Turnout production plan execution system and working method

A technology of production planning and execution system, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problem of restricting production, the difficulty of plan managers to grasp the implementation of production plan in real time, and the inability to record the process data of product processing, etc. problem, to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

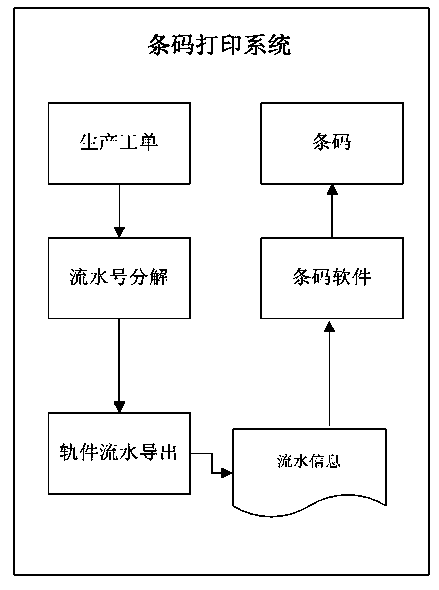

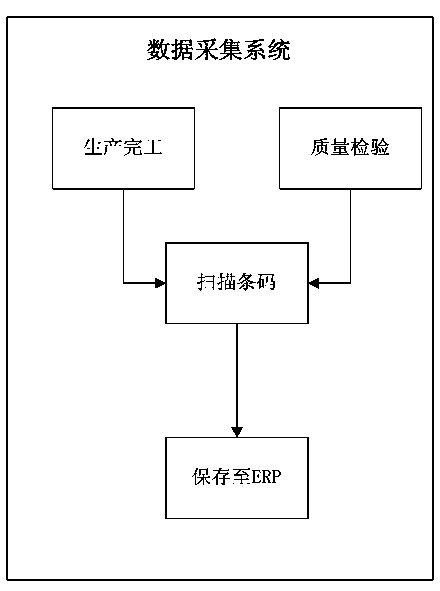

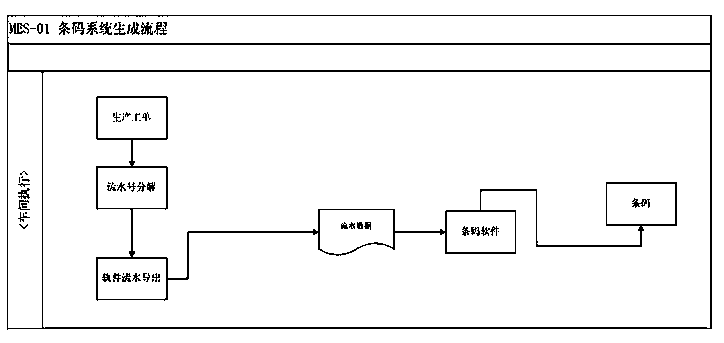

[0016] Embodiment 1: with reference to attached Figure 1-5 . A production plan execution system for a turnout, which is characterized in that it is composed of a barcode printing device, a terminal computer, a sub-computer, a turnout processing subsystem, a barcode data acquisition device and a local area network. A barcode is posted on each piece, and the serial number of each rail piece is recorded in the barcode. The production task is directly sent to the terminal computer of each equipment through the sub-computer and the local area network, and the terminal computer outputs processing instructions to the turnout processing subsystem. After the turnout processing subsystem completes the processing according to the terminal computer output processing instructions, the barcode data acquisition device realizes the production report by scanning the serial number on the rail, and at the same time, the quality inspector scans the barcode through the barcode data acquisition de...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, a working method of the turnout production plan execution system, (1) calculate the start date of the production task through the MRP system; (2) develop the serial number decomposition program, and the barcode printing device for each One rail piece generates a serial number, and the serial number corresponds to each processed rail piece one by one; (3) The connection between the computer information flow and the physical flow is realized through the barcode data acquisition device; (4) The terminal computer calculates the accuracy to the turnout The daily shift plan of the processing subsystem; (5) The sub-computer terminal is installed on the workshop equipment, and the production plan is displayed on the sub-computer terminal in real time. After processing, various processing data can be collected through the barcode data acquisition device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com