Quick-frozen food whole-process quality tracing method

A quick-frozen food, full-process technology, applied in logistics, data processing applications, instruments, etc., can solve the problems of asymmetric information between manufacturers and consumers, adversely affecting the quality of the manufacturer, and affecting the image of the manufacturer, and achieve the collection of finished product information. The effect of more intelligent, transparent traceability and convenient access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A kind of quick-frozen food whole process quality traceability method of the present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

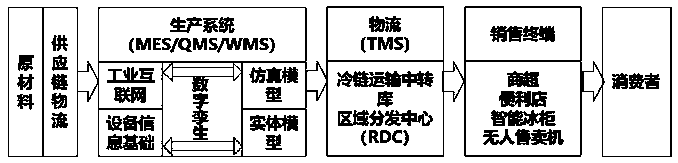

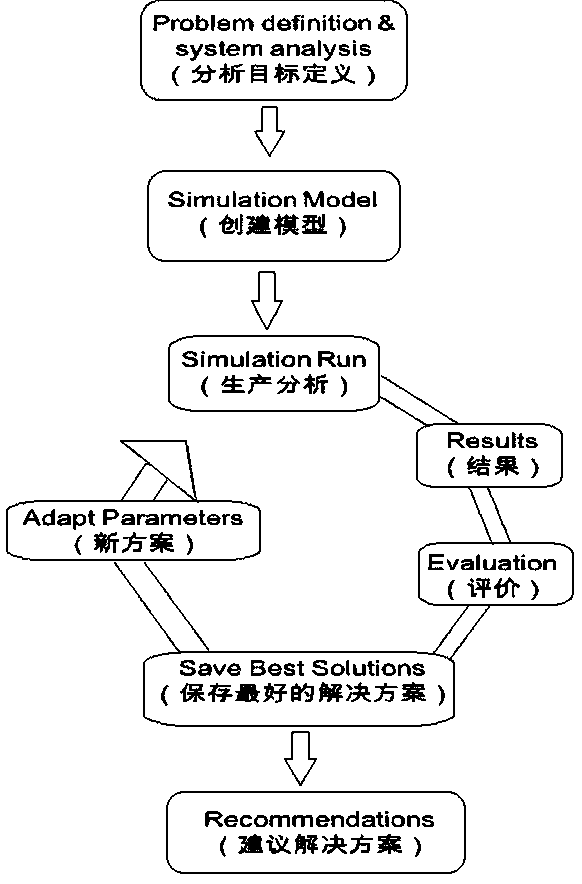

[0036] In the actual production process, the processing technology of quick-frozen food (take dumplings as an example), and the processing technology of quick-frozen food such as figure 1 As shown in the figure, it mainly includes several major links such as filling preparation, dough preparation, molding, quick freezing, packaging, storage, etc. The process flow chart is shown in the figure.

[0037] In the process of quick-frozen food processing, meat processing, vegetable processing, quick-freezing, packaging, and storage are the most important and key control links.

[0038] 1. Meat processing; the following inspections are required before the raw materials are used: a. Microbiological testing; b. Sensory inspection; c. Taste identification; d. Thermometer measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com