Double-85 anti-PID polycrystalline solar cell manufacturing process

A technology for solar cells and manufacturing processes, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve problems such as the power drop of cells and modules, and achieve the effect of extending the life of modules, good product performance, and convenient inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

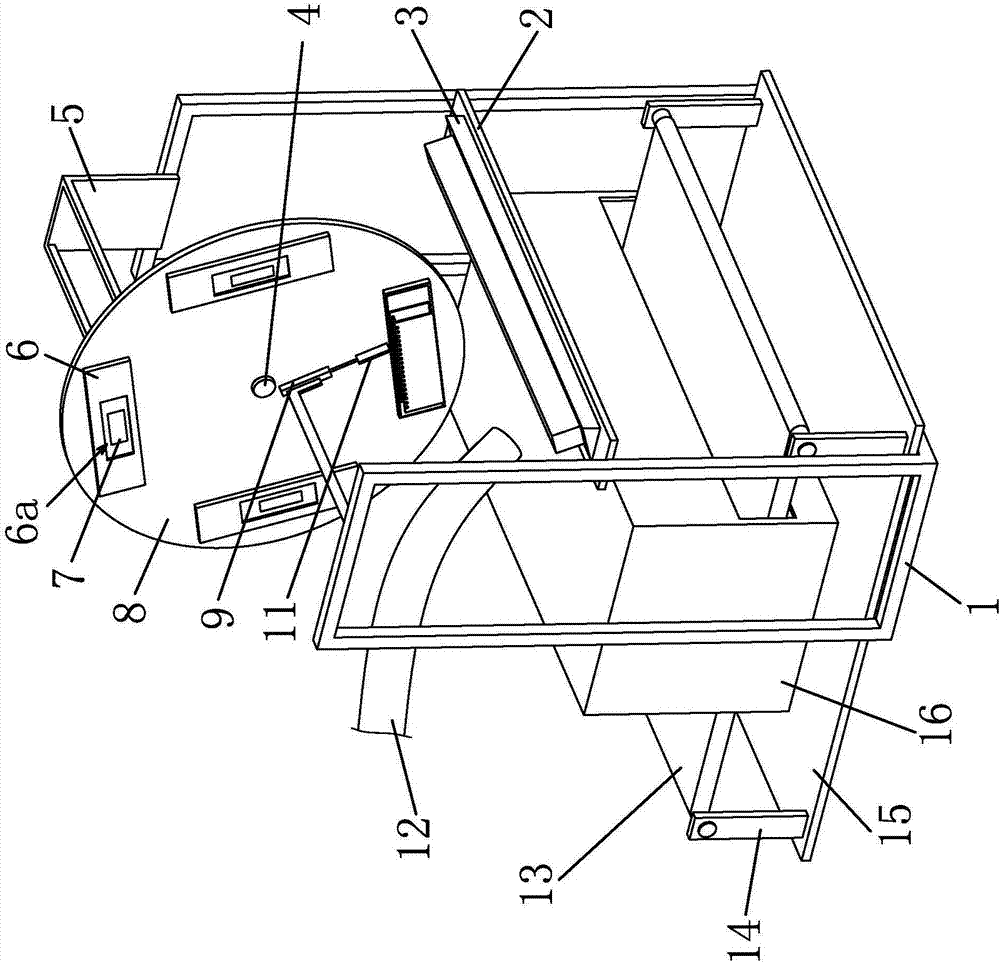

[0072] The manufacturing process of the double 85 anti-PID polycrystalline solar cells comprises the following steps:

[0073] a. The crystalline silicon wafer after cleaning, diffusion, and etching will generate a layer of 1nm SiO on the surface of the crystalline silicon wafer through an ozone generator 2 Oxide film;

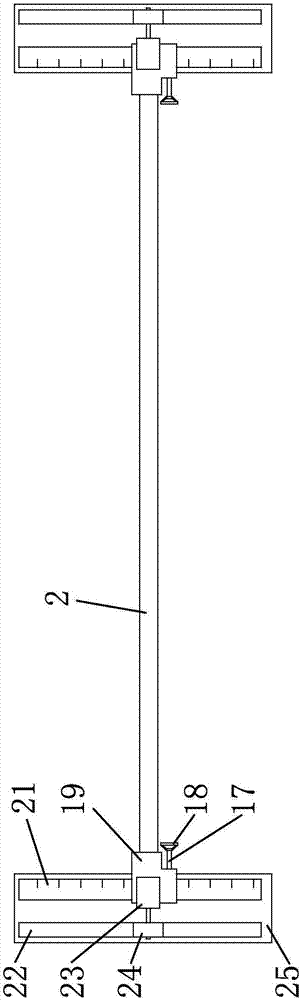

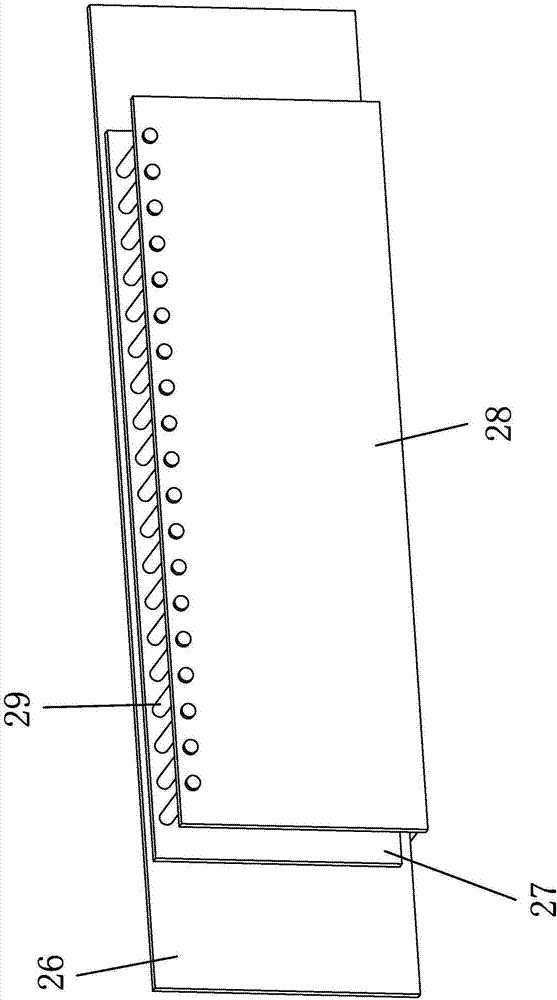

[0074] b. Put the crystalline silicon wafer completed in step a on the graphite boat through the loading and unloading system, and put it into the tubular PECVD for pre-deposition. The PECVD parameters are set as: ammonia gas flow rate 4.5-5.0slm, radio frequency power 5000-6000wart , time 0-60s;

[0075] c. Deposit the crystalline silicon wafer completed in step b by tubular PECVD to obtain a high-refractive-index silicon nitride anti-reflection film with a first-layer refractive index of 2.30-2.35. The PECVD parameters are set to: ammonia gas flow rate 4.5- 5.0slm, silane flow rate 1000-1100sccm, pressure 1650-1750mTor, RF power 5500-6500wart, switching ti...

Embodiment 2

[0087] The manufacturing process of the double 85 anti-PID polycrystalline solar cells comprises the following steps:

[0088] a. After cleaning the textured, diffused and etched crystalline silicon wafer, generate a layer of 2nm SiO on the surface of the crystalline silicon wafer through an ozone generator 2 Oxide film;

[0089] b. Put the crystalline silicon wafer completed in step a on the graphite boat through the loading and unloading system, and put it into the tubular PECVD for pre-deposition. The PECVD parameters are set as: ammonia gas flow rate 4.5-5.0slm, radio frequency power 5000-6000wart , time 0-60s;

[0090] c. Deposit the crystalline silicon wafer completed in step b by tubular PECVD to obtain a high-refractive-index silicon nitride anti-reflection film with a first-layer refractive index of 2.30-2.35. The PECVD parameters are set to: ammonia gas flow rate 4.5- 5.0slm, silane flow rate 1000-1100sccm, pressure 1650-1750mTor, RF power 5500-6500wart, switching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com