Two-component hydrolyzable antifouling coating composition, antifouling coating film, and method for producing an antifouling substrate

An antifouling coating, two-component technology, applied in antifouling/underwater coatings, polyester coatings, devices for coating liquids on surfaces, etc., to achieve long-term good antifouling properties, excellent antifouling properties, and excellent mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

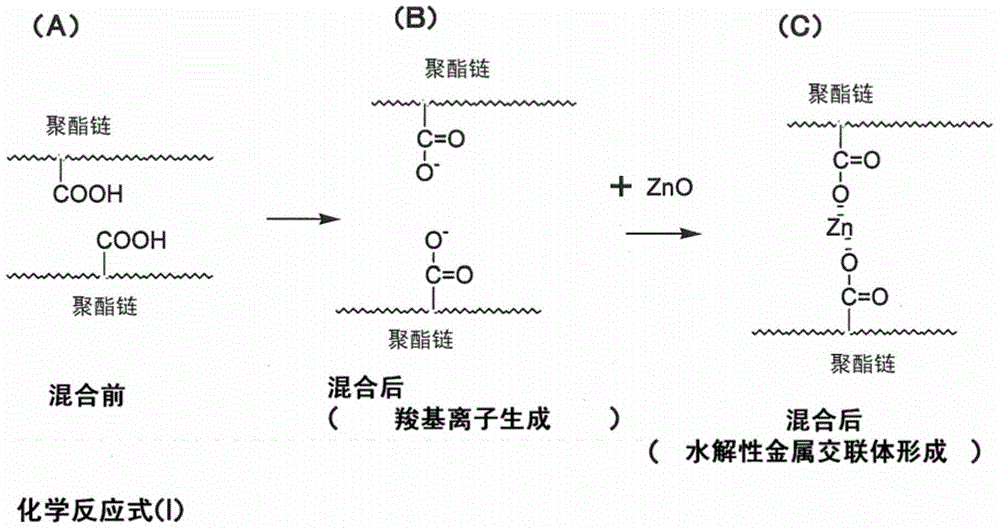

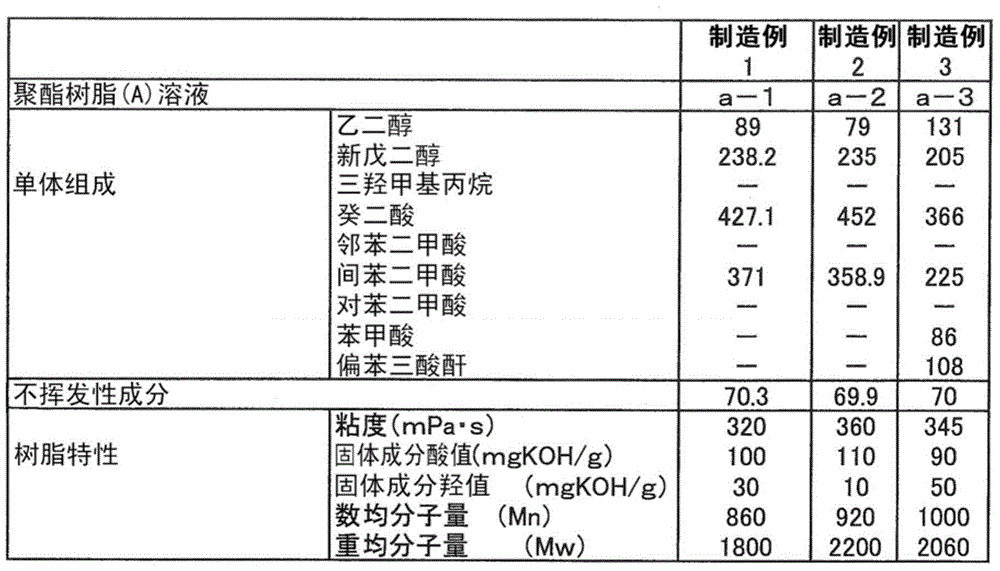

[0222] [Manufacture Example 1: Manufacture of Polyester Resin Solution (a-1)]

[0223] 371.0 parts of isophthalic acid, 427.1 parts of sebacic acid, 238.2 parts of neopentyl glycol and 89.0 parts of ethylene glycol were mixed in a 2L four-necked flask, and reacted at 220° C. for 5 hours in the presence of nitrogen (esterification reaction) . During the reaction, the generated water was removed by reflux dehydration, the acid value was measured by the KOH titration method, and the hydroxyl value was measured by the acetylation method. The acid value of the solid component in the reaction solution reached 100mgKOH / g, and the hydroxyl value of the solid component reached The reaction was stopped at 30mgKOH / g. After cooling the reaction solution, it was diluted with methyl isobutyl ketone to obtain a resin composition (polyester resin solution (a-1)) having an acid value of 70 mgKOH / g, a hydroxyl value of 21 mgKOH / g, and a solid content of 70.3%. As shown in Table 1, the solid con...

manufacture example 2

[0224] [Manufacture Example 2: Manufacture of Polyester Resin Solution (a-2)]

[0225] Except changing the consumption of raw materials into the amount shown in Table 1, obtain acid value 157.4mgKOH / g, hydroxyl value 14.3mgKOH / g, solid content 69.9% resin composition (polyester resin solution ( a-2)) Various physical properties were evaluated in the same manner as in Production Example 1.

[0226] As shown in Table 1, the acid value of the solid content of the above resin composition is 110 mgKOH / g, the hydroxyl value of the solid content is 10 mgKOH / g, and the viscosity (25° C.) of the above resin composition is 360 mPa·s. The above resin composition contains a polyester resin having a weight average molecular weight of 2200 and a number average molecular weight of 920.

manufacture example 3

[0227] [Production Example 3: Production of Polyester Resin Solution (a-3)]

[0228] Mix 225.0 parts of isophthalic acid, 366.0 parts of sebacic acid, 205.0 parts of neopentyl glycol, 131.0 parts of ethylene glycol and 86.0 parts of benzoic acid in a 2L four-necked flask, and react at 220°C for 6 hours in the presence of nitrogen (esterification reaction). Remove the generated water by reflux dehydration, measure the acid value by KOH titration method, and measure the hydroxyl value by acetylation method. The acid value of the solid component in the reaction liquid reaches 43mgKOH / g, and the hydroxyl value of the solid component reaches 115mgKOH / g. stop responding. Then cool to 170° C., add 108.0 parts by weight of trimellitic anhydride, keep warm for 2 hours to carry out addition reaction, and stop the reaction when the acid value of the solid component in the reaction liquid reaches 90 mgKOH / g, and the hydroxyl value of the solid component reaches 60 mgKOH / g. After cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com