment 2

[0041] After the streak culture of three domesticated Pallidum pallidus obtained in Example 1, a single colony was inoculated into xylose medium, and anaerobic culture was carried out at 37°C for 10 hours to OD 600 =0.8-1.0, then centrifuge the bacterial solution at 6000r / min at 4°C for 5 minutes, collect the bacterial cells, add fresh xylose medium to the bacterial cells, mix well to make a bacterial suspension, and control the bacterial suspension OD 600 is 1.2.

[0042]Start the microbial fuel cell. The microbial fuel cell consists of two cylindrical pools (the effective volume of each pool is 100mL), with a layer of proton exchange membrane in between. The two pools are connected together by clips and sealed with rubber plugs; the carbon brush is used as the anode And cathode, use titanium wire wire as electronic current collector. The above-mentioned bacterial suspension is added into the anode chamber of the microbial fuel cell, and nitrogen gas is passed for 30 minute...

Embodiment 3

[0048] After the streak culture of three domesticated Pallidum pallidus obtained in Example 1, a single colony was inoculated into xylose medium, and anaerobic culture was carried out at 37°C for 10 hours to OD 600 =0.8-1.0, then take the bacterial solution and centrifuge at 6000r / min, 4°C for 5 minutes to collect the bacterial cells, then add the bacterial cells to fresh xylose medium, mix well to make a bacterial suspension, and control the bacterial suspension Liquid OD 600 is 1.2. At the same time, the cells were centrifuged in the same way and added to xylose-free medium to obtain a bacterial suspension as a control, and the fresh xylose medium that was not inoculated with cells was used as a blank control.

[0049] Add the above-mentioned bacterial suspension or xylose medium into the electrolytic cell respectively, and use an electrochemical workstation (CHI660E, Shanghai Chenhua) to perform a constant potential (0.2V) simulated discharge on the bacterial liquid for 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com