Method for preparing activated carbon from coal tar residues and application thereof

A technology for preparing activated carbon and coal tar, which is applied in the fields of chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc. It can solve the problems of unsatisfactory high-pollution water treatment, limited specific surface area and adsorption performance, and limited water purification capacity. , to achieve the effect of relatively low cost, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Coal tar residue and potassium hydroxide activator are mixed evenly at a mass ratio of 1:3, then transferred to a high-temperature furnace, and reacted for 1 hour at a temperature of 800°C under the protection of an inert atmosphere of nitrogen;

[0033] Then cool, wash with 2M dilute hydrochloric acid solution until the pH value is 6-7, and dry to obtain the coal tar porous activated carbon material;

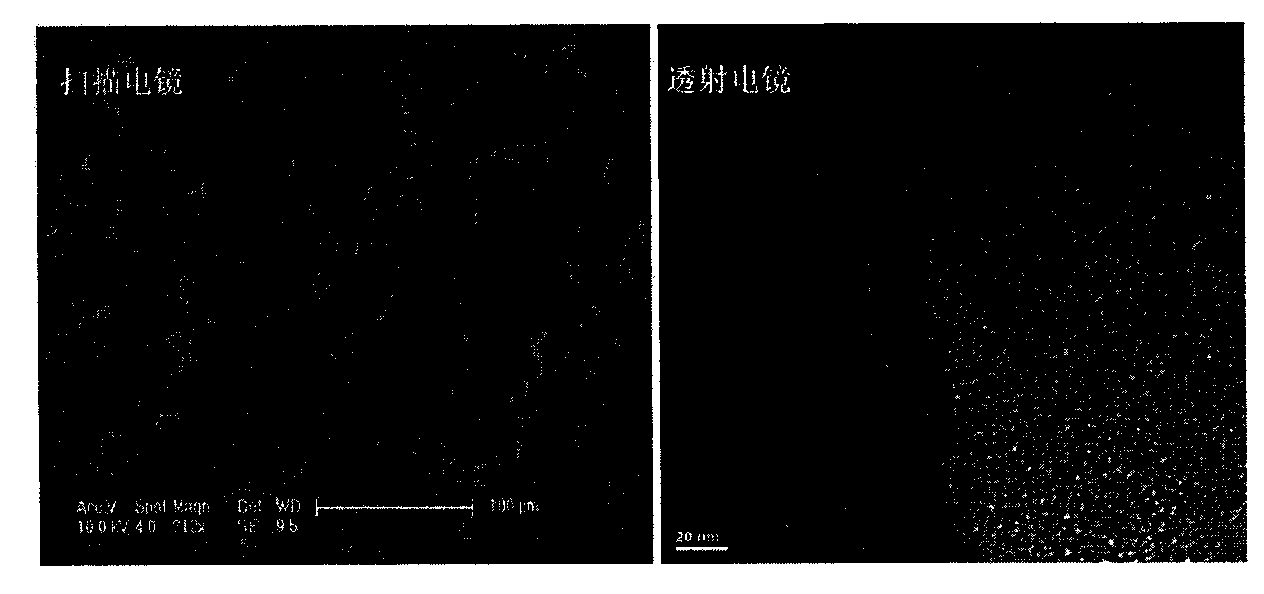

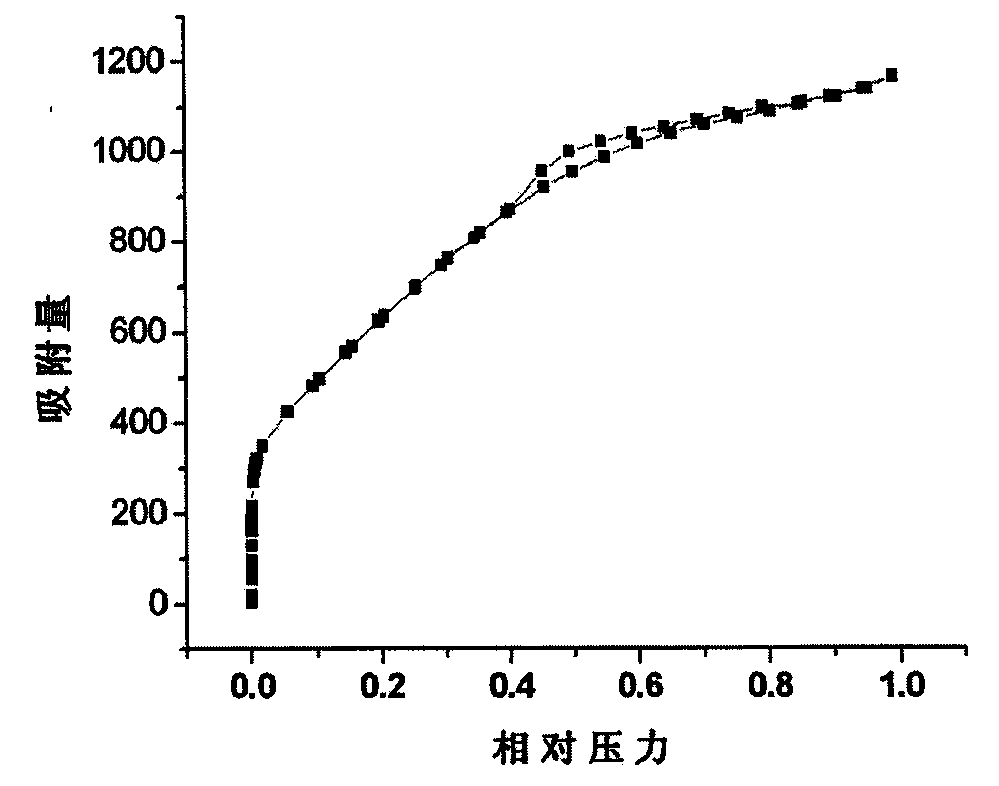

[0034] Characterization results of the physical and chemical properties of the obtained coal tar porous carbon materials using scanning electron microscopy, transmission electron microscopy, infrared, and elemental analyzers figure 1 , figure 2 ; Carry out adsorption test and supercapacitor test to the obtained coal tar porous activated carbon material, the result image 3 and Figure 4 ;

[0035] figure 1 , figure 2 and image 3 The results show that the obtained coal tar porous activated carbon material has a specific surface area of 3290.23m 2 g -1 , the p...

Embodiment 2

[0037] Mix the coal tar residue and zinc chloride uniformly at a mass ratio of 1:4, transfer to a high-temperature furnace, and react for 2 hours at a temperature of 500° C. under the protection of an inert atmosphere of nitrogen;

[0038] Then cool, wash with 2M dilute hydrochloric acid solution until the pH value is 6-7, and dry to obtain the coal tar porous activated carbon material;

[0039] The specific surface area of coal tar porous activated carbon material obtained by nitrogen adsorption and desorption analysis and elemental analyzer detection is 1120m 2 g -1 , the pore size is mainly micro-mesopores smaller than 1-6nm; the mass percentage of elemental analysis is carbon 90.55%, oxygen 1.29%, nitrogen 7.9%, as shown in the table. The adsorption iodine value is 400mg / g, the adsorption methylene blue value is 100mg / g, and the supercapacitor test result is 130Fg -1 ;

[0040] surface

[0041]

Embodiment 3

[0043] Mix the coal tar residue and sodium hydroxide evenly with a mass ratio of 1:4, transfer to a high-temperature furnace, and react for 3 hours at a temperature of 600°C under the protection of an inert atmosphere of nitrogen;

[0044] Then cool, wash with 2M dilute nitric acid solution until the pH value is 6-7, and dry to obtain the coal tar porous activated carbon material;

[0045] The specific surface area of coal tar porous activated carbon material obtained by nitrogen adsorption and desorption analysis and elemental analyzer detection is 2300m 2 g -1 , the pore size is mainly micro-mesoporous; elemental analysis mass percentage is carbon 90.3%, oxygen 4.7%, nitrogen 0.4%. The adsorption iodine value is 1300mg / g, the adsorption methylene blue value is 400mg / g, and the supercapacitor test result is 210Fg -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com