Method for manufacturing high-refractive-index silicon nitride antireflection film

A silicon nitride reduction and high refractive index technology, applied in the field of solar cells, can solve the problems of reduced open-circuit voltage and short-circuit current, and reduced conversion rate of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

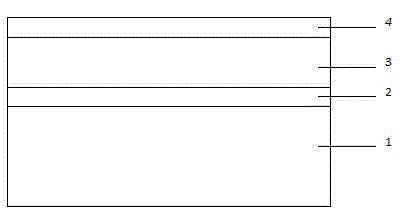

Image

Examples

Embodiment 1

[0014] (1) Deposit the crystalline silicon wafer after cleaning, texturing, diffusion and etching by tubular PECVD to obtain the first layer of high refractive index silicon nitride anti-reflection film. The PECVD parameters are set as: ammonia gas flow rate 6.5slm, silane flow rate 750sccm , pressure 1600mTorr, RF power 7300w, switch time 5:50ms, time 80s;

[0015] (2) Deposit the anti-reflection film obtained after step (1) by tubular PECVD again to obtain the second layer of high-refractive-index silicon nitride anti-reflection film. The PECVD parameters are set to: ammonia gas flow rate 4.8slm, silane flow rate 850sccm, pressure 1600mTorr, RF power 7300w, switch time 5:50ms, time 280s;

[0016] (3) Deposit the anti-reflection film obtained after step (2) by tubular PECVD again to obtain the third layer of low-refractive-index silicon nitride anti-reflection film. The PECVD parameters are set to: ammonia gas flow rate 6.5slm, silane flow rate 650sccm, pressure 1600mTorr, T...

Embodiment 2

[0019] (1) Deposit the crystalline silicon wafer after cleaning, texturing, diffusion and etching by tubular PECVD to obtain the first layer of high refractive index silicon nitride anti-reflection coating. The PECVD parameters are set to: ammonia gas flow rate 7 slm, silane flow rate 800 sccm , pressure 1700mTorr, RF power 7000w, switching time 5:50ms, time 100s;

[0020] (2) Deposit the anti-reflection film obtained after step (1) by tubular PECVD again to obtain the second layer of high-refractive-index silicon nitride anti-reflection film. The PECVD parameters are set to: ammonia gas flow rate 5.2slm, silane flow rate 900sccm, pressure 1700mTorr, RF power 7000w, switch time 5:50ms, time 300s;

[0021] (3) Deposit the anti-reflection film obtained after the completion of step (2) by tubular PECVD again to obtain the third layer of low-refractive index silicon nitride anti-reflection film. The PECVD parameters are set as: ammonia gas flow rate 6.8 slm, silane flow rate 680 s...

Embodiment 3

[0024] (1) Deposit the crystalline silicon wafer after cleaning, texturing, diffusion and etching by tubular PECVD to obtain the first layer of high refractive index silicon nitride anti-reflection film. The PECVD parameters are set as: ammonia gas flow rate 7.2slm, silane flow rate 850sccm , pressure 1800mTorr, RF power 6500w, switching time 5:50ms, time 130s;

[0025] (2) Deposit the anti-reflection film obtained after step (1) by tubular PECVD again to obtain the second layer of high refractive index silicon nitride anti-reflection film. The PECVD parameters are set to: ammonia gas flow rate 5.5slm, silane flow rate 950sccm, pressure 1800mTorr, RF power 6500w, switch time 5:50ms, time 330s;

[0026] (3) Deposit the anti-reflection film obtained after the completion of step (2) by tubular PECVD again to obtain the third layer of low-refractive index silicon nitride anti-reflection film. The PECVD parameters are set to: ammonia gas flow rate 7.5slm, silane flow rate 750sccm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com