Dense medium continuous coal washing process and raw coal continuous crushing method

A technology of heavy medium and heavy medium cyclone is applied in the field of coal washing process, which can solve the problems of difficult cleaning of residues, low combustion efficiency, large coal transportation volume, etc., so as to reduce labor costs and transportation equipment costs, and reduce transportation capacity waste. , the effect of improving the efficiency of coal combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

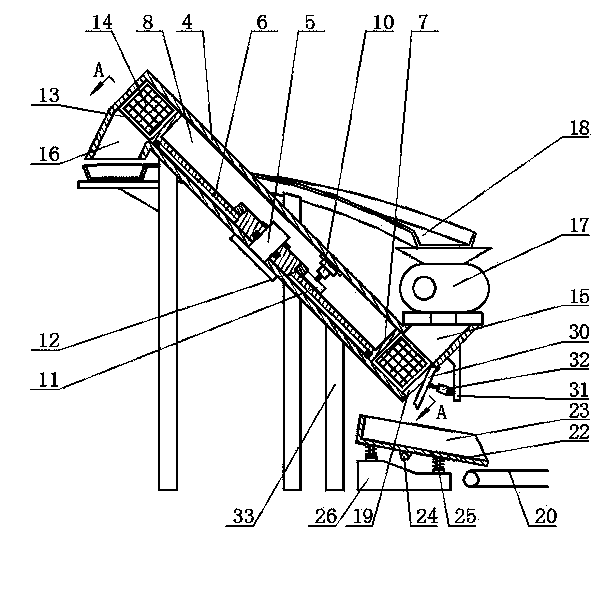

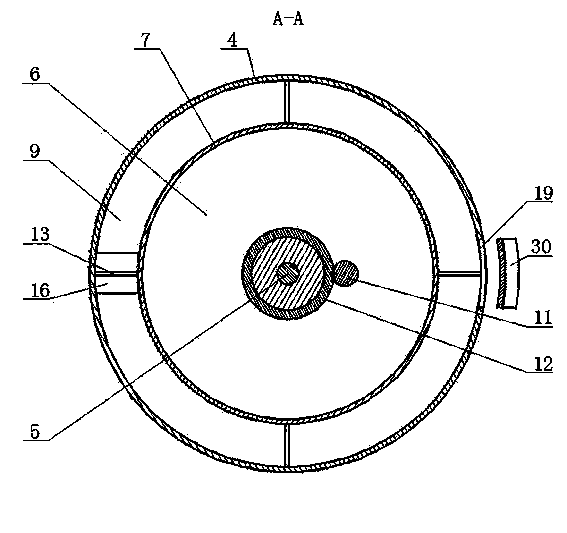

[0024] A dense medium continuous coal washing process described in the present invention comprises the following steps:

[0025] ①The above-mentioned coal washing medium powder is sent into the medium storage tank 28, and the coal washing medium powder is mixed with water in the medium storage tank 28 to form a dense medium suspension for use. The initial density of the dense medium suspension is 1.3 g / cm 3 -1.6 g / cm 3 ;

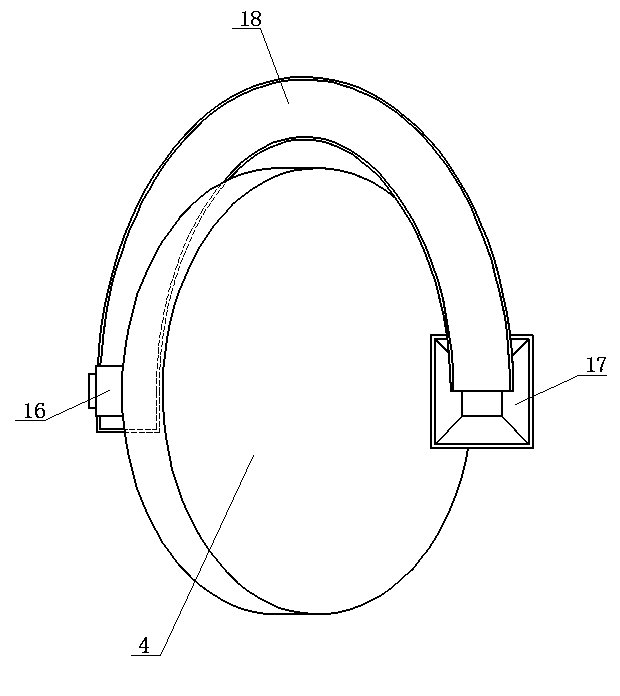

[0026] ②The raw coal is sent to the raw coal crusher 17 in the circulating coal crushing equipment 1 for crushing, and the crushed raw coal enters the separator;

[0027] ③The sorter selects the raw coal with a particle size smaller than 85mm after being crushed in step ②, and sends it to the raw coal storage tank 2 as a raw coal material for centralized storage, and sends the crushed raw coal with a particle size greater than or equal to 85mm back to the raw coal crusher 17 Broken again until the particle size is less than 85mm;

[0028] ④ Send the raw c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com