A rebound plug assembly of an automatic feeding device and a washing machine having the same

An automatic feeding and plugging technology, which is applied to other washing machines, washing devices, household appliances, etc., can solve the problems of discontinuous pumping and leakage of detergent boxes, so as to avoid discontinuous pumping, reduce the amount of leakage, The effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

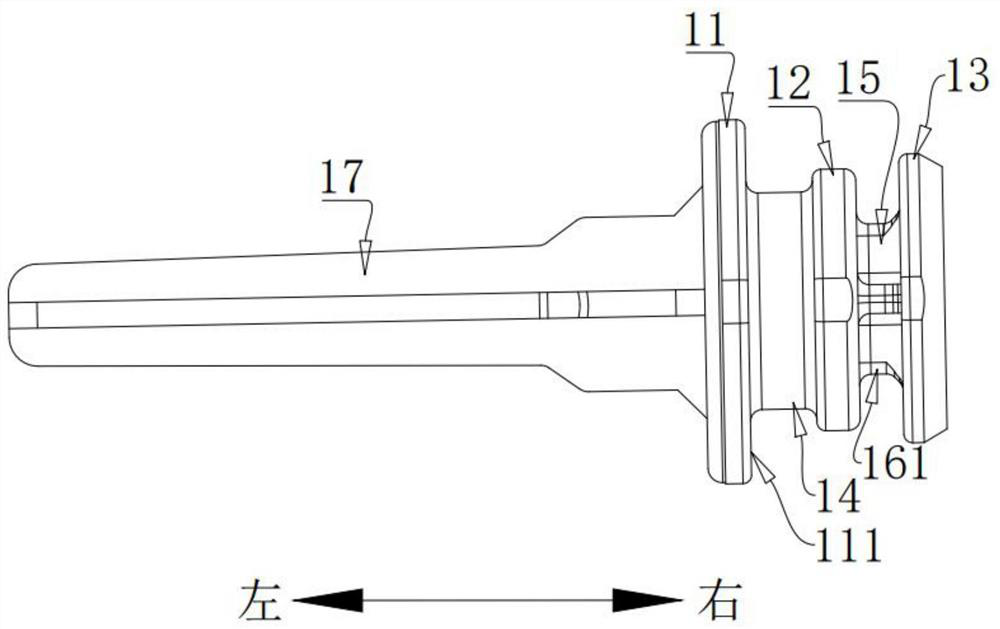

[0039] In the present invention, a spring-back assembly is provided between the liquid outlet pipe of the liquid storage box and the liquid suction pipe of the liquid suction pump. The sealing tapered surface of the liquid box is in close contact, and the liquid outlet pipe of the liquid storage box is closed to avoid liquid leakage; the end of the rebound plug is provided with a confluence cavity, when the suction pipe of the liquid pump is connected to the liquid outlet pipe of the liquid storage box At this time, under the action of the liquid pump, the detergent in the liquid storage box first enters the confluence cavity, and then enters the liquid pump to avoid discontinuous liquid pumping; the rebound plug shortens the distance between the sealing ring and the sealing surface, making the The rebound time of the spring is reduced, reducing the amount of fluid leakage when the reservoir pops out.

[0040]

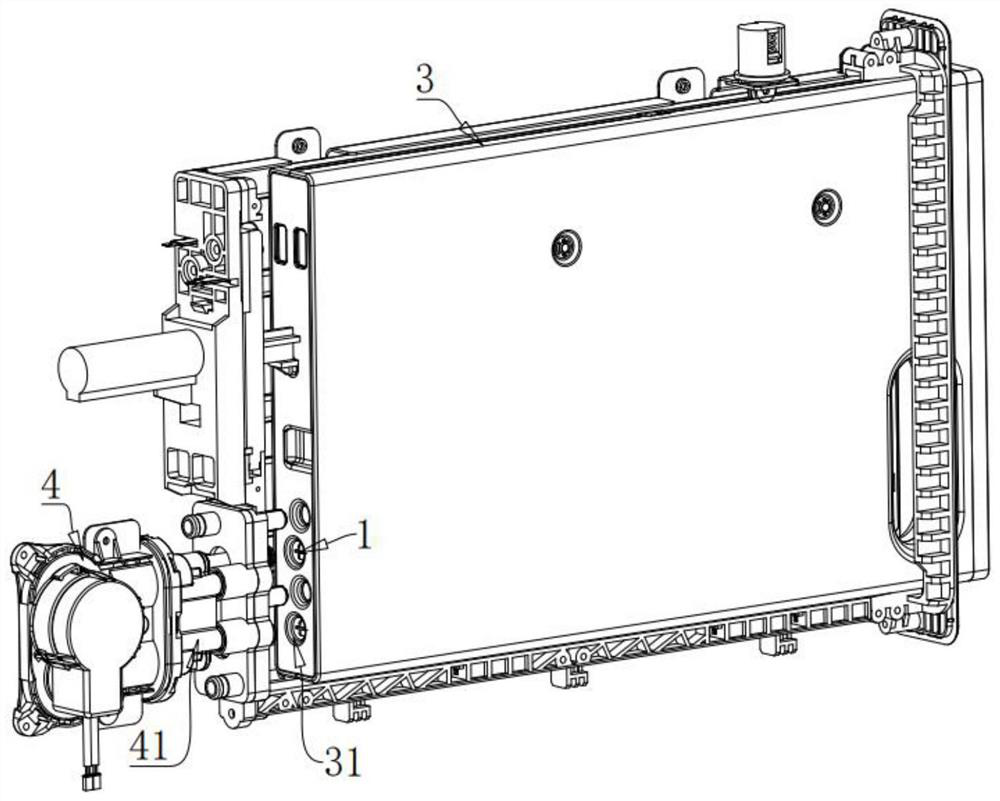

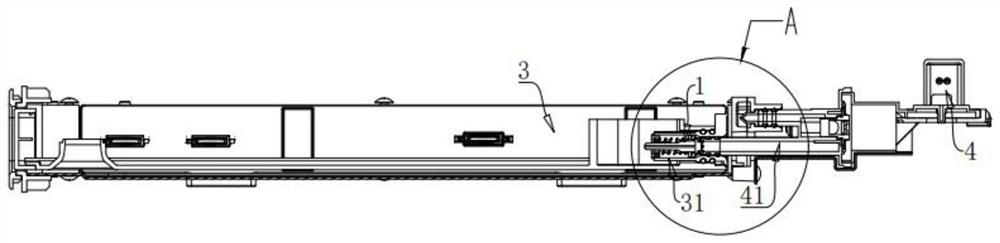

[0041] Such as Figure 1a with Figure 1b As shown, the reboun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com