Method for constructing tissue engineering cartilage

A technology of tissue engineering and construction methods, applied in medical science, prosthesis, etc., can solve problems such as abnormal and defective breathing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

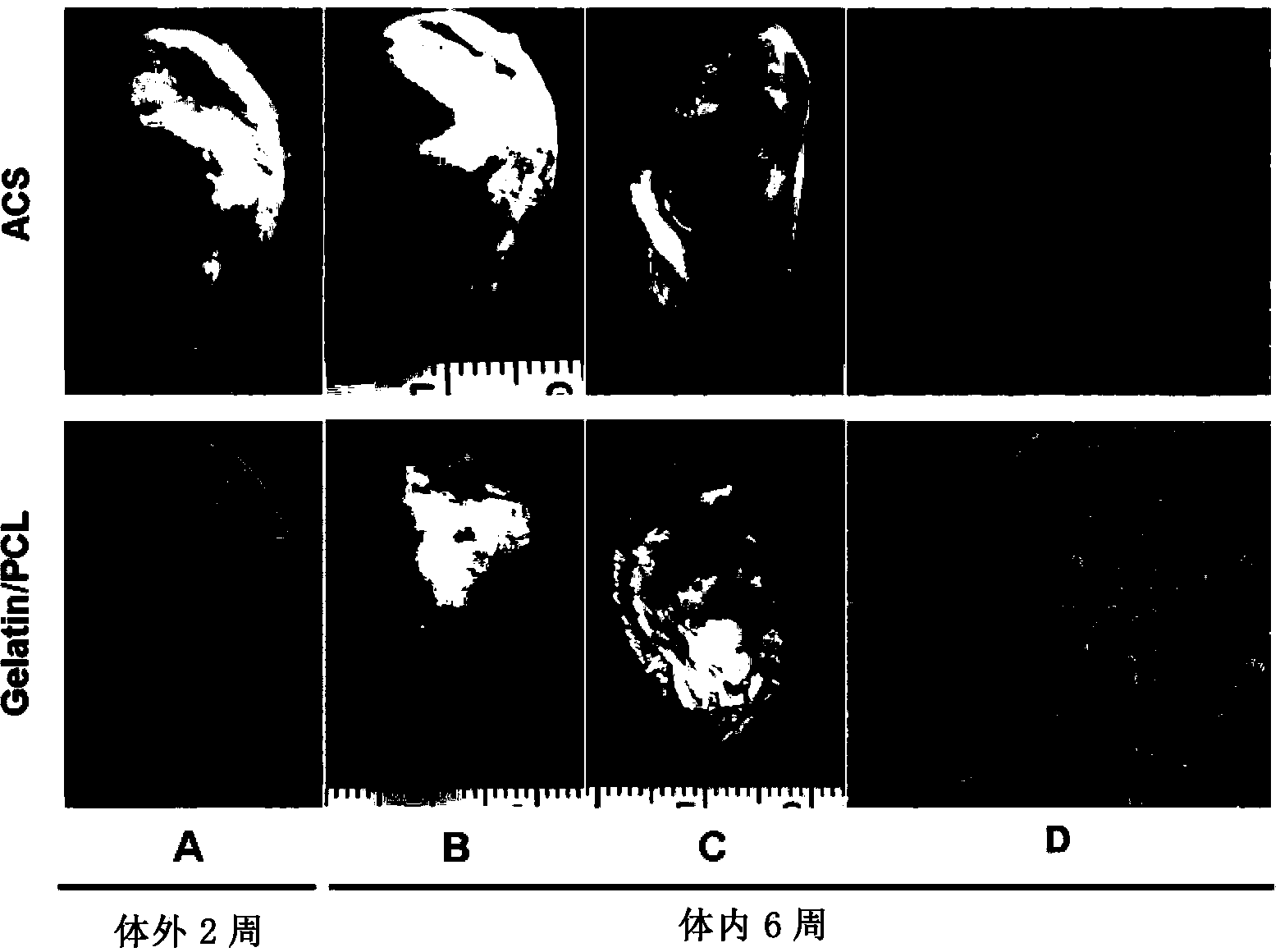

[0050] Materials and methods:

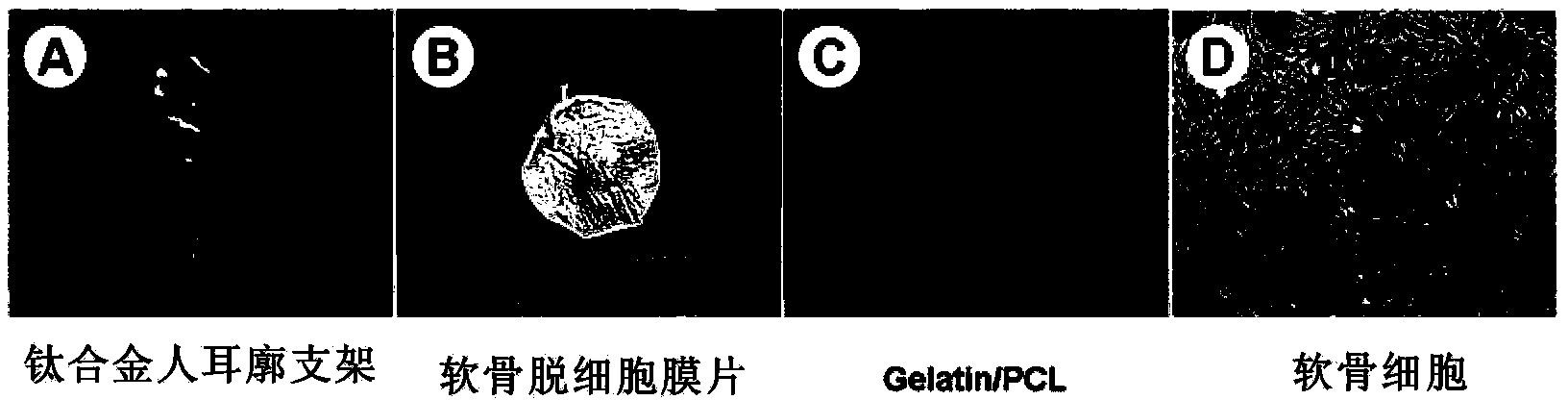

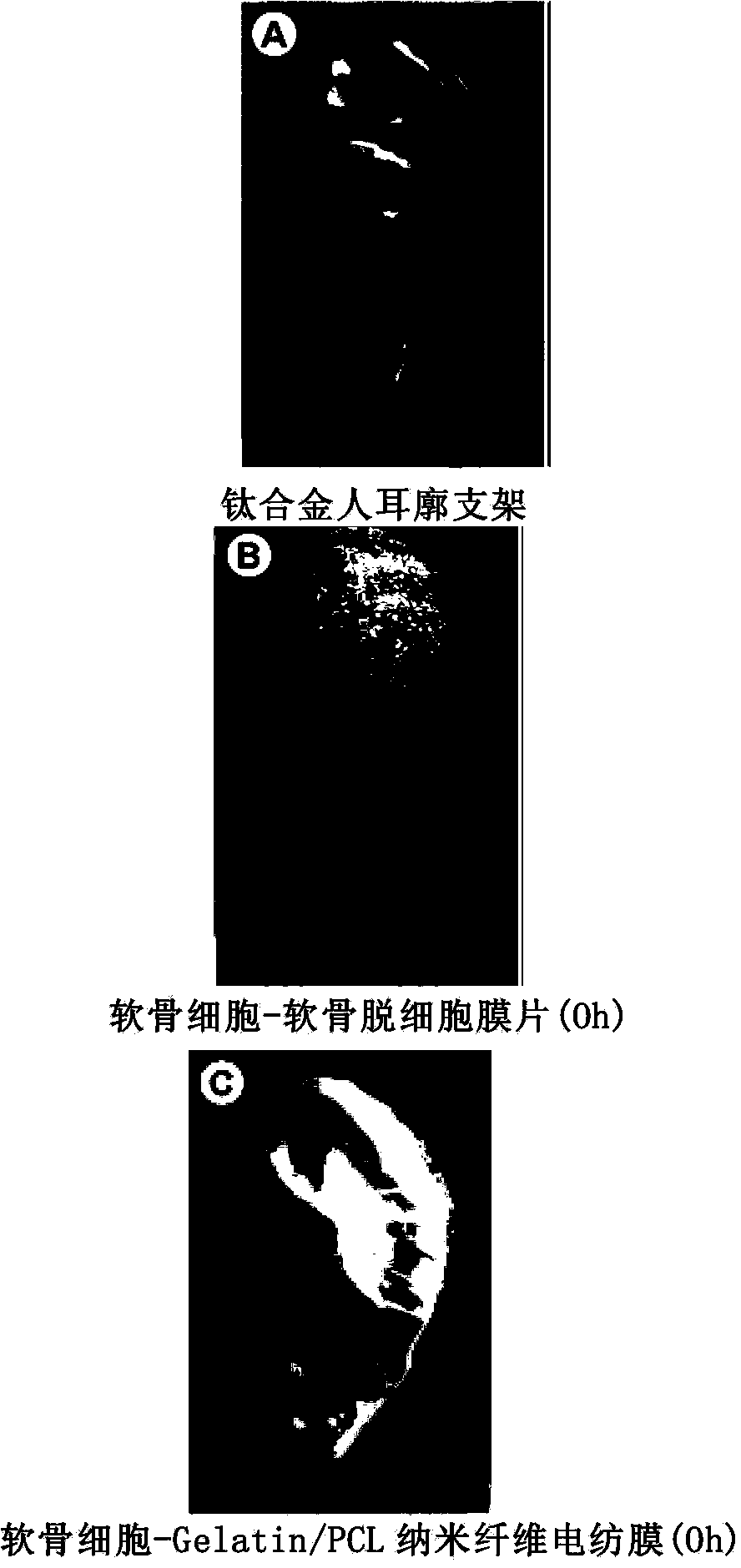

[0051] 1. Preparation of pinna-shaped titanium alloy stent

[0052] A normal adult ear was scanned by CT scan, and a miniature version (2:1) of the auricle mold was prepared by 3D printing technology based on the scan data, and a three-dimensional structure of the auricle-shaped bracket was pressed out of titanium alloy ( figure 1 A), 75% alcohol for disinfection.

[0053] 2. Preparation of cartilage acellular matrix membrane

[0054] Take fresh adult porcine auricular cartilage, cut it into a cylindrical shape with a diameter of 9 mm with a corneal trephine, and cut it into circular slices with a thickness of 10 μm with a cryostat, put it in 1% SDS (Shanghai Shenggong) solution, and shake it overnight on a shaker. Sections were rinsed several times with distilled water, and freeze-dried in a freeze dryer (Virtis, USA) for later use ( figure 1 B).

[0055] 3. Preparation of Gelatin / PCL nanofiber electrospun membrane

[0056] The ratio of Ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com