Reactor for preparing high-viscosity silicone oil emulsion

A reactor and emulsion technology, which is applied in the field of new silicone oil emulsion preparation, can solve the problems of product instability, failure to meet the requirements of good mixing of high-viscosity silicone oil system, and failure to meet the good emulsification of water agent and emulsifier, etc., to achieve emulsification uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

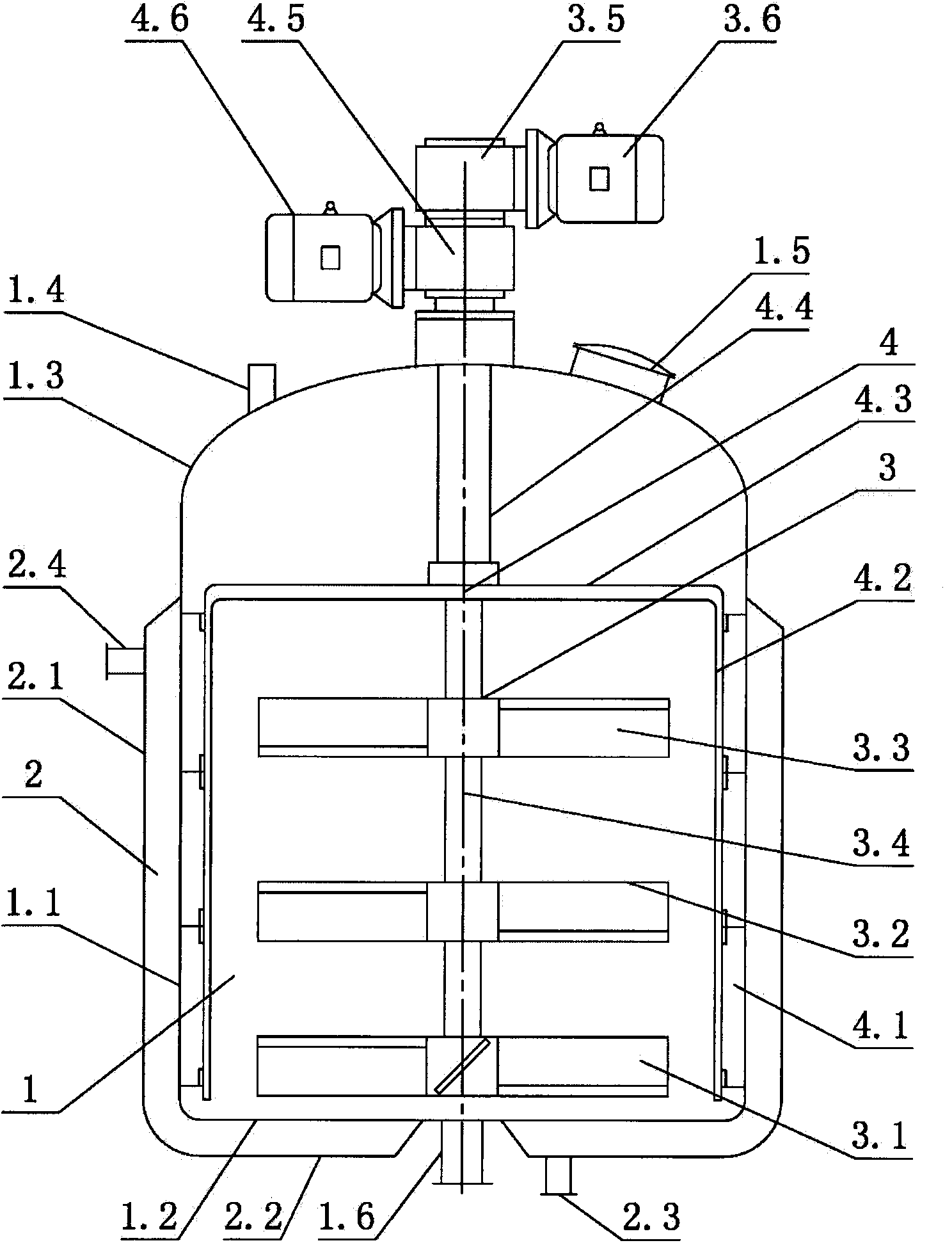

[0012] figure 1 Shown is a schematic diagram of the structure of a high-viscosity silicone oil emulsion reactor, which is mainly composed of a container body 1, a jacket 2, a main stirrer 3 and a scraper 4, and is characterized in that: the container body 1 is connected to the jacket 2 , the main agitator 3 and the scraper agitator 4 are arranged in the container main body 1, the main agitator shaft 3.4 is in the scraper agitator shaft 4.4, the two form a sleeve shaft, and the main agitator reducer 3.5 is arranged in the scraper agitator On the reducer 4.5.

[0013] The container body 1 includes a straight cylinder 1.1, a lower head 1.2, an upper head 1.3, a liquid inlet pipe 1.4, a manhole 1.5 and a discharge pipe 1.6. The straight body 1.1 is connected with the lower head 1.2 and the upper head 1.3 as a whole, the liquid inlet pipe 1.4 and the manhole 1.5 are installed on the upper head 1.2, and the discharge pipe 1.6 is installed at the bottom of the lower head 1.2. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com