Bamboo-willow scrimber manufacturing process

A manufacturing process and recombined wood technology, applied in the field of bamboo and willow recombined wood manufacturing technology, can solve the problems of rare recombined wood products, long production cycle, unstable product performance, etc., to promote extensive planting, increase demand, and increase raw materials Effect of category selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

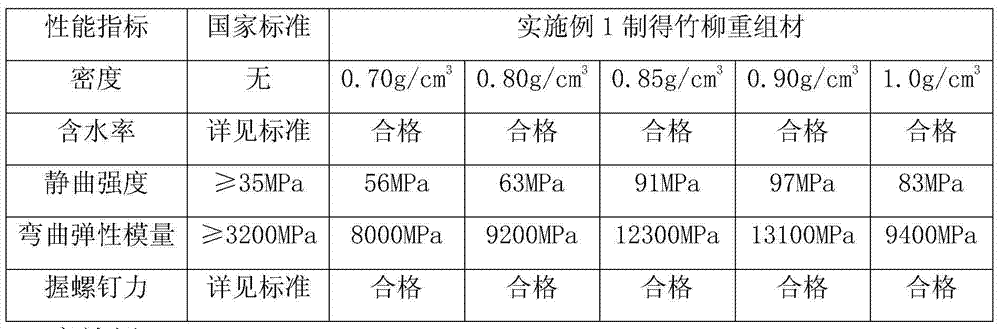

Embodiment 1

[0033]The bamboo willow recombined wood manufacturing process of the present embodiment comprises the following steps:

[0034] The first step is to collect bamboo and willow branches and small-diameter grades. After removing the bark, send them to the wood longitudinal rolling and cutting machine to make wood bundles, and dry them at 102°C until the moisture content is 5%;

[0035] The second step is to immerse it in a water-soluble phenolic resin adhesive with a solid content of 24%, and the immersion time is 15s, then first dry the glued wood bundles to a moisture content of 20%, and then place the wood bundles in Dry at 40°C-50°C for 40-70min, so that the moisture content of wood bundles is 9-11%;

[0036] The third step is to pave evenly into slabs along the direction of the grain, and bind the bundles after directional paving;

[0037] The fourth step is to send the paved slab into the press for cold pressing and shaping for 1min, and the cold pressing pressure is 2.0MP...

Embodiment 2

[0042] The bamboo willow recombined wood manufacturing process of the present embodiment comprises the following steps:

[0043] The first step is to collect bamboo and willow branches and small-diameter grades, remove the bark, and send them to the longitudinal wood rolling and cutting machine to make wood bundles, and dry them at 115°C until the moisture content is 4%;

[0044] The second step is to immerse it in a water-soluble phenolic resin adhesive with a solid content of 23.5%, and the immersion time is 25s, then first dry the glued wood bundles to a moisture content of 19%, and then place the wood bundles in Dry at 45°C for 60 minutes to make the moisture content of wood bundles 10%;

[0045] The third step is to pave evenly into slabs along the direction of the grain, and bind the bundles after directional paving;

[0046] The fourth step is to send the paved slab into the press for cold pressing and shaping for 1min, and the cold pressing pressure is 2.0MPa;

[004...

Embodiment 3

[0051] The bamboo willow recombined wood manufacturing process of the present embodiment comprises the following steps:

[0052] The first step is to collect bamboo and willow branches and small-diameter grades. After removing the bark, send them to the wood longitudinal rolling and cutting machine to make wood bundles, and dry them at 108°C until the moisture content is 7%;

[0053] The second step is to immerse it in a water-soluble phenolic resin adhesive with a solid content of 22%, and the immersion time is 20s, and then naturally dry the glued wood bundles to a moisture content of 18%;

[0054] The third step is to pave evenly into slabs along the direction of the grain, and bind the bundles after directional paving;

[0055] The fourth step is to send the paved slab into the press for cold pressing and shaping for 3 minutes, and the cold pressing pressure is 3.0MPa;

[0056] Step 5: Put it in a flat-panel hot press for hot-press curing. The hot-press time is 55s / mm, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com