Fabricating process of wood grain picture

A technology of making crafts and wood grains, which is applied in the field of making crafts of decorative paintings to achieve lifelike images and good visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

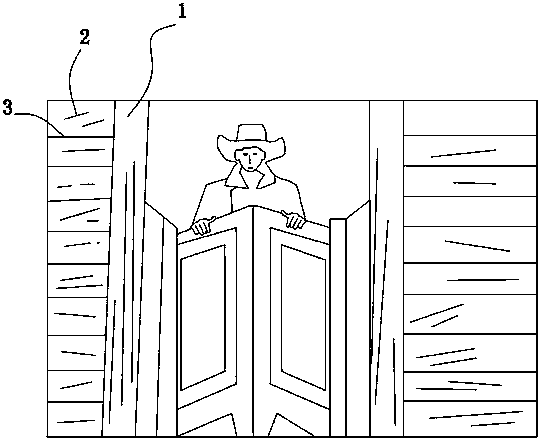

[0030] Embodiment: a kind of craft of woodgrain painting (see attached figure 2 attached image 3 attached Figure 4 ), (1) First cut the KT board according to the size of the decorative painting, and paste the KT board on the canvas through white latex. The KT board is a KT board with a white surface;

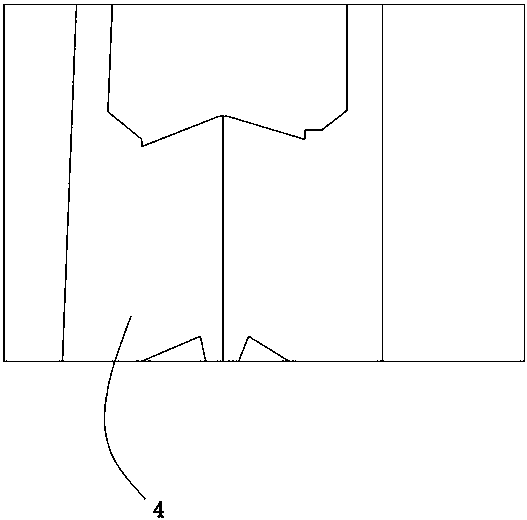

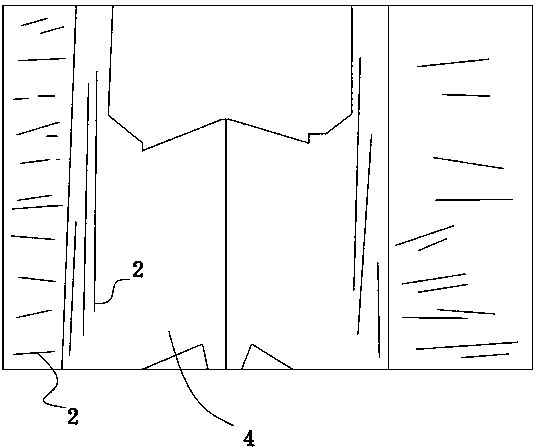

[0031] (2) After sticking firmly, outline the wood grain area 4 on the surface of the KT board according to the decorative painting. The grain area is scratched and scratched according to the direction of the strips. The direction of the scratches refers to the direction of the wooden grain 2 on the decorative painting. The end of the iron comb is processed to form an inclined surface. The inclined angle of the inclined surface is 35°. When the comb draws scratches, it is also inclined at 35°. The ends of the teeth of the iron comb on the inclined surface are on different planes. The density of the teeth on the inclined surface is 25 needles / square centimeter. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com