Carbon-silicon composite negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as instability and reduce the cycle performance of electrode materials, achieve easy operation, cycle stability, safety and pollution-free, and improve charging. Effects of Discharge Efficiency and Cycling Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

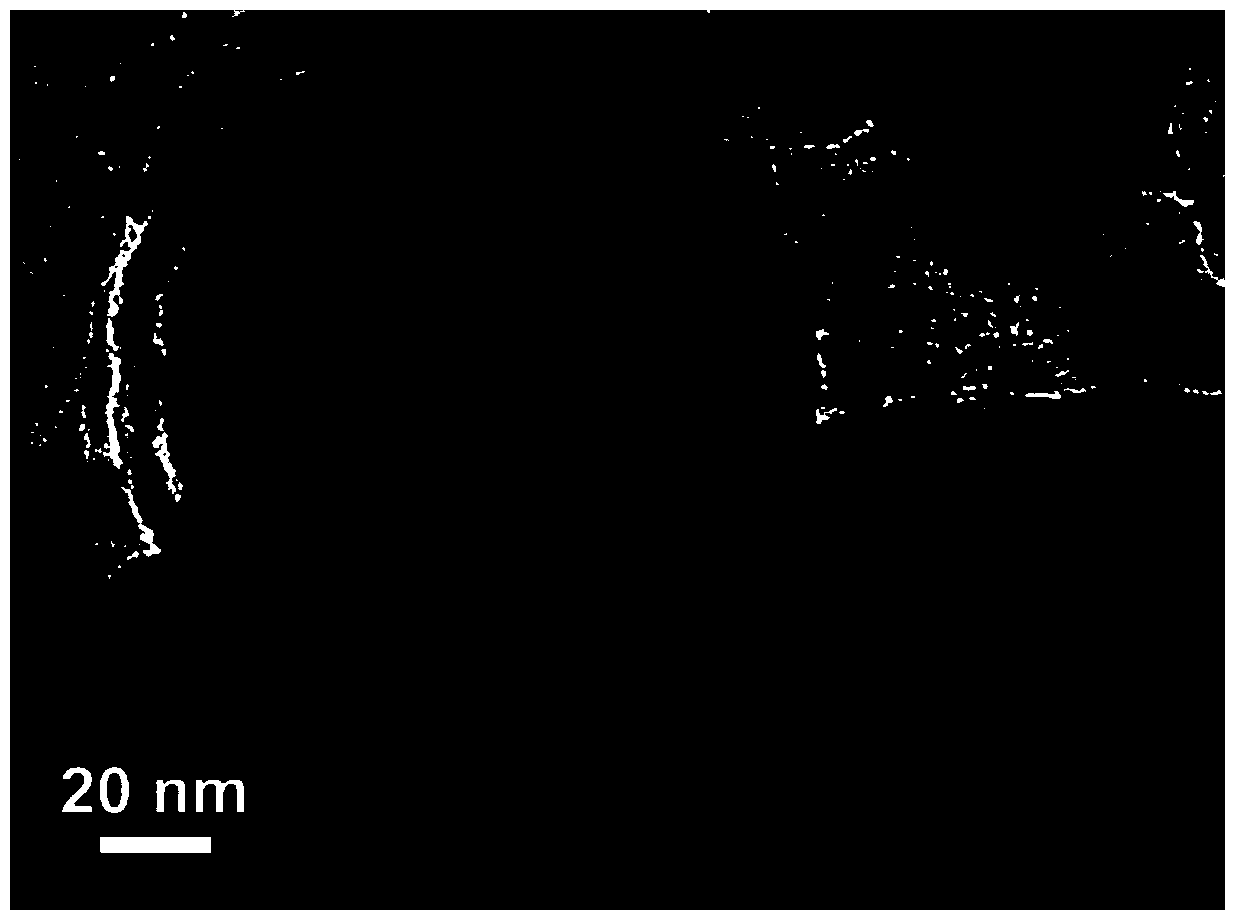

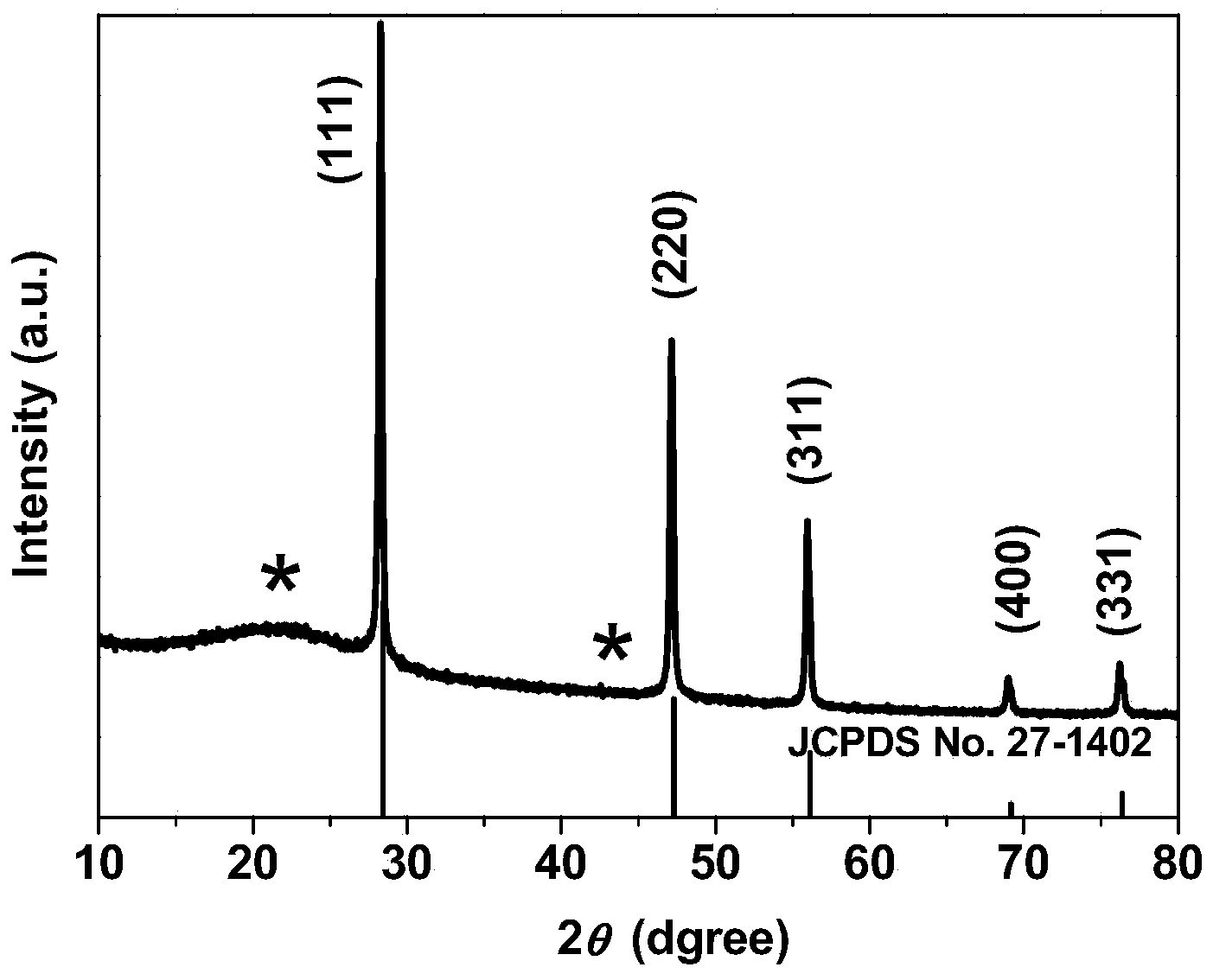

[0048] Embodiment 1: Silicon / carbon composite negative electrode material

[0049] Preparation of silicon / carbon composite anode materials with glucose as carbon source:

[0050] Weigh 3 grams of glucose and dissolve it in 30ml of deionized water, then weigh 0.3-3g of silicon powder with a particle size of 30-100nm and disperse (ultrasonic dispersion and magnetic stirring alternately) in the above-mentioned glucose aqueous solution to prepare a uniformly mixed system; Transfer the above homogeneous system to a polytetrafluoroethylene liner bottle, pass through a protective atmosphere to exclude oxygen, put the reaction kettle into an oven / oil bath with a set temperature of 110-180°C, take it out after reacting for 4-6 hours, and cool to room temperature , to obtain the hydrothermal product; the product obtained by hydrothermal carbonization was subjected to suction filtration, and distilled water and absolute ethanol were used as washing solvents in turn, and the precipitate o...

Embodiment 2

[0054] Example 2: Sulfur-doped silicon / carbon composite negative electrode material

[0055] Using 3,4-ethylenedioxythiophene as the sulfur source, p-toluenesulfonic acid as the dispersion medium, and glucose as the carbon source, the sulfur-doped silicon / carbon composite anode material was prepared:

[0056] Dissolve 0.58g p-toluenesulfonic acid in 30ml deionized water to obtain transparent liquid A, then weigh 0.1~0.3g 3,4-ethylenedioxythiophene dropwise into A, stir for 2 hours to obtain transparent and uniform solution B, weigh Dissolve 1 g of glucose in solution B, stir for 2 hours, weigh the catalyst ammonium persulfate (0.5 g) / ferric sulfate (2 mg) and add it into solution B and continue stirring to obtain a clear and transparent solution C; then weigh 0.3 g of particle size 30-100nm silicon powder, disperse (ultrasonic dispersion and magnetic stirring alternately) in solution C to prepare a uniformly mixed system D; transfer the above-mentioned uniform system D to a po...

Embodiment 3

[0060] Embodiment 3: silicon / porous carbon composite negative electrode material

[0061] Using F127 as a soft template / pore-forming agent and glucose as a carbon source to prepare silicon / porous carbon composite anode materials:

[0062] Weigh 0.28g of F127, dissolve it in 20ml of deionized water and stir overnight to obtain transparent liquid A, weigh 2.8-8.4g (at this time, the mass ratio of the soft template / pore-forming agent to the carbon source is 1:10-1:30 ) Glucose was dissolved in 10ml of deionized water and stirred to obtain a transparent solution B, solution B was dropped into solution A and stirred for 1 hour to obtain a transparent solution C, and then 0.3g of silicon powder with a particle size of 30-100nm was weighed and ultrasonically dispersed in solution C to prepare A uniformly mixed system D was obtained; transfer the above homogeneous system D to a polytetrafluoroethylene liner bottle, pass through a protective atmosphere to exclude oxygen, put the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com