Preparation method of nitrogenous porous carbon

A technology of porous carbon and pre-oxidation, applied in the field of porous materials, can solve the problems of poor economy, low surface area, complicated operation, etc., and achieve the effects of low production cost, abundant sources and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

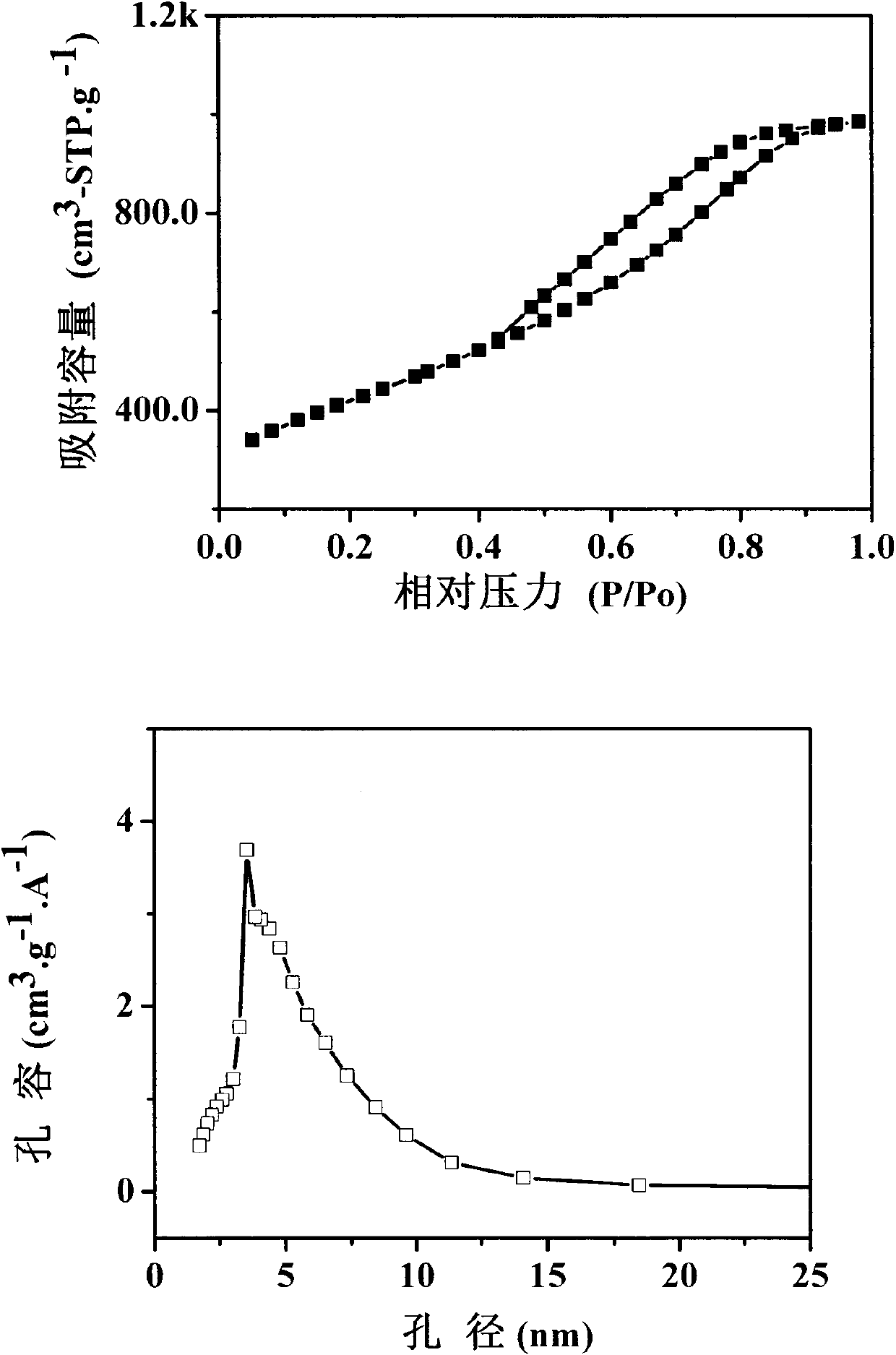

Embodiment 1

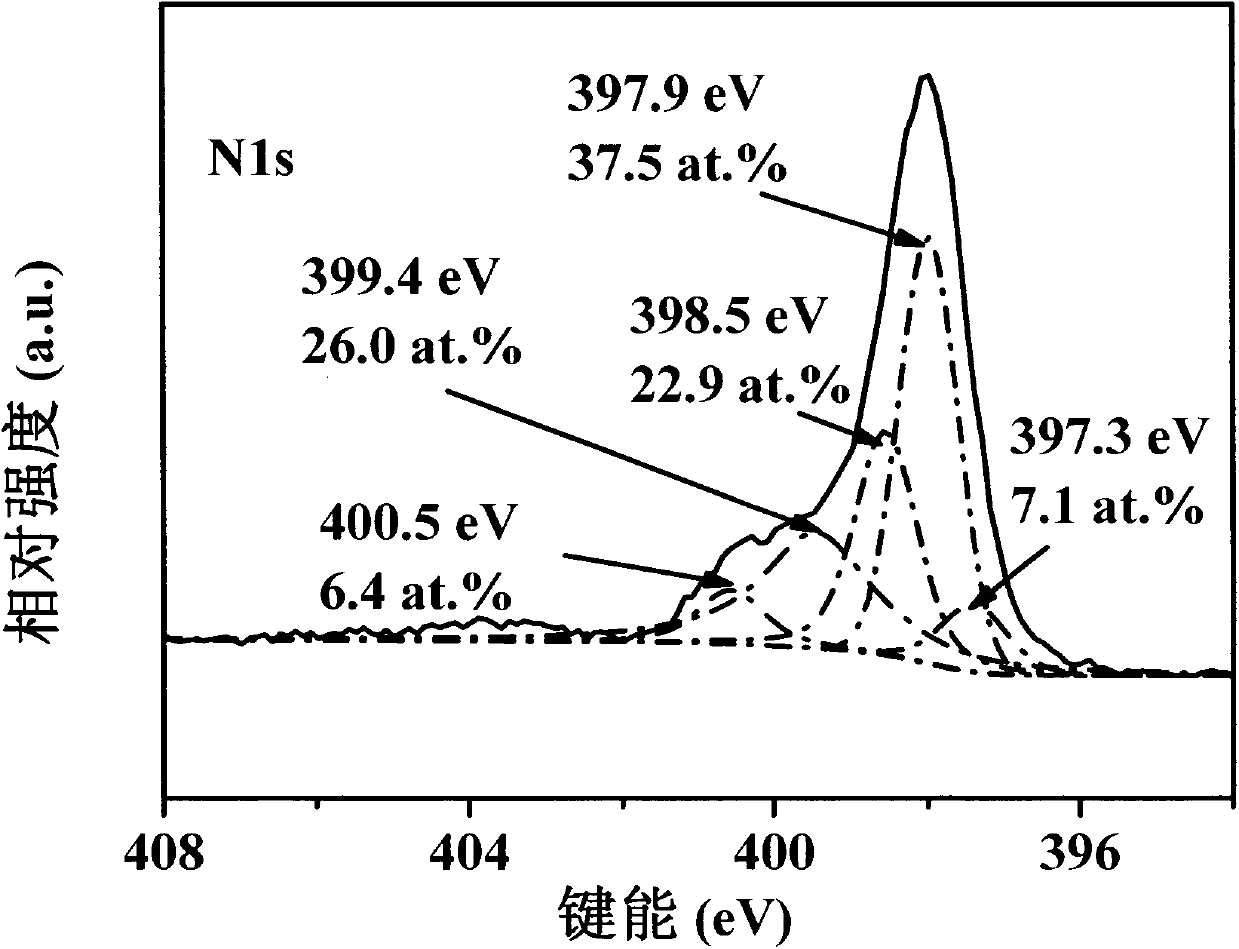

[0023] Mix 5g of mesoporous carbon with 1 times the volume of hydrogen peroxide solution with a concentration of 0.1M, let stand for 24h, filter, wash and dry to obtain pre-oxidized mesoporous carbon; weigh 50g of melamine and 5g of pre-oxidized mesoporous carbon, and mix the two Place them at both ends of the reaction container, and separate them with a spacer in the middle; cover and seal the container, place it in a heating furnace, heat it to 350°C in a nitrogen atmosphere, keep it warm for 4 hours, then raise the temperature to 525°C, keep it warm for 4 hours, and naturally After cooling, nitrogen-containing porous carbon is obtained, with a surface area of 1150m 2 / g, total pore volume 1.50cm 3 / g, the average pore diameter is 4.1nm, the mesoporosity is 100%, and the nitrogen content is 17at% (atomic %).

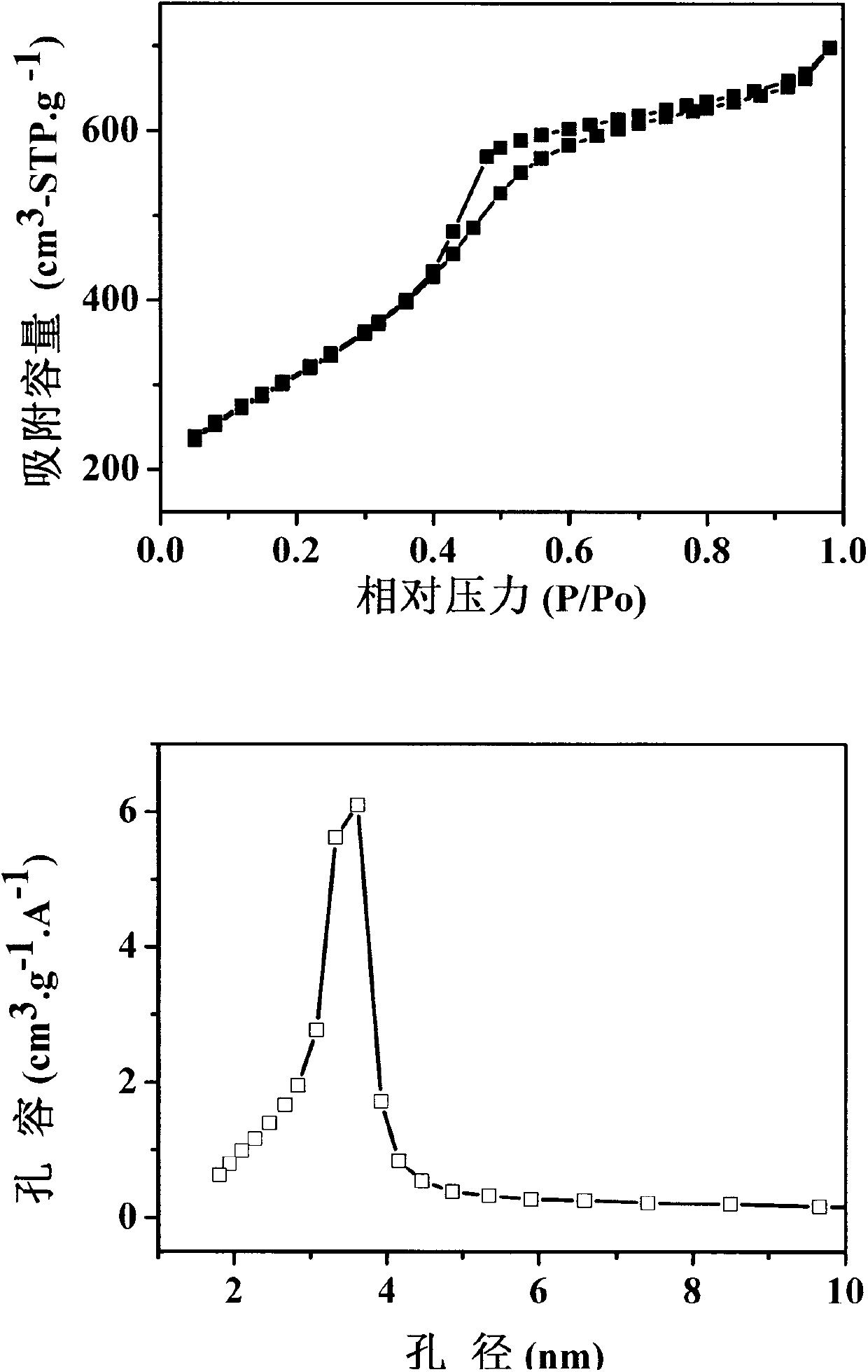

Embodiment 2

[0025] Mix 5g ordered mesoporous carbon (CMK-3) with 10 times the volume of 5M nitric acid solution, let it stand for 1h, filter, wash and dry to obtain preoxidized CMK-3; weigh 5g melamine, 5g preoxidized CMK-3, place the two at both ends of the reaction vessel, and separate them with a ceramic spacer in the middle; cover and seal the vessel, place it in a heating furnace, heat it to 500°C in a nitrogen atmosphere, keep it warm for 0.1h, and then raise the temperature To 725 ℃, keep warm for 0.1h, after natural cooling, nitrogen-containing porous carbon is obtained, and its surface area is 1100m 2 / g, total pore volume 1.10cm 3 / g, the average pore diameter is 3.8nm, the mesoporosity is 99%, and the nitrogen content is 10at% (atomic %).

Embodiment 3

[0027] Mix 10g of bamboo activated carbon with 5 times the volume of potassium permanganate solution with a concentration of 2M, filter, wash and dry to obtain pre-oxidized bamboo activated carbon after standing for 2 hours; weigh 1g of melamine, 10g of pre-oxidized bamboo activated carbon, Put melamine and porous carbon at both ends of the reaction vessel, and separate them with a ceramic spacer in the middle; cover and seal the vessel, place it in a heating furnace, heat it to 400°C in a carbon dioxide atmosphere, keep it warm for 4 hours, and then raise the temperature to 600°C , heat preservation for 2h, after natural cooling, nitrogen-containing porous carbon is obtained, and its surface area is 610m 2 / g, total pore volume 0.403cm 3 / g, the average pore diameter is 1.1nm, the microporosity is 78%, and the nitrogen content is 7at% (atomic %).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com