Method for preparing metal electrode on grapheme conductive film

A graphene film and metal electrode technology, which is applied in metal material coating process, electrical digital data processing, input/output process of data processing, etc., can solve problems such as low efficiency, inability to realize metal film, and affecting service life. Achieve the effects of simplifying the manufacturing process, reducing the process of high-temperature baking and curing slurry, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

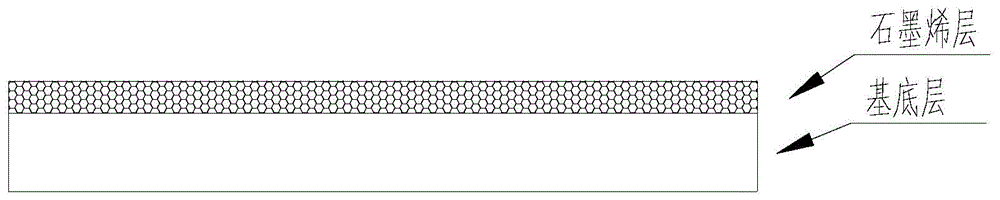

[0049] 1) The preparation of graphene on the growth material is carried out by chemical vapor deposition (CVD), using argon and nitrogen as protective gases, and methane and hydrogen are deposited at 1000 ° C, and then cooled to room temperature in the protective gas after deposition, Transfer graphene to the 188 μm PET base layer by thermal tape, and remove the growth material by etching, so that graphene is transferred to the base layer, as shown in figure 1 Structure.

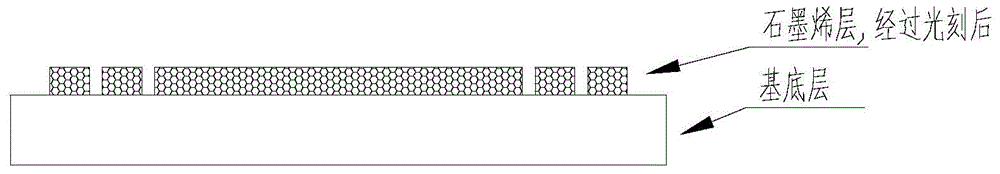

[0050] 2) Using a 1064nm, M^2 figure 2 Structure.

[0051] focus height

energy

speed

frequency

Number of passes

23.815mm

7W

2500

200K

1

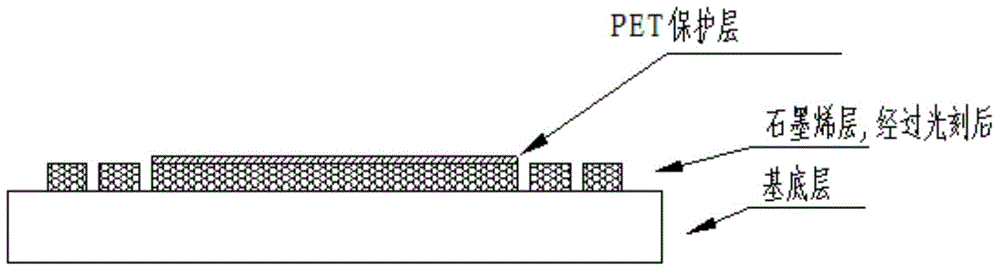

[0052] 3) Paste a protective layer on the part that does not need metal electrodes. The material of the protective layer is PET, and the adhesive layer is silica gel. image 3 Structure.

[0053] 4) Plating a layer of metal electrodes on the unprotected part by electroless plating.

[0054] The electroless plating ...

Embodiment 2

[0065] 1) The preparation of graphene on the growth material is carried out by chemical vapor deposition (CVD), using argon and nitrogen as protective gases, methane and hydrogen are deposited at 1000 ° C, and after deposition, it is cooled to room temperature in protective gas. Transfer graphene to the PET base layer of 188 μm by PMMA binder, remove the growth material by bubble stripping method, transfer graphene to the base layer, and obtain the following: Figure 6 Structure.

[0066] 2) A protective layer is attached to the part that does not require metal electrodes. The material of the protective layer is PET, and the adhesive layer is silicone. get as Figure 7 Structure.

[0067] 3) Plating a layer of metal electrodes on the unprotected part by means of electroplating.

[0068] The electroplating solution formula and process used are:

[0069] Nickel sulfate: 250g / L

[0070] Nickel chloride: 40g / L

[0071] Boric acid: 40g / L

[0072] Temperature: 55℃~65℃

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com