Slide fastener

A technology for zippers and zipper tapes, applied in the field of zippers, which can solve problems such as peeling of sheet parts, high manufacturing costs of zippers, inability to engage and disengage zipper elements, etc., and achieve the effect of improving liquid tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

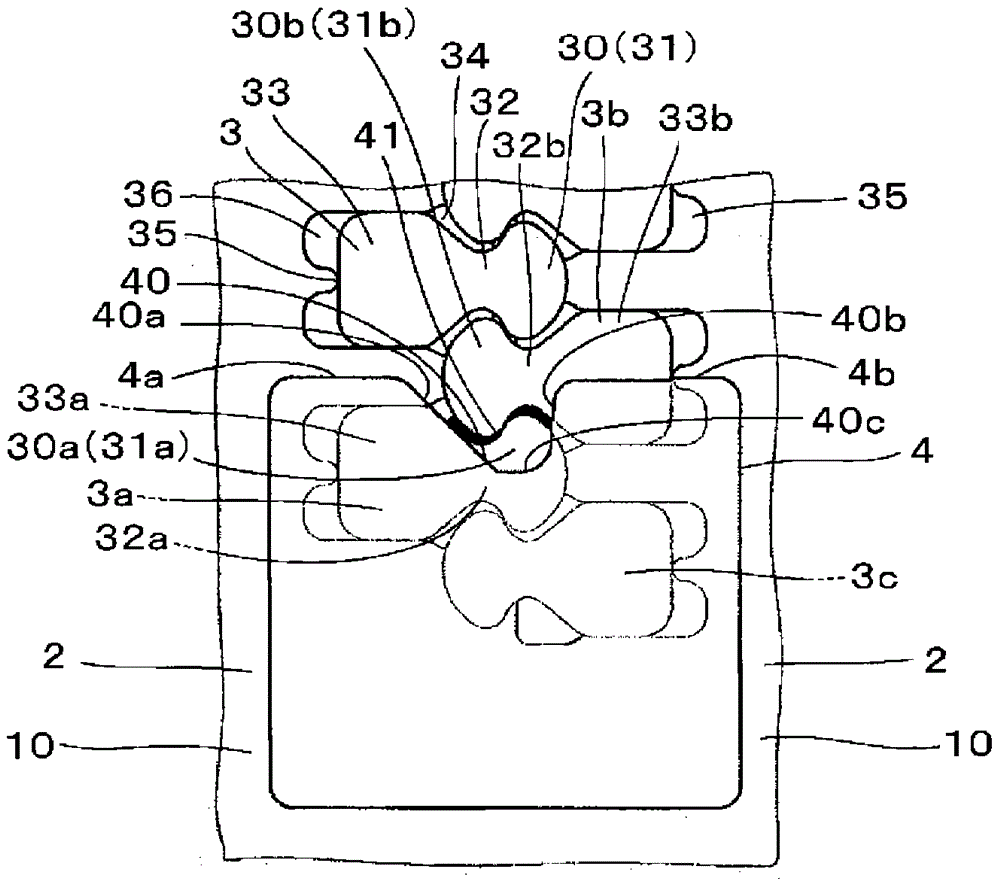

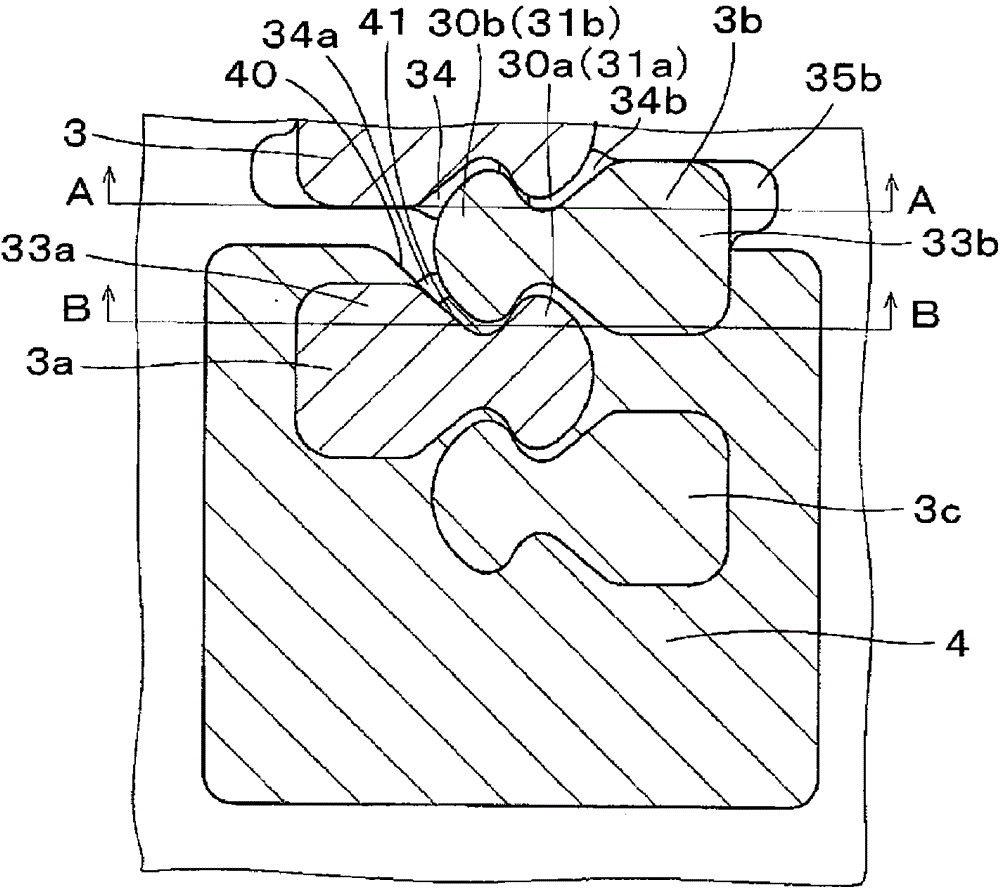

[0032] Embodiments of the present invention will be described with reference to the drawings. In the following description of the drawings, the same or similar reference numerals are attached to the same or similar parts. In addition, the embodiment shown below is only an illustration of the structure which actualized the technical thought of this invention, and the specific structure of the technical thought of this invention is not limited to the following content.

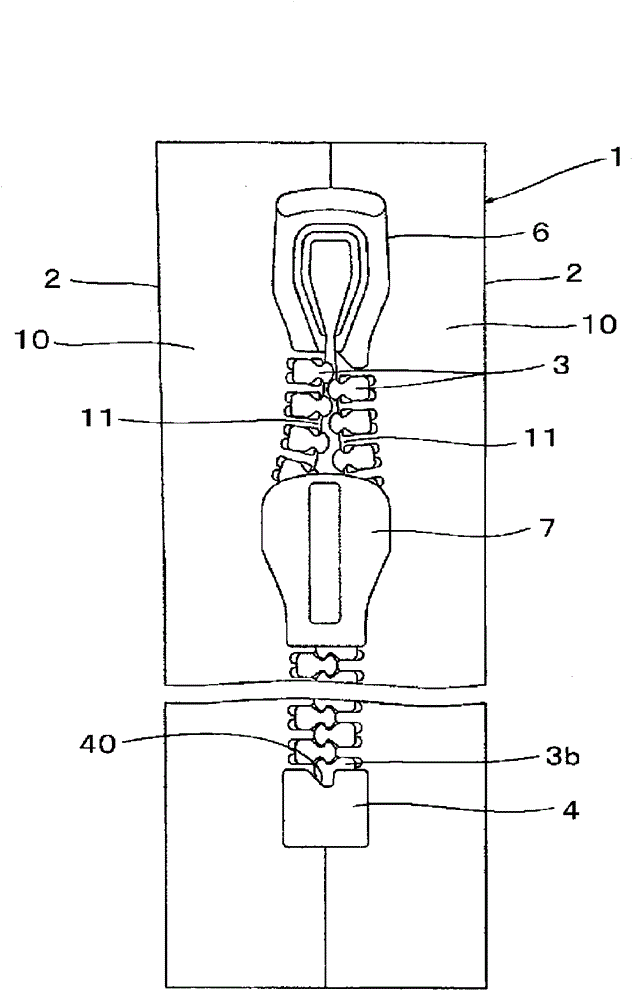

[0033] figure 1 It is a plan view explanatory drawing which cut|disconnected and showed the whole structure example of the slide fastener 1 which concerns on one Embodiment of this invention along the longitudinal direction (paper top-bottom direction). like figure 1 As shown, the zipper 1 includes: a zipper string 2, which has a plurality of zipper elements 3 arranged in a row along the opposite edge portions 11, 11 of a pair of left and right zipper tapes 10, 10; and a slider 7, which It is used to engage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com