Vegetable plug seedling composite substrate and preparation method thereof

A technology of composite substrate and vegetable plug tray is applied in the fields of botanical equipment and methods, fertilizer mixture, soilless cultivation, etc., which can solve the problems of many ways of utilization, easy breeding of bacteria and flies, not suitable for large-scale vegetable seedling breeding, etc. Low incidence, achieving sustainable utilization, and maintaining the effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

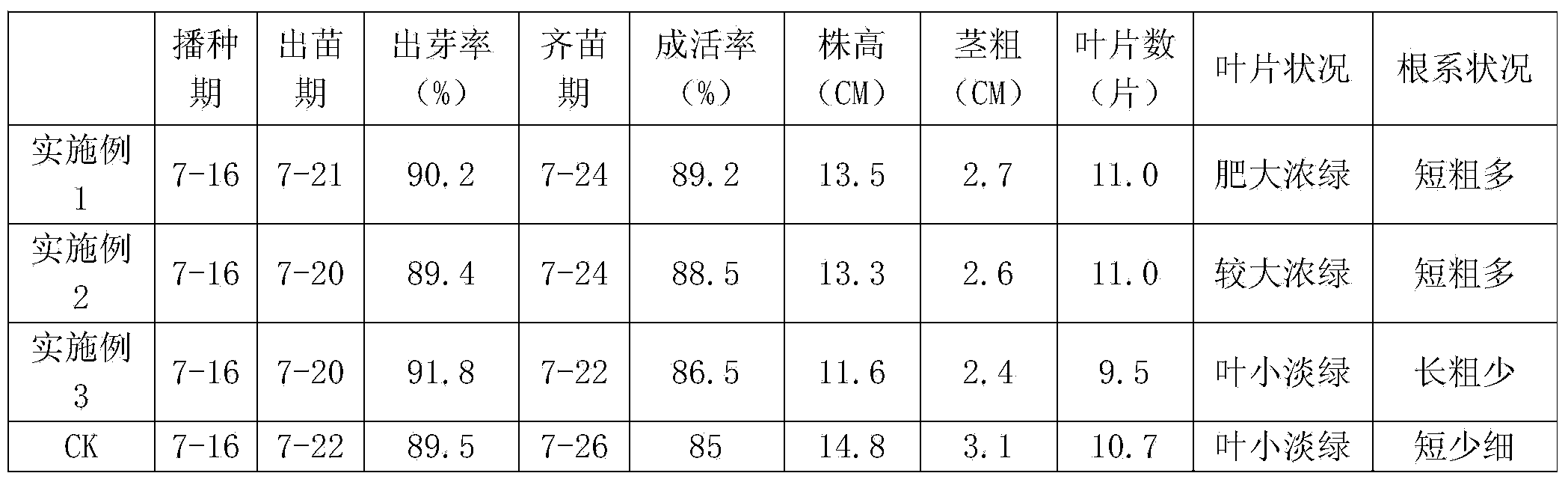

Examples

Embodiment 1

[0020] 1) After the chestnut shells are crushed, stacked, swelled, sprinkled with decomposing agent and covered with film, they are stacked and retting at 60-80°C until they are fully rotten, spread out and dried in the sun, and sieved through a 10-mesh sieve to obtain a particle size of 10-mesh granules to obtain chestnut shell composting products;

[0021] 2) After the chicken manure is covered with water and covered with a film, it is stacked and retting at 60-80°C until it is decomposed, spread out and dried in the sun to obtain decomposed chicken manure;

[0022] 3) Pulverize the discarded slag ash from a thermal power plant, pass through a 10-mesh sieve to sieve, and take a particle size of 10 mesh particles to obtain the slag ash;

[0023] 4) Take 80dm 3 Chestnut shell compost product 10dm 3 decomposed chicken manure and 10dm 3 The slag ash of the above-mentioned components is added into a matrix mixer, stirred and mixed evenly, and the composite matrix for vegetable...

Embodiment 2

[0026] 1) Crush chestnut shells and peanut shells, pile them up, swell with water, sprinkle decomposing agent and cover film, stack and retting at 60-80°C until fully rotted, spread them out and dry them in the sun, sieve them through a 5-mesh sieve, and take The particle size is 5 mesh particles, and the chestnut shell composting product is obtained;

[0027] 2) Concentrate chicken manure and pig manure, add water to cover the film, stack and retting at 60-80°C until decomposed, spread out and dry in the sun to obtain decomposed chicken manure and pig manure;

[0028] 3) Pulverize the discarded slag ash from the thermal power plant, pass through a 5-mesh sieve to sieve, and get the 5-mesh particles with a particle diameter to obtain the slag ash;

[0029] 4) Take 60dm 3 Chestnut shell and peanut shell compost products, 10dm 3 Decomposed chicken manure and pig manure and 30dm 3 The slag ash of the above-mentioned components is added into a matrix mixer, stirred and mixed ev...

Embodiment 3

[0032] 1) After the peanut shells are crushed, stacked, swelled, sprinkled with decomposing agent and covered with film, they are stacked and retting at 60-80°C until they are fully rotted, spread out and dried in the sun, and sieved through an 8-mesh sieve to obtain a particle size of 8-mesh granules, namely peanut shell composting products;

[0033] 2) After collecting the pig manure, adding water to cover the film, stacking and retting at 60-80°C until it becomes decomposed, spreading it out and drying it in the sun to obtain decomposed pig manure;

[0034] 3) Pulverize the discarded slag ash from the thermal power plant, pass through an 8-mesh sieve to sieve, and get the 8-mesh particles with a particle diameter to obtain the slag ash;

[0035] 4) Take 60dm 3 Chestnut shell compost products, 20dm 3 decomposed pig manure and 20dm 3 The slag ash and perlite are added into a matrix mixer for the above-mentioned components, stirred and mixed evenly, and the composite matrix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com